Overview of Factory High purity molybdenum trioxide reagent 99.9%Min CAS1313-27-5 MoO3 EINECS215-204-7

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory High purity molybdenum trioxide reagent 99.9%Min CAS1313-27-5 MoO3 EINECS215-204-7

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory High purity molybdenum trioxide reagent 99.9%Min CAS1313-27-5 MoO3 EINECS215-204-7)

Parameters of Factory High purity molybdenum trioxide reagent 99.9%Min CAS1313-27-5 MoO3 EINECS215-204-7

Title: High Purity Molybdenum Trioxide (MoO3) Reagent: A Key Ingredient for Advanced Applications

Introduction:

Molybdenum trioxide, with the chemical formula MoO3 and the CAS number 1313-27-5, is a highly sought-after inorganic compound in the chemical industry due to its exceptional purity level of at least 99.9%. This versatile compound, also known by its EINECS number 215-204-7, plays a crucial role in various applications across numerous sectors, from electronics and aerospace to energy production and environmental remediation.

Properties:

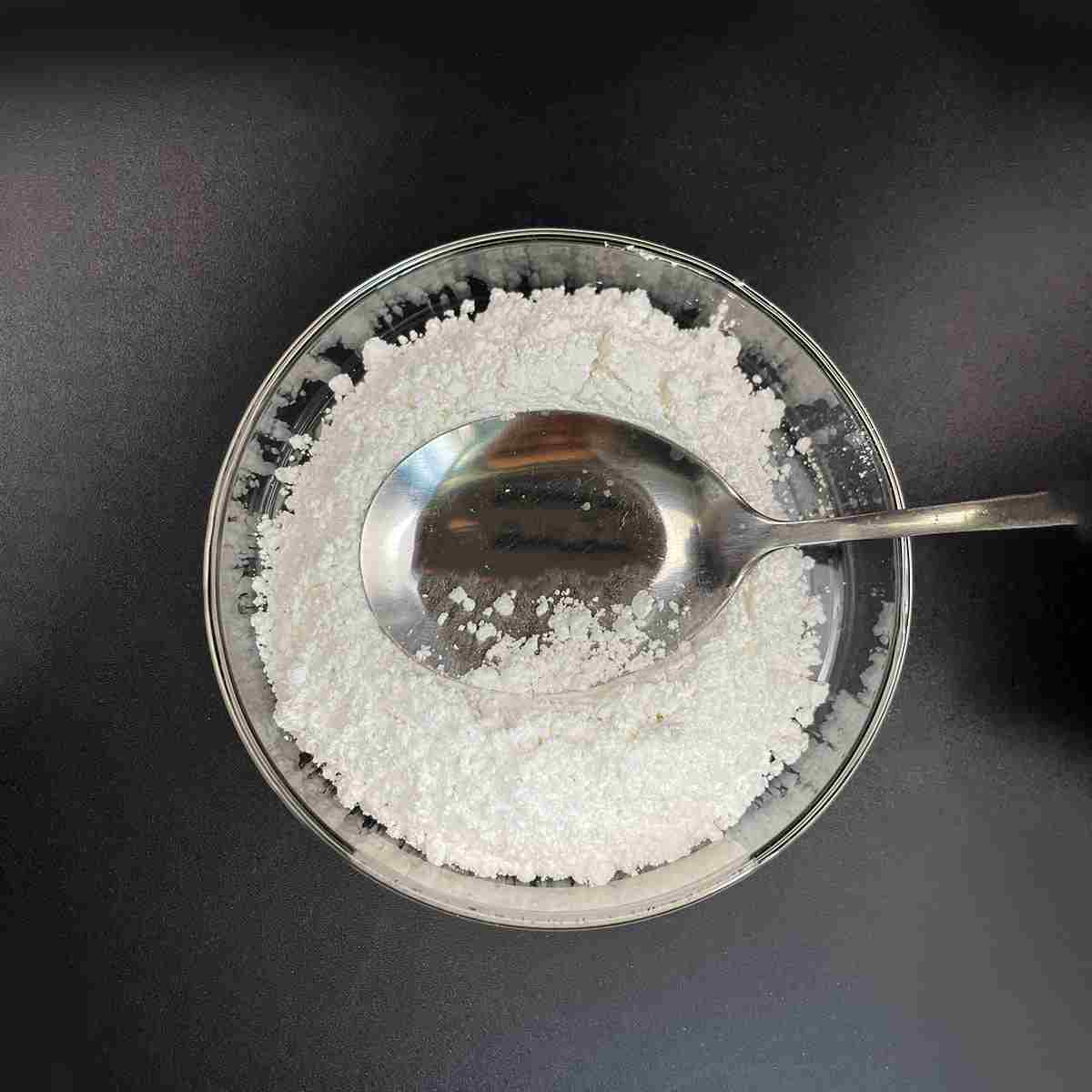

Molybdenum trioxide is a white or off-white crystalline solid, which is odorless and non-flammable. It has a high melting point, around 2825°C, making it resistant to thermal degradation. The compound is moisture-sensitive, absorbing water vapor from the atmosphere, so it is often stored in anhydrous conditions to maintain its purity. Its chemical stability allows it to react with metals, acids, and bases, making it a versatile catalyst in numerous chemical reactions.

Applications:

1. Electronics and Semiconductors:

In the semiconductor industry, MoO3 is used as a dopant to enhance the properties of materials like tungsten trioxide (WO3) in thin film transistors, improving their conductivity and performance. It also serves as a surface treatment agent for silicon wafers, enhancing their adhesion to other layers during fabrication.

2. Catalysis:

Molybdenum trioxide is an essential component in various catalysts, particularly in the automotive industry for low-emission catalysts. It promotes the conversion of harmful pollutants like carbon monoxide and nitrogen oxides into less harmful substances during combustion. Additionally, it finds applications in petrochemical processes, such as hydrodesulfurization and hydrocracking.

3. Energy Production:

In solar cells, MoO3 is used as a transparent conducting oxide (TCO), allowing light to pass through while maintaining electrical conductivity. It improves the efficiency of thin-film solar panels by facilitating the transport of charge carriers.

4. Environmental Remediation:

Molybdenum trioxide is employed in the treatment of wastewater, where it helps remove heavy metals like arsenic and mercury from contaminated water. Its ability to form complexes with these contaminants makes it an effective adsorbent in water purification processes.

5. Glass and Ceramic Manufacturing:

As a refractory material, MoO3 is used in glass and ceramic industries to increase their strength, thermal stability, and resistance to corrosion. It is also used in the production of high-performance ceramics, such as molybdenum carbide and molybdenum disilicide.

6. Agriculture and Soil Fertility:

MoO3 is added to fertilizers as a source of molybdenum, a micronutrient essential for plant growth, particularly in soil with low molybdenum content. It enhances plant resistance to diseases and stress, contributing to overall crop productivity.

Conclusion:

High purity molybdenum trioxide, with its exceptional properties and widespread applications, is a critical reagent in modern chemistry and technology. Its high purity ensures reliable performance and effectiveness in various industries, making it a valuable commodity. As research and development continue to advance, the importance of this compound will only grow, driving innovation and driving the future of numerous industrial sectors.

(Factory High purity molybdenum trioxide reagent 99.9%Min CAS1313-27-5 MoO3 EINECS215-204-7)

FAQs of Factory High purity molybdenum trioxide reagent 99.9%Min CAS1313-27-5 MoO3 EINECS215-204-7

Inquiry us