Overview of 2400C intermediate frequency induction furnce cemented carbide copper-tungsten alloy tungsten molybdenum alnico-cobalt permanent

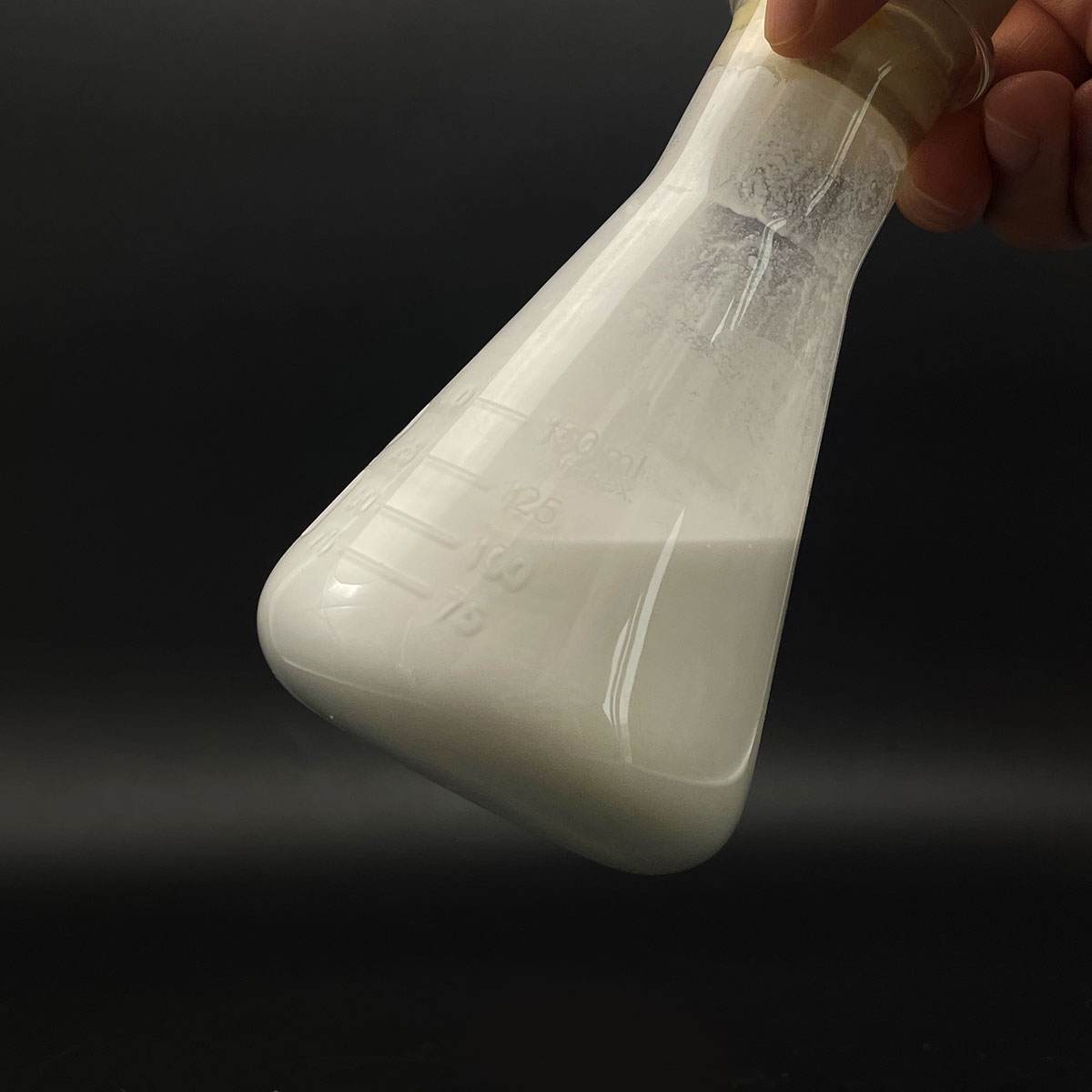

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 2400C intermediate frequency induction furnce cemented carbide copper-tungsten alloy tungsten molybdenum alnico-cobalt permanent

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(2400C intermediate frequency induction furnce cemented carbide copper-tungsten alloy tungsten molybdenum alnico-cobalt permanent)

Parameters of 2400C intermediate frequency induction furnce cemented carbide copper-tungsten alloy tungsten molybdenum alnico-cobalt permanent

A 2400C Intermediate Frequency Induction Furnace is a specialized piece of equipment utilized in the metalworking industry, particularly for the production and melting of high-temperature materials like cemented carbide, copper-tungsten alloys, tungsten molybdenum, and alnico-cobalt permanent magnets. This furnace operates using an intermediate frequency (IF) heating method, which offers several advantages over other induction technologies.

The key parameters of this furnace include:

1. Operating Temperature: The furnace can reach temperatures up to 2400 degrees Celsius, making it ideal for processing materials that require extreme heat to achieve their desired properties. This temperature range allows for the homogenization and melting of even the most challenging compositions.

2. Heating Efficiency: Intermediate frequency induction furnaces are known for their high efficiency, converting a large portion of electrical energy into thermal energy. This efficiency reduces energy costs and minimizes environmental impact.

3. Frequency: The “intermediate” in IF refers to the frequency used, typically between 10 kHz and 1 MHz. This frequency allows for rapid and uniform heating, as well as reduced eddy current losses compared to low-frequency furnaces.

4. Quenching Capability: Some models may feature rapid quenching systems, allowing for the rapid cooling of molten materials after processing, which is crucial for forming hard, wear-resistant compounds in cemented carbide and other alloys.

5. Process Control: Advanced digital control systems enable precise temperature monitoring and control, ensuring consistent product quality and minimizing the risk of overheating or underheating. These systems often include data logging and automation features.

6. Loading Capacity: Depending on the design, the furnace can accommodate various load sizes, from small-scale batch processes to larger continuous casting applications. The capacity is usually specified in terms of weight or volume, accommodating a wide range of material forms.

7. Insulation: The furnace is designed with robust insulation materials to minimize heat loss and maintain optimal operating conditions. This includes high-temperature refractory linings and efficient heat shields.

8. Safety Measures: Ensuring safety is paramount in any furnace operation. The 2400C IF furnace will have safety features such as interlocks, emergency shutdowns, and proper ventilation to protect operators and prevent accidents.

9. Customization: Furnaces of this type can be customized to meet specific material processing requirements, incorporating various heating elements, crucibles, or even specialized crucible designs for different alloys.

In conclusion, the 2400C Intermediate Frequency Induction Furnace is a versatile and powerful tool for the production of high-performance materials. Its ability to handle demanding alloys and its advanced features make it an essential piece of equipment in industries that rely on precision and high-temperature processes, such as aerospace, automotive, and cutting tools manufacturing.

(2400C intermediate frequency induction furnce cemented carbide copper-tungsten alloy tungsten molybdenum alnico-cobalt permanent)

FAQs of 2400C intermediate frequency induction furnce cemented carbide copper-tungsten alloy tungsten molybdenum alnico-cobalt permanent

Inquiry us