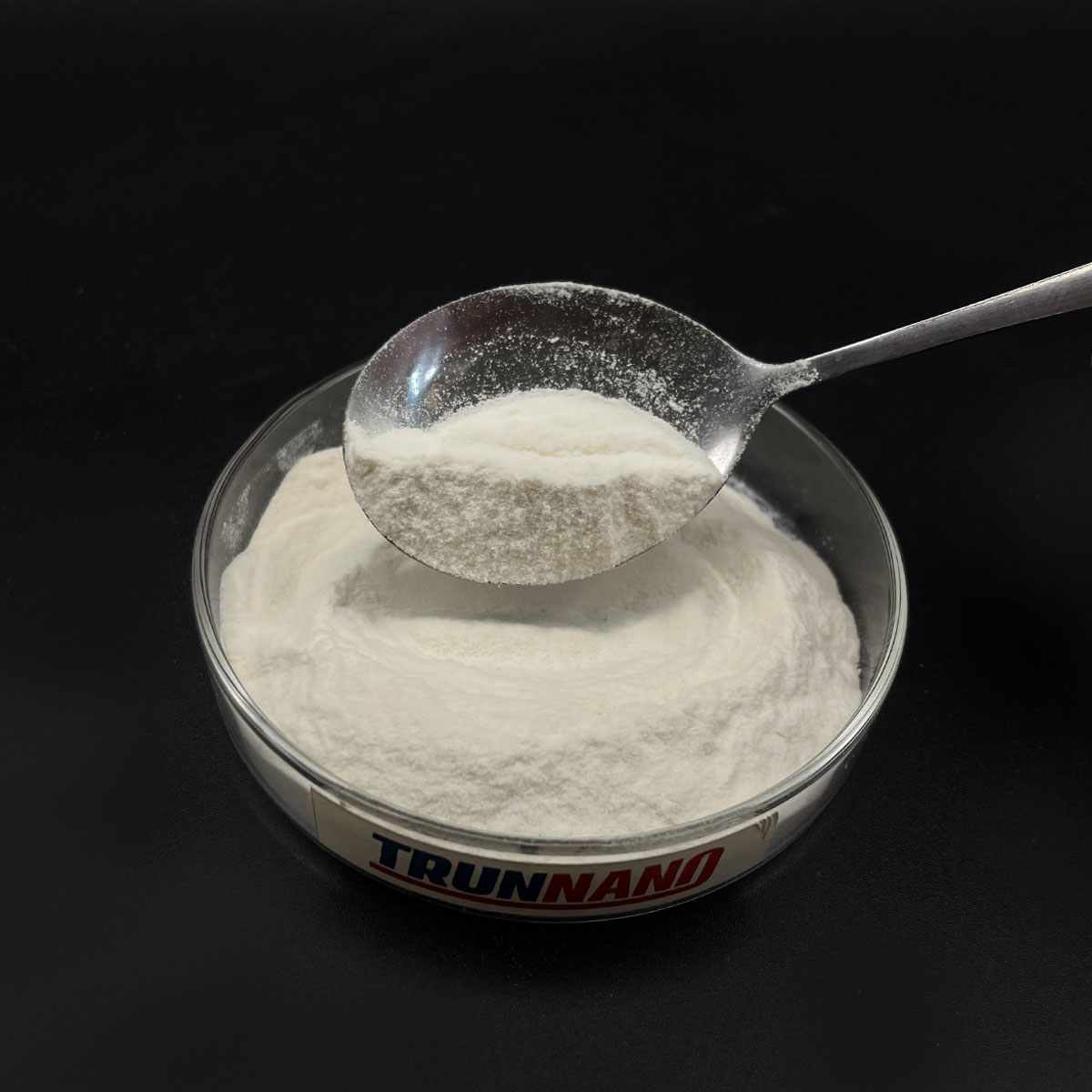

Overview of 99.99% Ultrafine Tantalum Pentoxide Ta2O5 Nanoparticles Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 99.99% Ultrafine Tantalum Pentoxide Ta2O5 Nanoparticles Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(99.99% Ultrafine Tantalum Pentoxide Ta2O5 Nanoparticles Powder)

