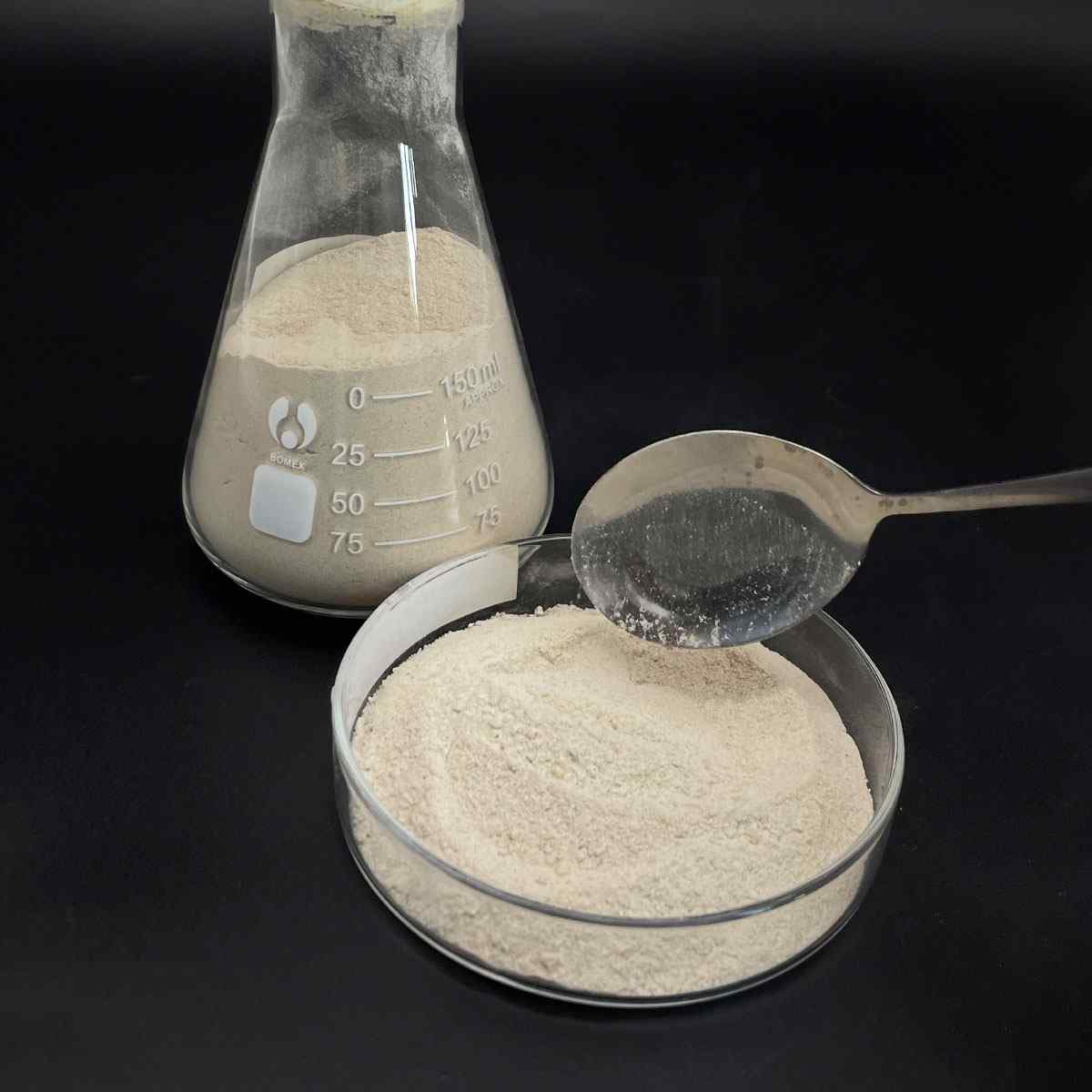

Overview of Molybdenum disulfide 1317-33-5

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Molybdenum disulfide 1317-33-5

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Molybdenum disulfide 1317-33-5)

Parameters of Molybdenum disulfide 1317-33-5

Molybdenum disulfide, also known by its chemical formula MoS2, is a fascinating and versatile compound that has garnered significant attention in various scientific disciplines due to its unique properties. With the CAS registry number 1317-33-5, this material belongs to the transition metal dichalcogenides family, which consists of compounds formed by molybdenum (Mo) and sulfur (S) atoms.

First discovered in 1869, MoS2 is a layered crystal structure, where molybdenum atoms are sandwiched between layers of sulfur atoms, creating a trigonal prismatic arrangement. This atomic configuration gives rise to its characteristic lamellar or “book-like” appearance. At room temperature, it exists as a solid with a hexagonal lattice, known as the 2H phase.

The key feature of molybdenum disulfide is its inherent electrical conductivity, particularly when in the form of few-layer or single-layer sheets, commonly referred to as MoS2 nanosheets. These nanosheets exhibit both metallic and semiconducting behavior depending on their thickness. As an insulator in bulk form, it transitions into a semiconductor with a bandgap of around 1.2 to 1.5 electron volts when thinned down, making it suitable for applications in electronic devices.

One of the most intriguing aspects of MoS2 is its extraordinary mechanical strength and flexibility. It possesses an impressive tensile strength of over 130 gigapascals, which is higher than steel, yet it remains lightweight and flexible. This combination of properties makes it a promising candidate for use in flexible electronics, aerospace, and even wearable technology.

Another remarkable property of MoS2 is its catalytic activity, particularly in the field of heterogeneous catalysis. The presence of the molybdenum atom in its structure allows it to act as a catalyst for various chemical reactions, such as hydrogenation, oxidation, and dehydrogenation. This versatility makes it useful in industries like petrochemicals, automotive, and renewable energy production.

Furthermore, MoS2 has shown promise in optoelectronics and photonics. Its semiconducting nature and strong light-matter interaction make it a potential material for photodetectors, solar cells, and even valleytronics, where the spin and valley states of electrons can be manipulated. Research is ongoing to explore the potential of MoS2 for next-generation optoelectronic devices.

In recent years, MoS2 has gained significant attention for its potential applications in energy storage, specifically in lithium-ion batteries and supercapacitors. The material’s large surface area, high capacity, and good electrochemical stability make it an attractive electrode material. Additionally, its ability to form van der Waals heterostructures with other 2D materials has opened up possibilities for novel device architectures.

In summary, molybdenum disulfide (CAS number 1317-33-5) is a multifaceted material with extraordinary properties that span across different scientific domains. Its unique electronic, mechanical, and catalytic characteristics have led to extensive research and development efforts, positioning it as a key component in various technological advancements. As scientists continue to unravel its full potential, MoS2 holds great promise for future innovations in areas such as electronics, energy, and materials science.

(Molybdenum disulfide 1317-33-5)

FAQs of Molybdenum disulfide 1317-33-5

Inquiry us