Overview of 3D Printing Metal Powder 99.9% Spherical Element Tantalum Ta Powder Spherical Tantalum Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 3D Printing Metal Powder 99.9% Spherical Element Tantalum Ta Powder Spherical Tantalum Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(3D Printing Metal Powder 99.9% Spherical Element Tantalum Ta Powder Spherical Tantalum Powder)

Parameters of 3D Printing Metal Powder 99.9% Spherical Element Tantalum Ta Powder Spherical Tantalum Powder

3D Printing with Metal Powders: A Focus on High-Purity Spherical Tantalum (Ta) Powder

In the realm of modern manufacturing, three-dimensional (3D) printing has emerged as a transformative technology, particularly in the realm of metal fabrication. Among the numerous metals available for this process, tantalum (Ta), known for its exceptional strength, corrosion resistance, and high melting point, stands out. This article delves into the specifics of using 99.9% spherical tantalum powder for 3D printing, highlighting its unique properties and the benefits it brings to the industry.

Tantalum is a rare, lustrous transition metal found naturally in trace amounts in the Earth’s crust. It boasts an impressive melting point of around 3,270°C, making it suitable for applications requiring extreme durability and heat resistance. The purity level of 99.9% ensures a consistently high-quality material that minimizes impurities and enhances the final product’s performance.

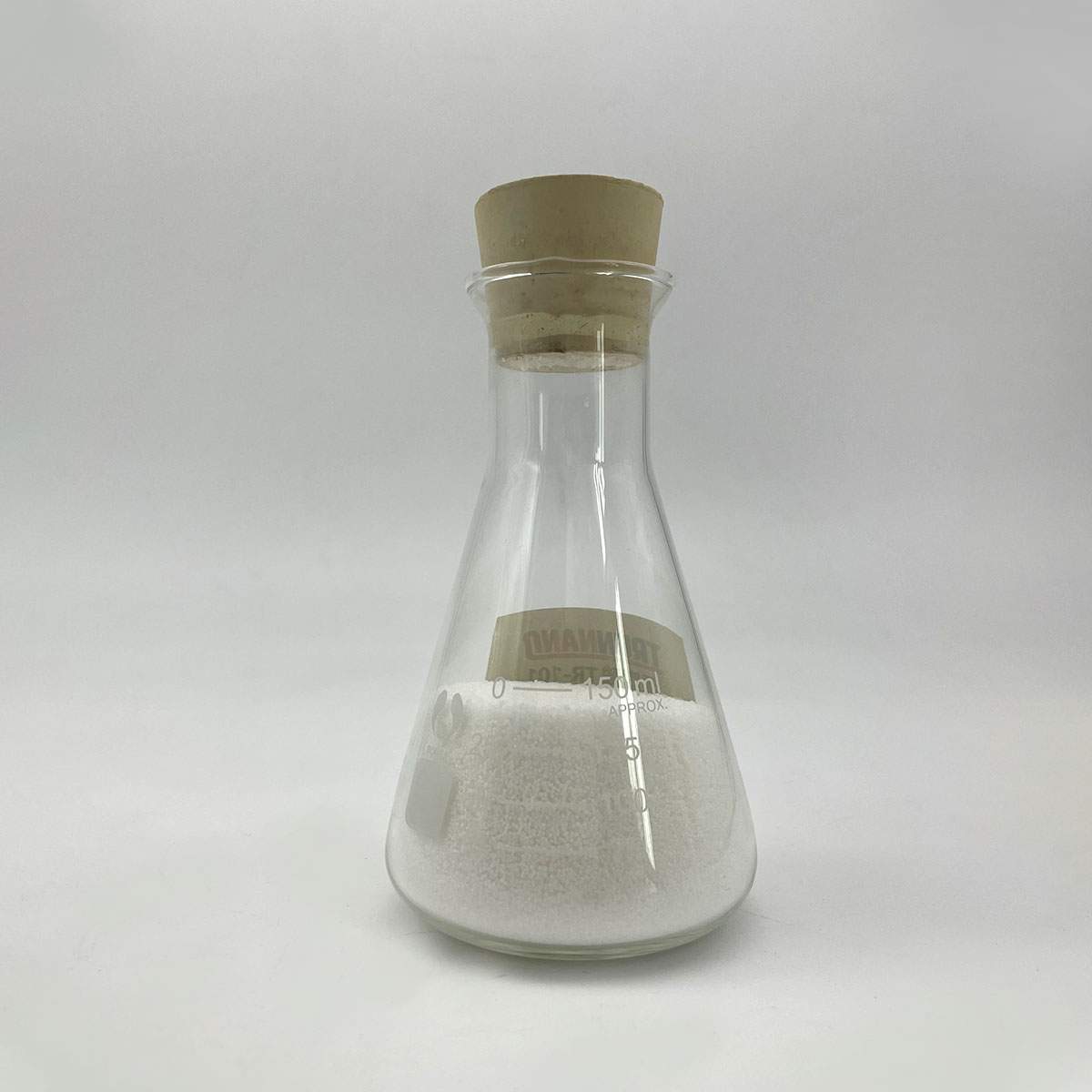

Spherical tantalum powder is a critical component in achieving efficient and accurate 3D printing. The spherical shape of the particles promotes better flowability during the printing process, reducing the formation of agglomerates and ensuring a uniform distribution of material. This results in a more consistent layer-by-layer build and fewer defects, leading to improved mechanical properties in the final part.

The spherical shape also aids in minimizing porosity, which is a common issue in metal 3D printing. As the particles fill the space between layers, their round form allows for better packing and reduces the chances of trapped gas or voids, thus enhancing the structural integrity of the printed object. This is particularly crucial for components where dimensional accuracy and strength are paramount.

One of the key advantages of using 99.9% spherical tantalum powder for 3D printing is its compatibility with various additive manufacturing techniques. It can be employed in processes such as selective laser melting (SLM), electron beam melting (EBM), and directed energy deposition (DED), allowing for the creation of intricate geometries and complex parts that would be challenging or impossible to produce using traditional methods.

Moreover, the high-purity tantalum powder enables the production of components with enhanced chemical stability. Tantalum’s resistance to corrosion and wear makes it ideal for aerospace, medical, and nuclear industries, where components are subjected to harsh environments. By 3D printing directly from the purest form of tantalum powder, manufacturers can create custom parts tailored to withstand corrosive atmospheres or high-temperature conditions.

However, it is essential to note that 99.9% spherical tantalum powder can be relatively expensive compared to other metals due to its rarity and refining process. This may impact the cost-effectiveness of large-scale production, but for specialized applications, the benefits offered by its superior properties often outweigh the initial investment.

In conclusion, 99.9% spherical tantalum powder is a game-changer in the world of 3D metal printing. Its high purity, spherical shape, and compatibility with various AM techniques make it a valuable material for producing components with exceptional strength, corrosion resistance, and dimensional accuracy. As the technology continues to evolve, the use of such advanced powders will likely expand the boundaries of what is possible in the manufacturing landscape, pushing the envelope of innovation and performance.

(3D Printing Metal Powder 99.9% Spherical Element Tantalum Ta Powder Spherical Tantalum Powder)

FAQs of 3D Printing Metal Powder 99.9% Spherical Element Tantalum Ta Powder Spherical Tantalum Powder

Inquiry us