Overview of Molybdenum iron powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Molybdenum iron powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

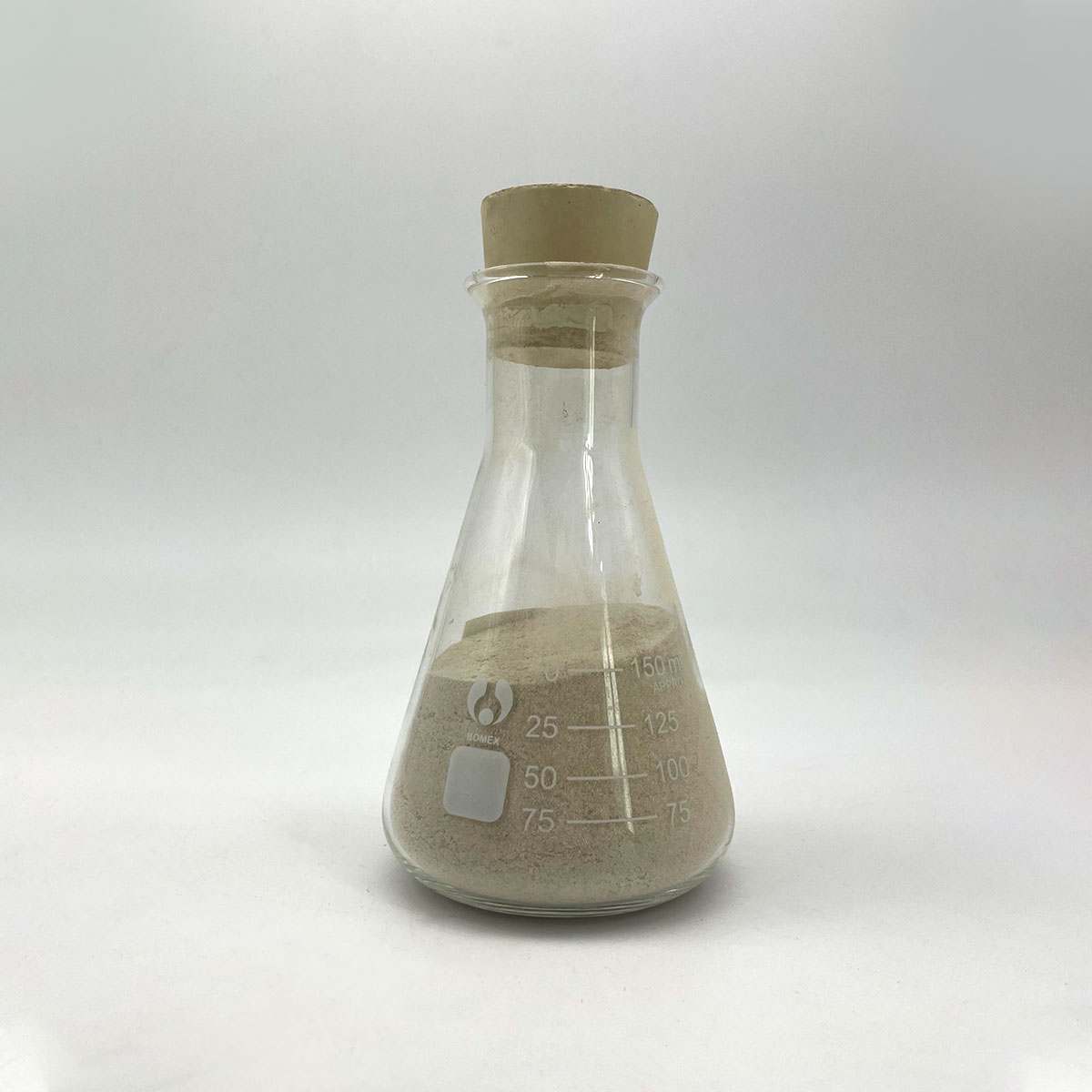

(Molybdenum iron powder)

Parameters of Molybdenum iron powder

Molybdenum iron powder, also known as Mo-Fe or Molybdenum alloyed iron powder, is a high-performance material that combines the unique properties of molybdenum with those of iron. This composite powder finds applications in various industries due to its exceptional strength, wear resistance, and corrosion tolerance.

Molybdenum, a chemical element with the symbol Mo and atomic number 42, is known for its high melting point, excellent thermal stability, and superior strength at elevated temperatures. It enhances the hardness and toughness of iron by forming strong intermetallic compounds with the matrix. The addition of molybdenum to iron powder improves its resistance to fatigue, wear, and oxidation, making it suitable for demanding environments like automotive, aerospace, and manufacturing sectors.

The iron component in the mixture is typically low-carbon steel or high-carbon steel, depending on the desired properties. Low-carbon steel provides better machinability, while high-carbon steel offers increased hardness and wear resistance. The molybdenum content can vary from 1% to over 10%, with higher percentages resulting in stronger and more heat-resistant materials.

Molybdenum iron powders are produced through a variety of processes, including atomization, gas atomization, and mechanical milling. These methods ensure a homogeneous distribution of molybdenum within the iron matrix, creating a fine-grained structure that improves the powder’s flowability and densification during consolidation.

One of the key characteristics of molybdenum iron powder is its ability to form strong bonds during sintering, which is the process of compacting and bonding the particles together under heat and pressure. This results in a dense, fully dense material with improved mechanical properties compared to conventional iron alloys. Sintering temperatures for Mo-Fe powders are generally between 1,200°C to 1,500°C, depending on the composition.

In terms of performance, molybdenum iron powders exhibit excellent tribological properties, meaning they have low coefficients of friction and good wear resistance. This makes them ideal for applications where sliding contacts are frequent, such as bearings, gears, and engine components. They also possess good magnetic properties, which are beneficial in electromagnetic systems.

Environmental aspects are another area where molybdenum iron powder stands out. Due to its corrosion resistance, it reduces the need for surface coatings, leading to lower maintenance costs and reduced environmental impact. Additionally, the powder’s high melting point allows for the production of parts with a longer service life.

In summary, molybdenum iron powder is a versatile material that combines the strength and durability of iron with the unique benefits of molybdenum. Its wide range of applications, from automotive to aerospace, highlights the importance of its exceptional properties, including wear resistance, corrosion tolerance, and sinterability. As technology advances, the demand for high-performance materials like molybdenum iron powder continues to grow, driving innovation in various industries.

(Molybdenum iron powder)

FAQs of Molybdenum iron powder

Inquiry us