Parameters of 99.99% Ultrafine Tantalum Pentoxide Ta2O5 Nanoparticles Powder

Title: Ultrafine Tantalum Pentoxide (Ta2O5) Nanoparticles: A Comprehensive Overview

Introduction

Tantalum pentoxide, also known as Ta2O5, is a highly sought-after inorganic material due to its exceptional electronic, optical, and thermal properties. At the nanoscale, it exhibits even more remarkable characteristics, making it a versatile component in various applications, including electronics, energy storage, and catalysis. This article delves into the key parameters of 99.99% ultrafine tantalum pentoxide nanoparticles, providing a detailed overview without adhering to a specific format.

Purity and Particle Size

The purity level of 99.99% ensures that the tantalum pentoxide nanoparticles are virtually free from impurities, which is crucial for maintaining their inherent properties and performance in various applications. The ultrafine particle size refers to particles having dimensions below 100 nanometers, typically in the range of 1-100 nm. This small size grants the material unique properties such as increased surface area, improved reactivity, and enhanced catalytic activity.

Crystal Structure and Morphology

The crystal structure of tantalum pentoxide nanoparticles is typically rutile or anatase, depending on the synthesis method. Rutile structure consists of a tetragonal lattice, while anatase has a cubic one. Ultrafine particles often exhibit a high degree of crystallinity and well-defined morphology, which contributes to their superior properties. TEM (Transmission Electron Microscopy) and SEM (Scanning Electron Microscopy) analyses are commonly used to study the morphology and particle size distribution.

Surface Area and Porosity

The high surface area and porosity of the 99.99% Ta2O5 nanoparticles are advantageous, as they increase the interaction with reactants in chemical processes and enhance the capacitance in electrochemical systems. Techniques like Brunauer-Emmett-Teller (BET) analysis are employed to quantify the surface area, revealing its significant impact on the material’s functionality.

Optical Properties

Nanocrystalline tantalum pentoxide exhibits unique optical properties, such as tunable bandgap and strong light absorption. As the particle size decreases, the bandgap narrows, which can be beneficial for optoelectronic applications like solar cells and photodetectors. The refractive index and extinction coefficient are also influenced by the nanostructure, affecting the material’s performance in optical devices.

Thermal Stability and Conductivity

Ultrafine tantalum pentoxide particles maintain their integrity over a wide temperature range, making them suitable for high-temperature applications. The thermal conductivity, which is influenced by the grain size and particle arrangement, plays a critical role in heat dissipation and thermal management. Nanostructured Ta2O5 typically exhibits higher thermal conductivity compared to bulk materials due to its reduced grain boundaries.

Catalytic Activity

The nanoscale nature of tantalum pentoxide enhances its catalytic properties, allowing it to act as a support for various metal catalysts or as an active component itself. It is known for its ability to catalyze reactions involving oxygen, hydrogen, and carbon compounds, making it a promising material in areas like environmental remediation, fuel cells, and automotive exhaust treatment.

Conclusion

In summary, 99.99% ultrafine tantalum pentoxide (Ta2O5) nanoparticles offer exceptional properties, including high purity, tunable size, diverse crystal structures, and enhanced performance in various applications. Their unique characteristics stem from their nanoscale dimensions, which influence their surface area, optical, thermal, and catalytic properties. Continued research and development in this field promise to unlock new opportunities for the integration of tantalum pentoxide nanoparticles into next-generation technologies.

(99.99% Ultrafine Tantalum Pentoxide Ta2O5 Nanoparticles Powder)

FAQs of 99.99% Ultrafine Tantalum Pentoxide Ta2O5 Nanoparticles Powder

Inquiry us