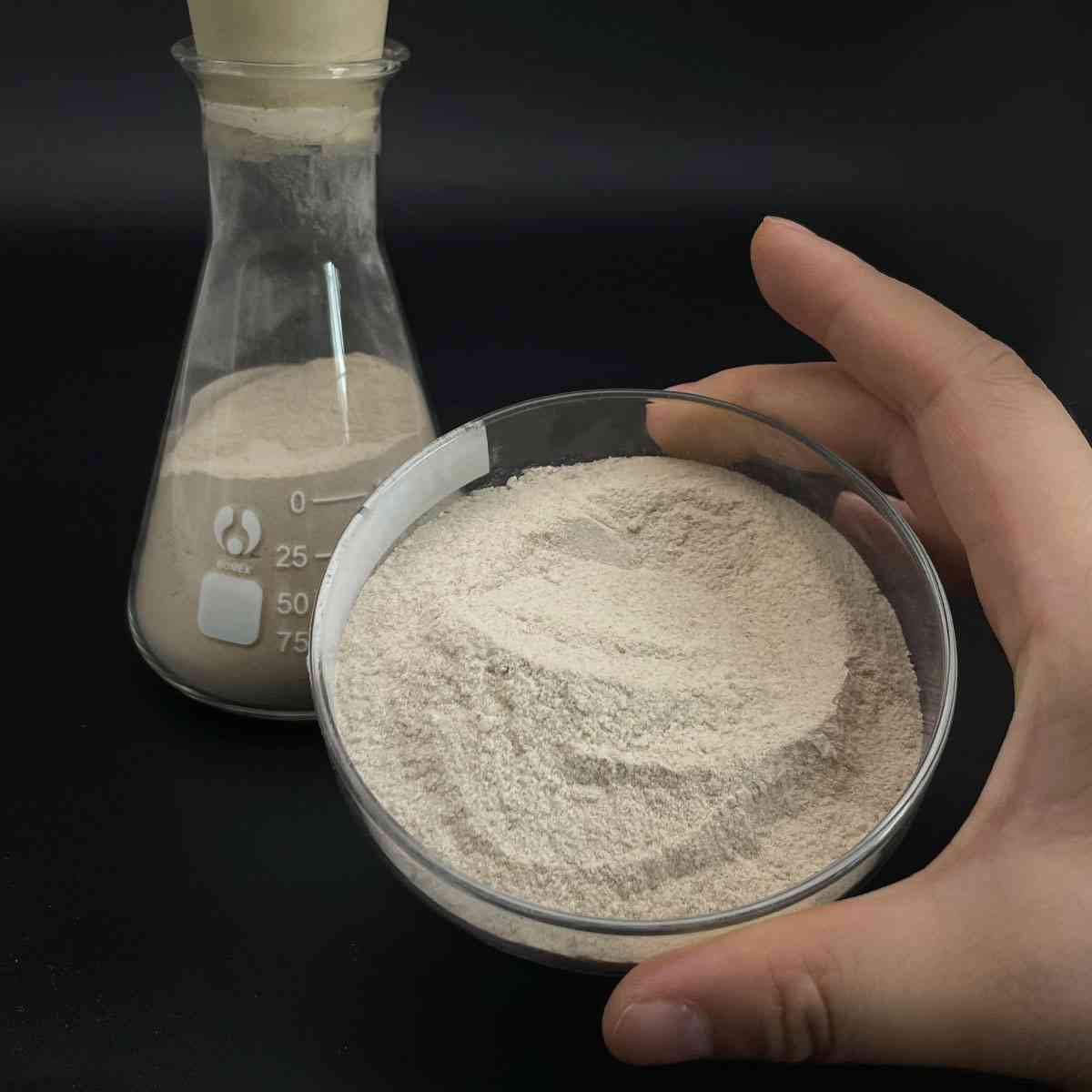

Overview of Single Layer Nano Molybdenum Disulfide Dispersion Monolayer MoS2 Liquid with Concentration 0.1mg/ml

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Single Layer Nano Molybdenum Disulfide Dispersion Monolayer MoS2 Liquid with Concentration 0.1mg/ml

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Single Layer Nano Molybdenum Disulfide Dispersion Monolayer MoS2 Liquid with Concentration 0.1mg/ml)

Parameters of Single Layer Nano Molybdenum Disulfide Dispersion Monolayer MoS2 Liquid with Concentration 0.1mg/ml

Title: Single-Layer Molybdenum Disulfide (MoS2) Nanodispersion: A High-Volume Liquid Solution with 0.1 mg/ml Concentration

Introduction

Molybdenum disulfide (MoS2), a two-dimensional (2D) transition metal dichalcogenide, has garnered significant attention in recent years due to its exceptional electronic, optical, and mechanical properties. This single-layer material holds promise for various applications, including optoelectronics, energy storage, and catalysis. One of the key aspects in utilizing MoS2’s potential is its dispersion as a monolayer in a liquid solution. This research focuses on a high-volume liquid dispersion of monolayer MoS2 with a concentration of 0.1 mg/ml.

Preparation and Synthesis

The synthesis of monolayer MoS2 involves a combination of chemical vapor deposition (CVD) and exfoliation techniques. Starting from bulk molybdenum tri sulfide (MoS3), the material undergoes a controlled reduction process, resulting in the formation of MoS2 flakes. These flakes are then separated into individual layers through sonication or mechanical exfoliation in a suitable solvent, such as N-methyl-2-pyrrolidone (NMP) or isopropyl alcohol (IPA).

Characterization

The dispersion of MoS2 monolayers is characterized using various analytical techniques. Raman spectroscopy confirms the presence of monolayer MoS2 by identifying the characteristic D and G bands, while atomic force microscopy (AFM) provides insights into the layer-by-layer structure and thickness. UV-Vis absorption spectroscopy reveals the optical properties, with a strong absorbance peak at the exciton edge, which is a signature of monolayer MoS2. The zeta potential measurements indicate a stable colloidal suspension with a well-defined surface charge, ensuring long-term stability of the dispersion.

Properties and Applications

The 0.1 mg/ml concentration of MoS2 monolayer dispersion offers a balance between high material content and manageable handling. At this concentration, the MoS2 flakes maintain their individuality, minimizing aggregation that could compromise their performance. The liquid nature of the dispersion allows for easy integration into various substrates through spin coating, drop casting, or other deposition methods.

In terms of applications, the monolayer MoS2 dispersion can be employed in thin-film transistors for flexible electronics, photodetectors for solar cells, and sensors for detecting gases or biomolecules due to its strong chemical reactivity. Additionally, the large surface area of monolayer MoS2 enhances its catalytic activity, making it suitable for energy storage devices like lithium-ion batteries and fuel cells.

Conclusion

In summary, the single-layer MoS2 nanodispersion with a concentration of 0.1 mg/ml represents a valuable material platform for exploring the unique properties of 2D MoS2 in practical applications. Its facile synthesis, stable colloidal properties, and versatile dispersion methods make it an attractive choice for researchers and engineers seeking to harness the full potential of this atomically thin material. Future work will focus on optimizing the dispersion techniques and exploring new applications in various fields where MoS2’s extraordinary properties can make a significant impact.

(Single Layer Nano Molybdenum Disulfide Dispersion Monolayer MoS2 Liquid with Concentration 0.1mg/ml)

FAQs of Single Layer Nano Molybdenum Disulfide Dispersion Monolayer MoS2 Liquid with Concentration 0.1mg/ml

Inquiry us