Overview of Platinized / platinum coated niobium wire anode

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Platinized / platinum coated niobium wire anode

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

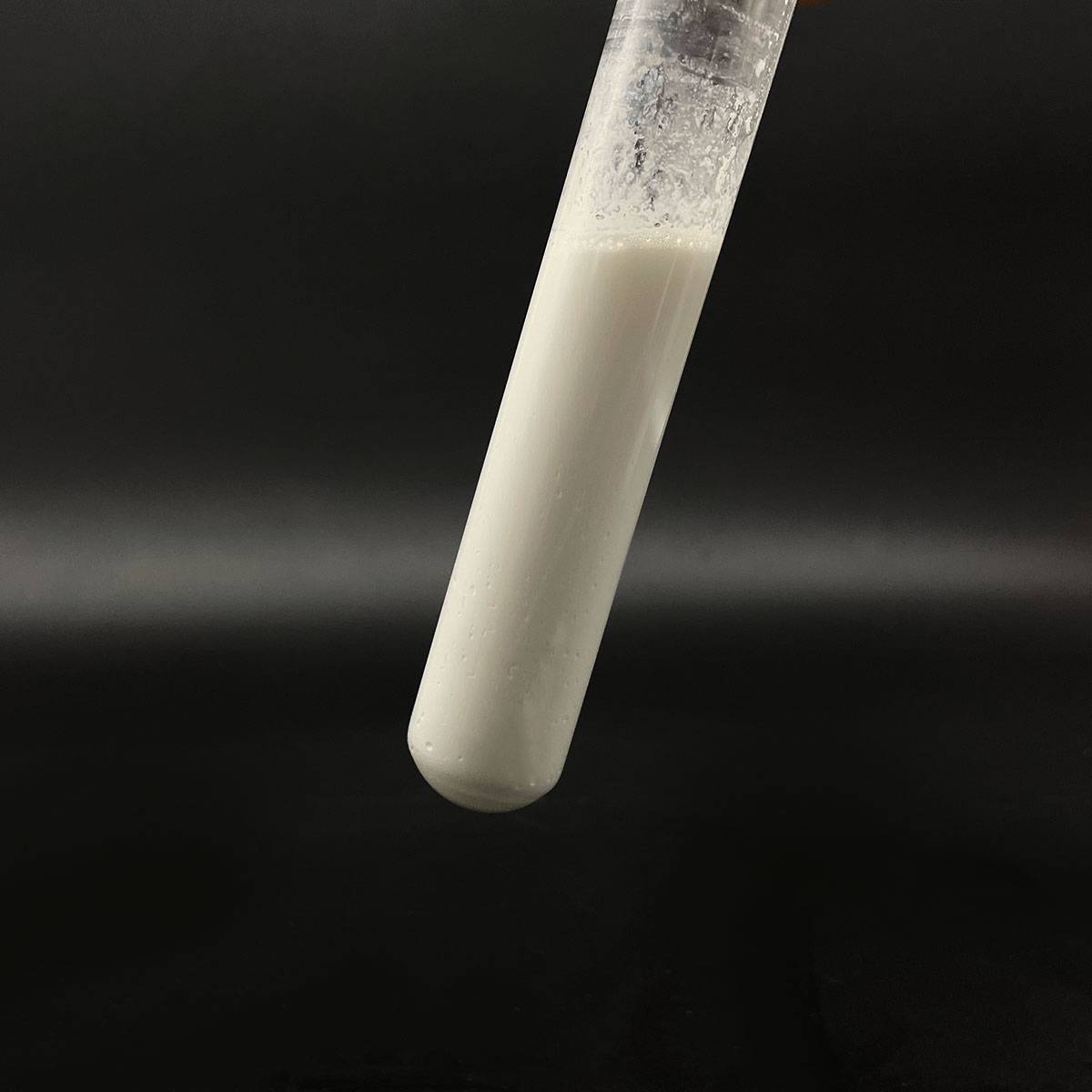

(Platinized / platinum coated niobium wire anode)

Parameters of Platinized / platinum coated niobium wire anode

Platinumized or platinum-coated niobium wire anodes are a specialized type of electrode commonly used in various industrial, scientific, and medical applications due to their unique properties. These anodes are characterized by the deposition of a thin layer of platinum onto high-purity niobium, which enhances their performance, durability, and efficiency.

The choice of niobium as the base material is primarily because of its low thermal expansion coefficient, high electrical conductivity, and excellent mechanical strength. Niobium has a low activation energy for hydrogen evolution, making it suitable for electrochemical processes like water splitting, where hydrogen production is desired. However, pure niobium can be prone to corrosion, which is where the platinum coating comes into play.

The platinum coating serves several purposes. Firstly, it provides a protective barrier against corrosion, extending the life of the anode. Platinum is known for its exceptional chemical stability and resistance to corrosion, which ensures that the underlying niobium remains intact during operation. This is particularly important in environments with aggressive chemicals or high temperatures, where corrosion rates can be accelerated.

Secondly, the platinum layer improves the overall catalytic activity of the anode. Platinum is a highly effective catalyst for many electrochemical reactions, including oxygen evolution and hydrogen evolution. By depositing a thin layer of platinum, the surface area is increased, enhancing the rate of these reactions without compromising the mechanical integrity of the anode.

The thickness of the platinum coating is a critical parameter that affects the performance of the anode. Thicker coatings can provide better protection against corrosion but may reduce the active surface area and thus the reaction rate. Conversely, thinner coatings offer higher catalytic activity but may require more frequent replacement due to wear. The ideal thickness depends on the specific application and the balance between durability and efficiency that is required.

In addition to thickness, other parameters to consider include the deposition method (e.g., physical vapor deposition, electroplating), purity of the platinum, and the uniformity of the coating. The quality control of these factors is essential to ensure consistent performance across multiple anodes.

Moreover, the diameter and flexibility of the platinum-coated niobium wire anode also play a role in determining its suitability for certain applications. A thinner wire is preferred for thin-film deposition or microelectronic devices, while thicker wires are more appropriate for larger-scale industrial processes.

In summary, platinumized or platinum-coated niobium wire anodes are advanced materials designed for efficient and durable electrochemical applications. Their combination of niobium’s inherent properties and the added catalytic power of platinum makes them ideal for use in areas such as fuel cells, water treatment, and semiconductor manufacturing. The precise selection and optimization of parameters like coating thickness, purity, and wire characteristics are crucial for achieving optimal performance in each specific application.

(Platinized / platinum coated niobium wire anode)

FAQs of Platinized / platinum coated niobium wire anode

Inquiry us