Overview of Additive Manufacture Tungsten Powder Pure Tungsten Spherical Tungsten Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Additive Manufacture Tungsten Powder Pure Tungsten Spherical Tungsten Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

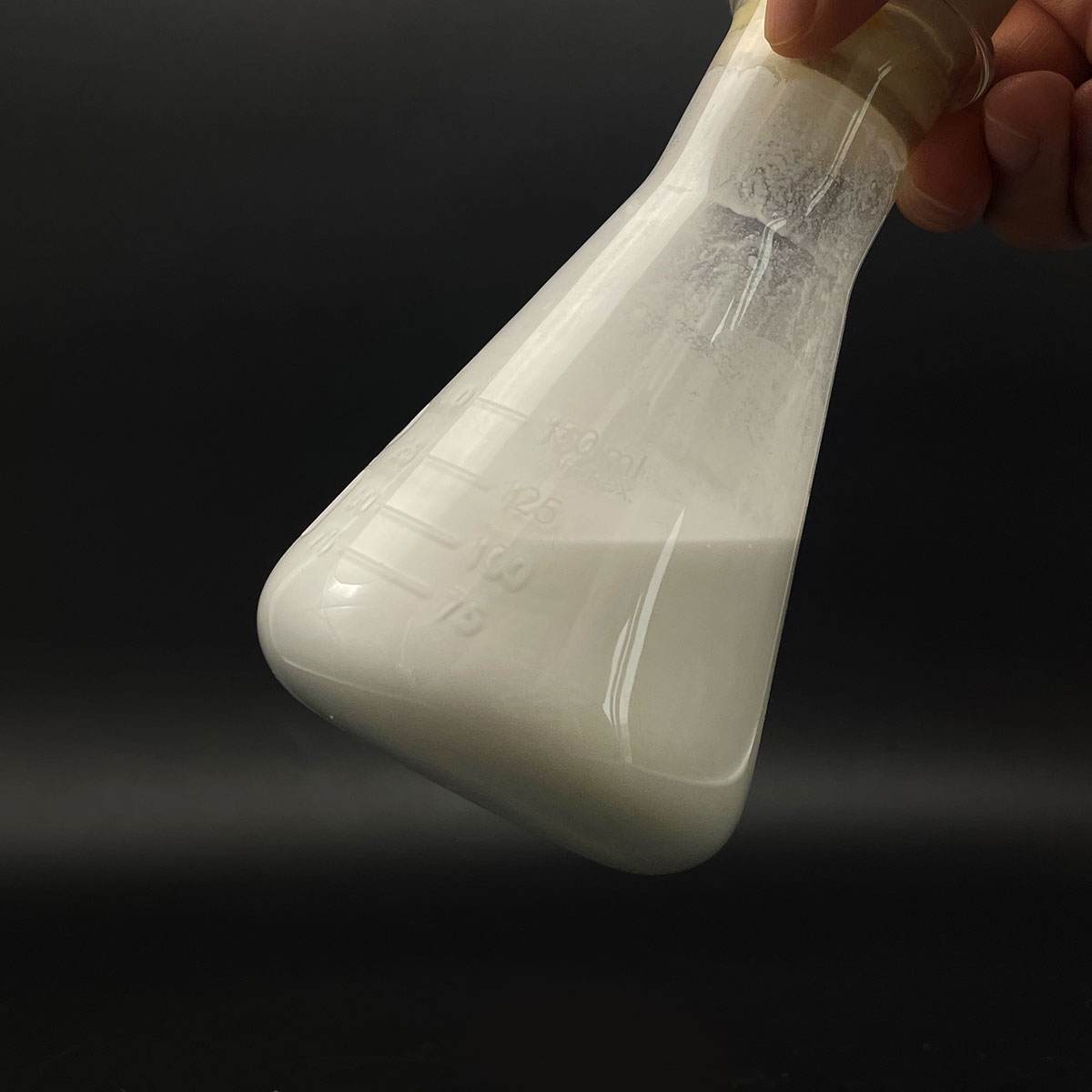

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Additive Manufacture Tungsten Powder Pure Tungsten Spherical Tungsten Powder)

Parameters of Additive Manufacture Tungsten Powder Pure Tungsten Spherical Tungsten Powder

Additive Manufacturing, also known as 3D printing, has revolutionized the way materials are processed and shaped into complex geometries. Tungsten, a dense, lustrous metal with an atomic number of 74, is one of the key elements in this innovative process due to its exceptional strength, high melting point, and resistance to corrosion. Pure tungsten powder, specifically, plays a pivotal role in additive manufacturing applications.

Tungsten spherical tungsten powder, characterized by its spherical shape, offers several advantages over other particle forms. The spherical shape allows for more efficient packing, resulting in better material utilization during the printing process. This leads to reduced waste and improved print resolution, as the particles tend to flow more smoothly, facilitating a uniform distribution of material within the build chamber.

The size of the tungsten powder particles is another critical parameter, typically ranging from 10 microns to 50 microns or even smaller, depending on the desired application and the specific 3D printer being used. Smaller particles enable higher surface area-to-volume ratios, enabling faster and more accurate bonding during the fusion process. Larger particles, on the other hand, may be more suitable for applications that require less fine detail or have a lower demand for resolution.

The purity of the tungsten powder is of utmost importance, as impurities can affect the mechanical properties and performance of the final product. High-purity tungsten powders, with a purity level of 99.9% or above, ensure minimal contamination and superior thermal stability, which is crucial for maintaining the integrity of the printed parts. Additionally, purity enhances the overall durability and resistance to wear and tear.

The density of tungsten, around 19.25 g/cm³, is one of its most notable attributes. This makes it ideal for applications where weight is a concern, such as aerospace, where every gram counts. Moreover, the high density contributes to the excellent heat conductivity and strength of tungsten-based components, making them suitable for use in extreme environments like high-temperature applications or high-pressure situations.

In terms of processing, tungsten powder for additive manufacturing often undergoes a special treatment called sintering, where particles are compacted under heat and pressure to form a cohesive structure. This process ensures that the final printed part possesses the desired mechanical properties, including high strength and hardness. Post-processing techniques like annealing can further refine the microstructure and enhance the performance of the tungsten-based components.

In conclusion, pure tungsten spherical powder is a key ingredient in additive manufacturing, offering benefits such as efficient packing, controlled particle size, high purity, and inherent material properties that make it ideal for demanding applications. As technology advances, the versatility and potential of tungsten in AM continue to expand, opening up new avenues for innovation in various industries, including aerospace, automotive, and energy production.

(Additive Manufacture Tungsten Powder Pure Tungsten Spherical Tungsten Powder)

FAQs of Additive Manufacture Tungsten Powder Pure Tungsten Spherical Tungsten Powder

Inquiry us