Overview of High purity Niobium Powder, 99.9% min purity

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High purity Niobium Powder, 99.9% min purity

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

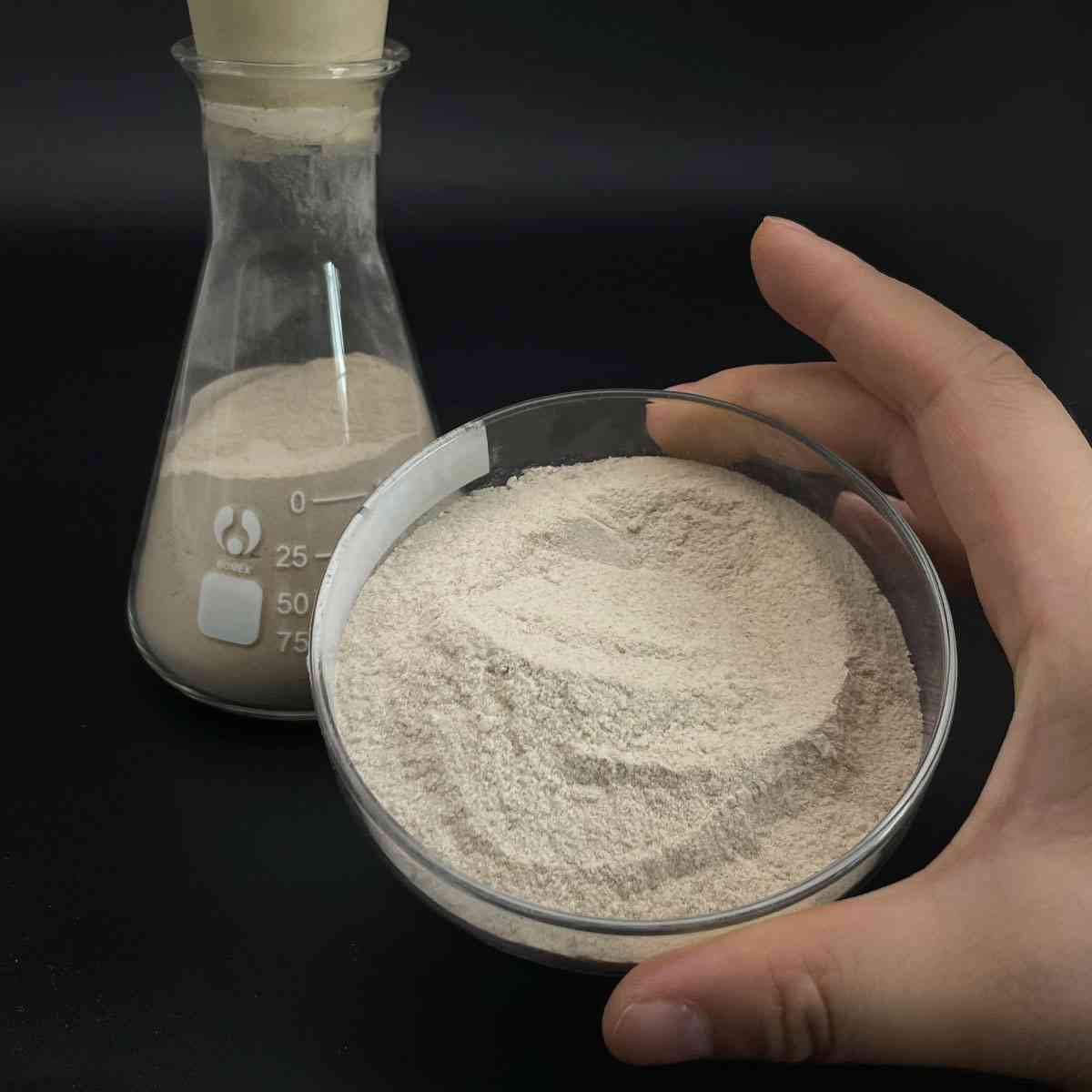

(High purity Niobium Powder, 99.9% min purity)

Parameters of High purity Niobium Powder, 99.9% min purity

Niobium powder, with a minimum purity of 99.9%, is a highly sought-after material in various industries due to its exceptional properties and versatility. This pure form of niobium ensures a high level of quality and performance in applications where precision and reliability are paramount.

Niobium, also known as columbium, is a chemical element with the symbol Nb and atomic number 41. It belongs to the tantalum group in the periodic table and is characterized by its strong metallic luster and corrosion resistance. At this high purity level, it exhibits minimal impurities, which significantly reduces the risk of contamination and enhances its inherent properties.

One of niobium’s key features is its superconducting capability. When cooled below a certain critical temperature, it can conduct electricity with zero resistance, making it ideal for applications in cryogenics, magnetic resonance imaging (MRI), and power transmission lines. The 99.9% purity ensures that these superconducting properties are optimized, enabling more efficient energy transfer and reduced energy losses.

In addition to superconductivity, niobium possesses excellent mechanical strength, high thermal conductivity, and a low magnetic susceptibility. These attributes make it suitable for aerospace, nuclear, and automotive industries, where lightweight yet durable components are essential. For instance, it finds use in the manufacturing of turbine blades, rocket engines, and nuclear reactor parts, where its strength-to-weight ratio and heat resistance play a crucial role.

