Overview of PVD decoration coating use popular size 99.5–99.999 high purity titanium plate

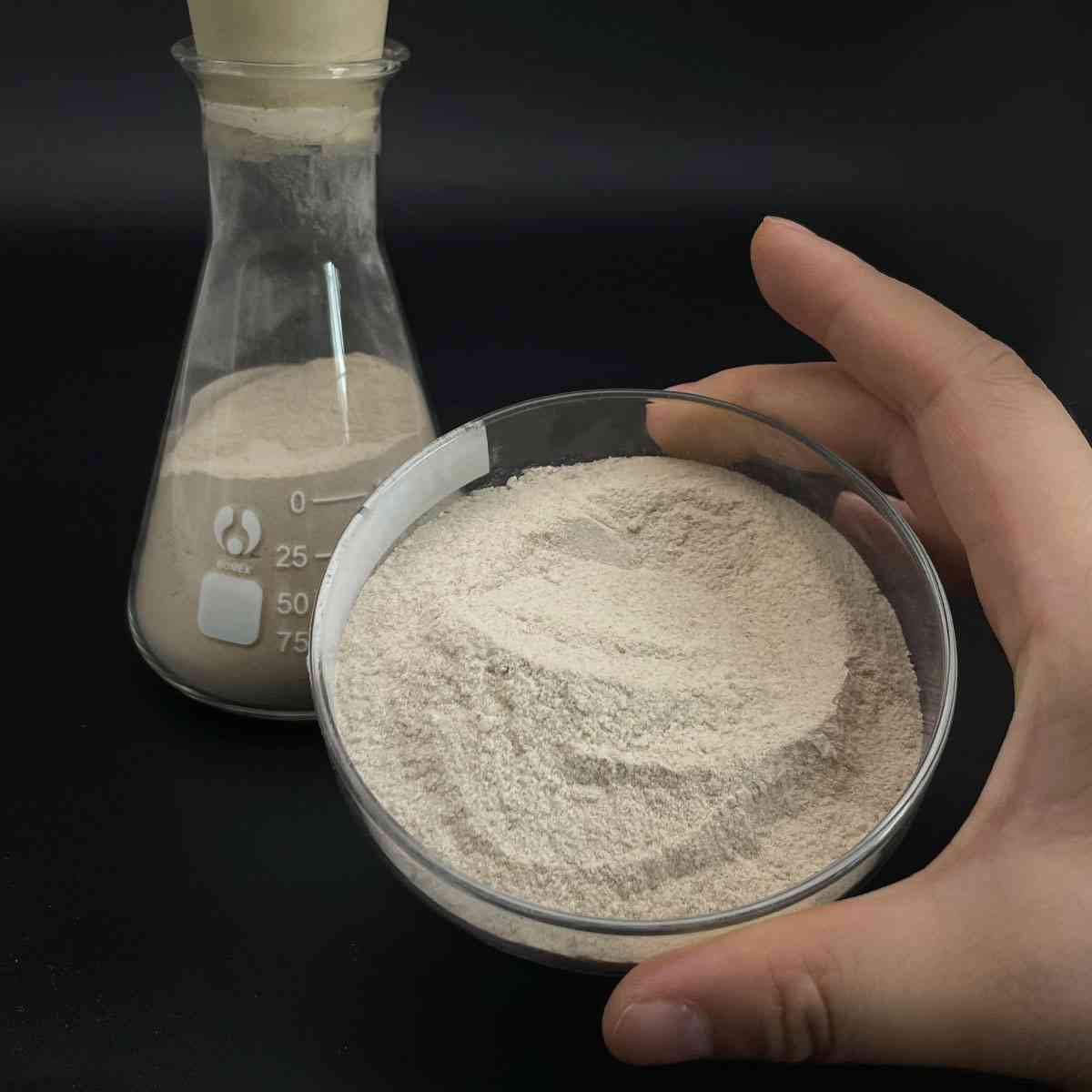

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of PVD decoration coating use popular size 99.5–99.999 high purity titanium plate

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(PVD decoration coating use popular size 99.5–99.999 high purity titanium plate)

Parameters of PVD decoration coating use popular size 99.5–99.999 high purity titanium plate

PVD (Physical Vapor Deposition) decoration coating is a sophisticated thin-film deposition technique widely employed to enhance the appearance and functionality of various substrates, including high purity titanium plates. Titanium, with its chemical symbol Ti and atomic number 22, is a popular choice due to its exceptional strength, lightweight, and biocompatibility. The purity level you mentioned, 99.5% to 99.999%, ensures an ultra-high quality material suitable for demanding applications.

In this context, a 99.5% to 99.999% pure titanium plate used for PVD coating typically has the following parameters:

1. **Chemical Composition**: The titanium content is virtually pure, with trace amounts of impurities like oxygen, nitrogen, and carbon being below 0.005%. This purity allows for a consistent and homogeneous coating, minimizing unwanted effects on the final product’s properties.

2. **Density**: High purity titanium has a density of around 4.5 grams per cubic centimeter, which contributes to its lightweight nature while maintaining structural integrity.

3. **Mechanical Properties**: The purity of the metal contributes to superior mechanical properties such as high strength-to-weight ratio, excellent corrosion resistance, and fatigue resistance, making it ideal for aerospace, medical, and industrial applications.

4. **Surface Finish**: The base plate surface must be prepared to achieve a smooth, clean, and atomically flat surface for optimal PVD adhesion. This may involve processes like polishing, etching, or grit blasting to attain a surface roughness (Ra) within the required specifications.

5. **Thickness**: Depending on the specific application, the titanium plate thickness ranges from a few micrometers to tens of micrometers. Thinner coatings are often used for aesthetics, while thicker layers are chosen for functional purposes like wear protection.

6. **PVD Process Parameters**: The PVD process itself involves heating the titanium target in a vacuum chamber, where it evaporates and forms a thin film on the substrate. Parameters like deposition pressure, temperature, and target power are carefully controlled to achieve the desired coating properties, such as hardness, adhesion, and color.

7. **Coating Materials**: PVD can deposit various metallic or ceramic coatings onto the titanium, such as gold, silver, ruthenium, or hard carbides, to provide decorative or functional finishes like mirror-like reflection, anti-corrosion, or wear resistance.

8. **Quality Control**: Rigorous quality control measures are in place to ensure the uniformity, thickness, and adherence of the coating across the entire plate. This includes inspection using techniques like X-ray diffraction, scanning electron microscopy, and profilometry.

In summary, PVD decoration coating of 99.5% to 99.999% pure titanium plates involves precise control over material preparation, deposition process parameters, and quality checks to deliver a high-quality, durable, and visually appealing finish. This advanced technique is essential for various industries where performance, aesthetics, and reliability are paramount.

(PVD decoration coating use popular size 99.5–99.999 high purity titanium plate)

FAQs of PVD decoration coating use popular size 99.5–99.999 high purity titanium plate

Inquiry us