Overview of Additive manufacture niobium alloy metal hardening powder 3d printing c10

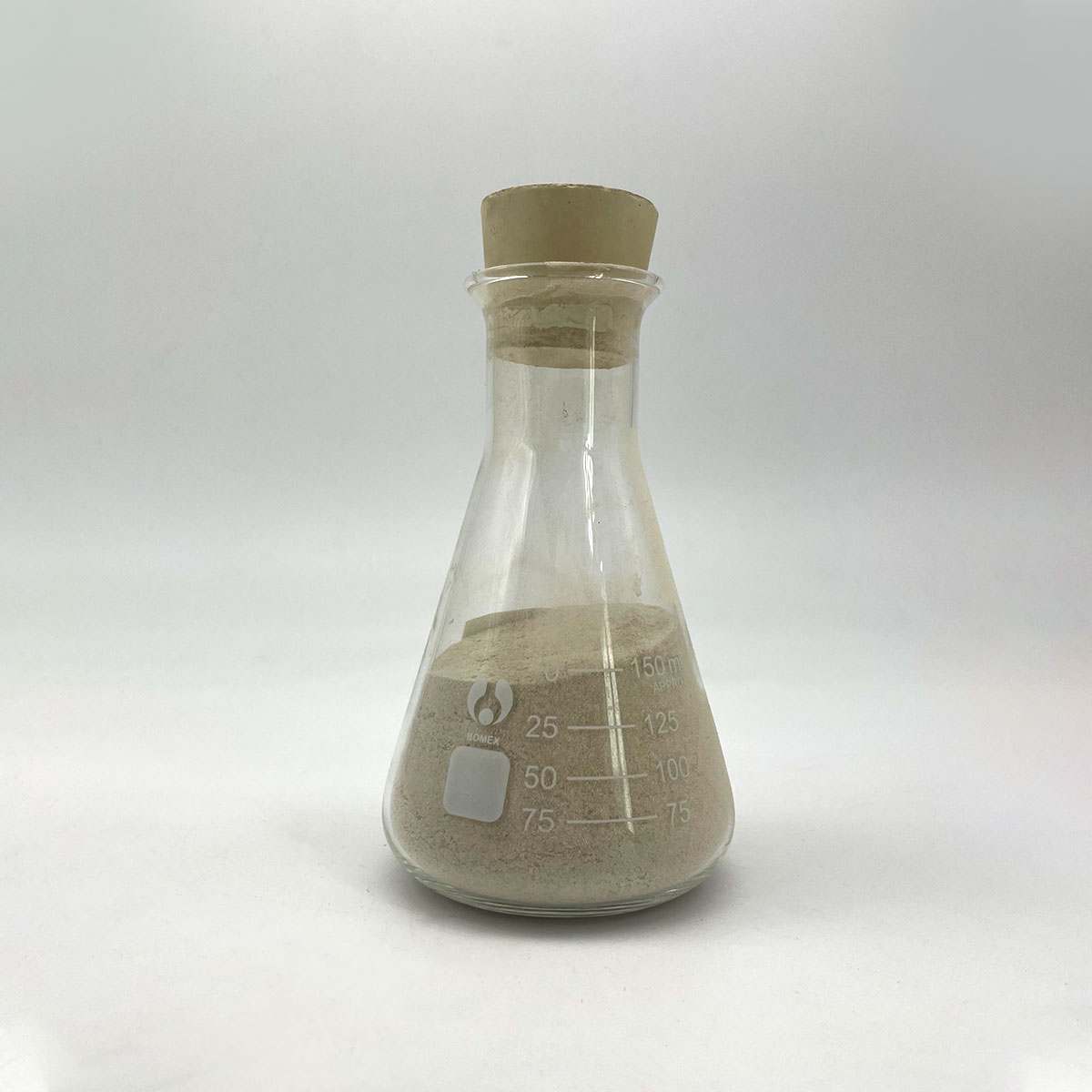

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Additive manufacture niobium alloy metal hardening powder 3d printing c10

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Additive manufacture niobium alloy metal hardening powder 3d printing c10)

Parameters of Additive manufacture niobium alloy metal hardening powder 3d printing c10

Additive Manufacturing, also known as 3D Printing, has revolutionized the way materials, including Niobium alloys, are processed and fabricated. Niobium, a superalloy with exceptional strength, ductility, and corrosion resistance, finds applications in various industries, from aerospace to medical devices due to its unique properties. When it comes to 3D printing niobium alloys, the C10 parameter plays a crucial role in ensuring optimal performance and quality.

C10 refers to a specific condition or setting within the additive manufacturing process for niobium alloys, which is often associated with the thermal history of the material during the printing. This parameter encompasses the combination of factors that influence the solidification and cooling rates, layer thickness, energy input, and post-processing treatments that affect the microstructure and mechanical properties of the final product.

The C10 parameter includes:

1. **Printing Temperature**: The temperature at which the niobium alloy powder is melted during the extrusion process. This temperature should be carefully controlled to ensure proper bonding between layers while maintaining the desired mechanical properties.

2. **Layer Thickness**: The thickness of each printed layer, which affects the cooling rate and subsequent microstructural development. Thicker layers may result in slower cooling, potentially leading to larger grains and weaker mechanical strength.

3. **Infill Density**: The percentage of solid material within the printed object, which influences the overall strength and structural integrity. Higher infill density generally leads to stronger parts but may require more time to print.

4. **Energy Input**: The amount of energy applied during the extrusion process, affecting the melt pool size and the ability to achieve uniform melting. Proper control ensures that the material is fully fused without overheating or undermelting.

5. **Powder Quality**: The particle size, shape, and purity of the niobium alloy powder are essential for achieving good adhesion between layers and minimizing porosity. High-quality powders result in better mechanical properties.

6. **Post-Processing Techniques**: After printing, heat treatment (annealing) is often performed to refine the microstructure and enhance the mechanical properties. The C10 parameter may include the parameters for this stage, such as temperature, time, and cooling rate.

7. **Material Composition**: The specific composition of the niobium alloy, including the addition of other elements like titanium or aluminum, can influence the C10 settings. Tailoring these elements can optimize the material’s properties for a particular application.

8. **Printer Settings**: Parameters specific to the 3D printer itself, such as nozzle diameter, print speed, and air pressure, also contribute to the C10 condition. Each machine may have its own optimal settings for niobium alloy prints.

Understanding and optimizing the C10 parameter is crucial for achieving repeatable and high-quality results when 3D printing with niobium alloys. It allows for the creation of complex geometries, lightweight components, and improved performance in demanding environments. As research and technology continue to evolve, the possibilities for 3D-printed niobium alloys will expand, unlocking new applications and pushing the boundaries of engineering.

(Additive manufacture niobium alloy metal hardening powder 3d printing c10)

FAQs of Additive manufacture niobium alloy metal hardening powder 3d printing c10

Inquiry us