Furthermore, niobium is an important component in the production of advanced alloys, such as Inconel and Hastelloy, which are used in high-temperature and high-pressure environments. The 99.9% pure powder allows for better alloy homogeneity and improved performance in demanding applications like jet engine components or chemical processing equipment.

In the field of electronics, niobium is utilized in microelectronics and microwave devices due to its ability to maintain stability at high frequencies. Its low loss tangent and high dielectric constant contribute to the development of high-performance filters, resonators, and antennas.

The absence of any specific format in the niobium powder means that it is available in a variety of particle sizes, from sub-micron to coarse powders, to cater to different processing techniques and requirements. These include spray pyrolysis, sputtering, or even traditional casting methods, enabling manufacturers to choose the most appropriate form for their manufacturing processes.

In conclusion, high purity niobium powder, with a 99.9% minimum purity, is a critical material in modern technology due to its unique properties and wide range of applications. Its superconducting capabilities, combined with its mechanical strength and corrosion resistance, make it indispensable in industries ranging from aerospace to electronics. The availability of various particle sizes further enhances its adaptability to diverse manufacturing needs. As technology continues to advance, the demand for this pure niobium powder is expected to grow, driving research and innovation in numerous sectors.

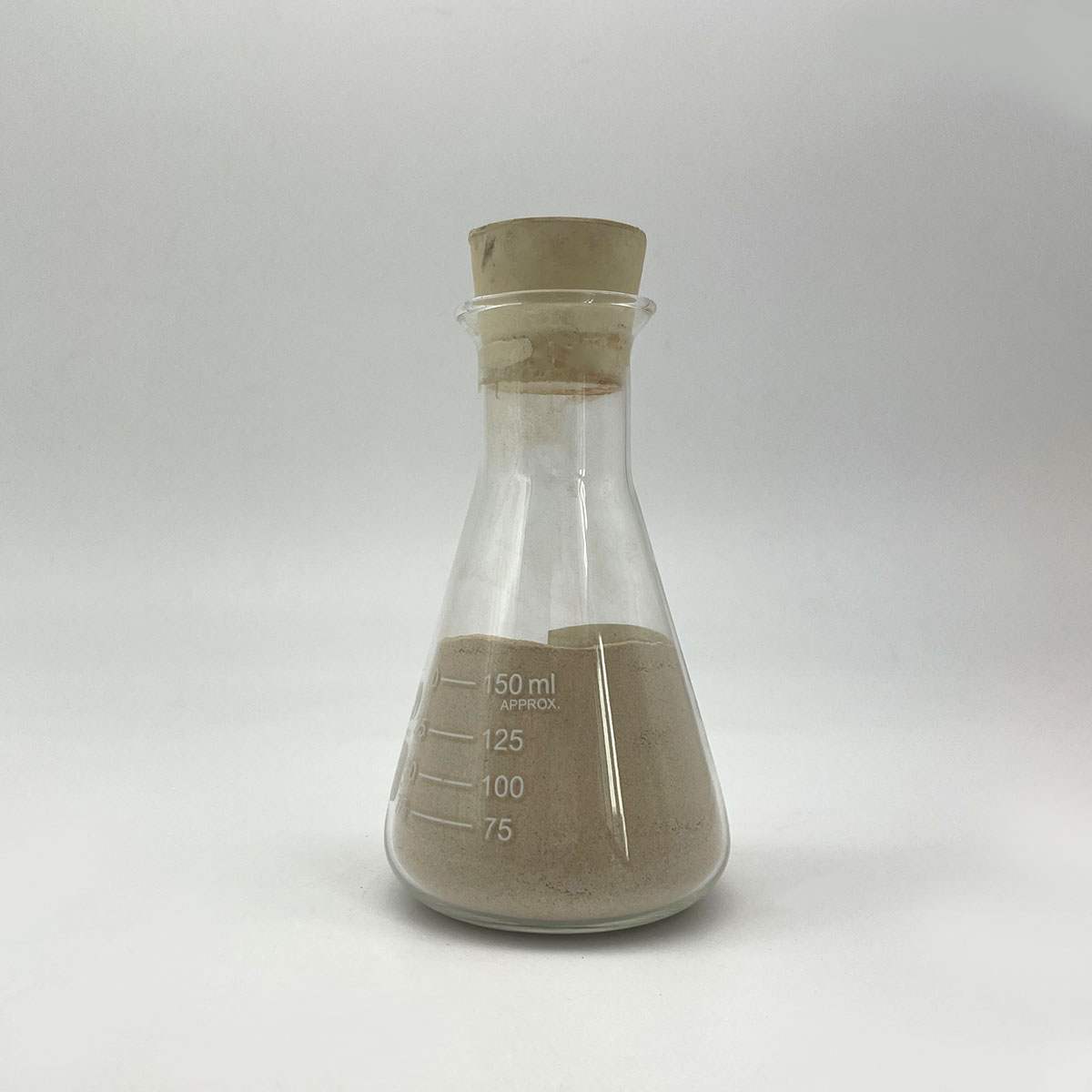

(High purity Niobium Powder, 99.9% min purity)

FAQs of High purity Niobium Powder, 99.9% min purity

Inquiry us