Overview of 3D Printing Powder Spherical Niobium Mo Ta W V Metal Powder for Additive Manufacturing

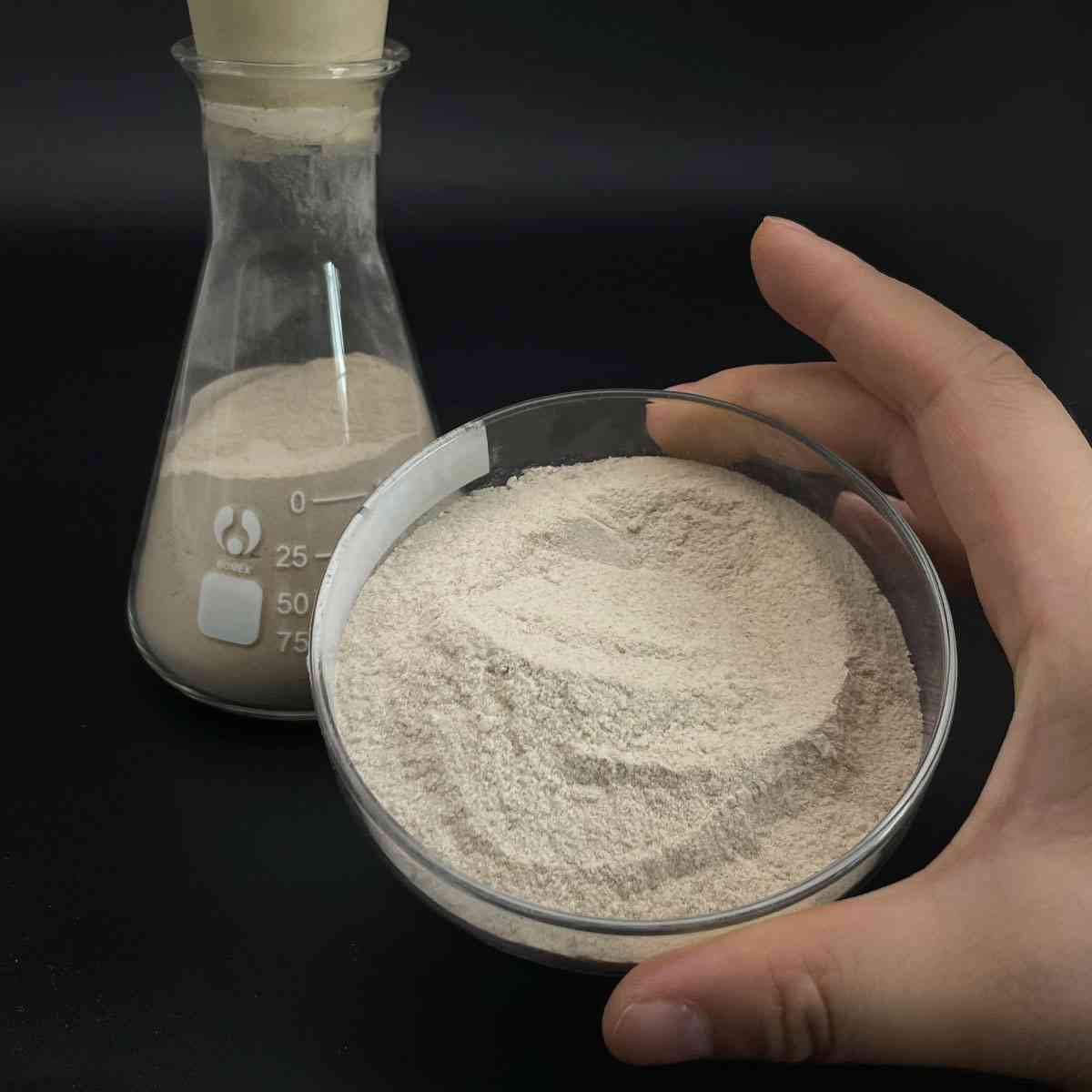

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 3D Printing Powder Spherical Niobium Mo Ta W V Metal Powder for Additive Manufacturing

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(3D Printing Powder Spherical Niobium Mo Ta W V Metal Powder for Additive Manufacturing)

Parameters of 3D Printing Powder Spherical Niobium Mo Ta W V Metal Powder for Additive Manufacturing

Title: High-Purity 3D Printing Spherical Niobium, Molybdenum, Tungsten, Vanadium Metal Powders for Advanced AM Applications

Introduction:

The rapid evolution of additive manufacturing (AM), also known as 3D printing, has opened up unprecedented possibilities in the realm of material science. One key component in this revolution is the use of high-performance metal powders, such as spherical niobium (Nb), molybdenum (Mo), tungsten (W), and vanadium (V) powders. These unique powders offer exceptional properties for various AM processes, including selective laser melting (SLM), electron beam melting (EBM), and binder jetting.

Spherical Powders:

The powders used in AM are typically in the form of spherical particles due to their inherent advantages over irregular shapes. Spherical particles ensure better flowability, reduced settling, and improved packing density, resulting in enhanced print quality, fewer defects, and increased build accuracy. The spherical shape also facilitates more uniform melting during the printing process, leading to homogeneous material distribution and enhanced mechanical properties in the final product.

Material Composition:

Our 3D printing metal powder blend consists of pure niobium, molybdenum, tungsten, and vanadium, each carefully selected for its specific characteristics. Niobium is known for its high strength-to-weight ratio and corrosion resistance, making it suitable for aerospace and medical applications. Molybdenum exhibits excellent thermal and wear resistance, while tungsten boasts unparalleled hardness and density, ideal for extreme conditions or high-precision components. Vanadium, with its high melting point, contributes to enhanced wear resistance and toughness.

Properties:

These powders possess a narrow particle size distribution, ensuring consistent print resolution and minimizing porosity. The high purity level ensures minimal impurities, resulting in superior mechanical properties and dimensional stability after post-processing. The metals’ high melting points allow for the creation of complex geometries and intricate structures that would be challenging using traditional manufacturing methods.

Processing Parameters:

The optimal processing parameters for these powders vary depending on the chosen AM technique. For instance, SLM requires precise control over laser power, scanning speed, and hatch spacing, while EBM necessitates monitoring electron beam energy and scan rates. The choice of powder bed temperature and cooling rates also plays a crucial role in achieving the desired microstructure and mechanical properties.

Environmental Sustainability:

As the demand for sustainable manufacturing practices grows, our 3D printing metal powders are designed with recyclability in mind. After use, they can be easily separated from the printed parts, reducing waste and promoting a circular economy.

Conclusion:

In summary, our spherical Niobium, Molybdenum, Tungsten, and Vanadium metal powders are a game-changer in the world of additive manufacturing. Their unique properties, combined with tailored processing parameters, enable the creation of high-performance components across various industries. As we continue to push the boundaries of AM technology, these powders serve as a cornerstone in realizing the full potential of this transformative manufacturing method.

(3D Printing Powder Spherical Niobium Mo Ta W V Metal Powder for Additive Manufacturing)

FAQs of 3D Printing Powder Spherical Niobium Mo Ta W V Metal Powder for Additive Manufacturing

Inquiry us