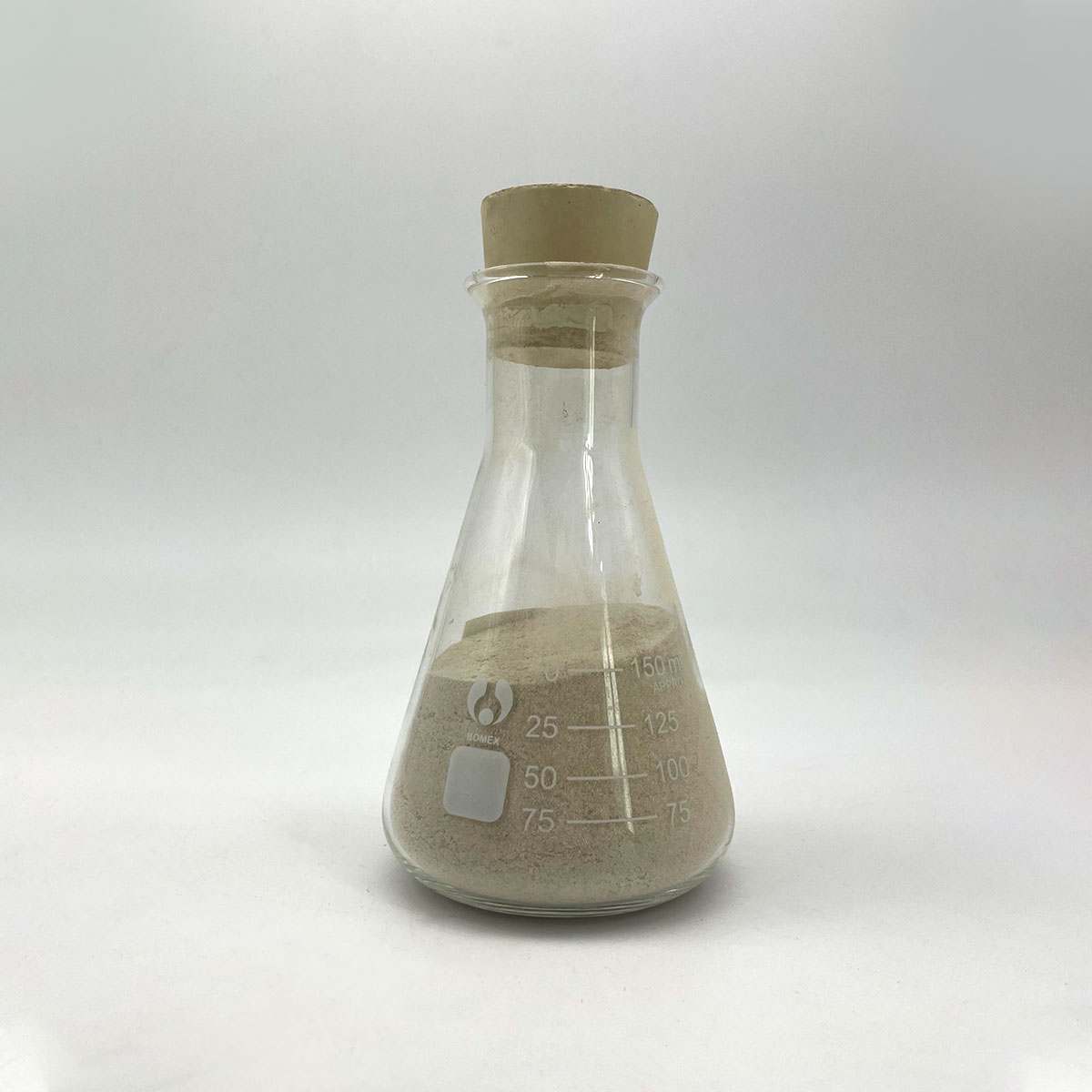

Overview of WC CO Tungsten carbide powder for HVOF and HVAF hardfacing metal alloy powder iridium hardfacing powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of WC CO Tungsten carbide powder for HVOF and HVAF hardfacing metal alloy powder iridium hardfacing powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(WC CO Tungsten carbide powder for HVOF and HVAF hardfacing metal alloy powder iridium hardfacing powder)

Parameters of WC CO Tungsten carbide powder for HVOF and HVAF hardfacing metal alloy powder iridium hardfacing powder

Welding Consumables: WC (Tungsten Carbide) Powder for HVOF and HVAF Hardfacing Applications

Tungsten carbide, abbreviated as WC, is a renowned material in the world of welding and hardfacing due to its exceptional properties, particularly in high-velocity oxy-fuel (HVOF) and high-voltage arc-fusion (HVAF) processes. These powders are used to deposit a wear-resistant, hard layer on metal alloys, enhancing their durability and extending the life of components in demanding industrial environments.

WC powder for hardfacing has several key parameters that make it suitable for these advanced welding techniques:

1. Particle Size Distribution: The powder’s particle size is crucial for achieving optimal flowability, weld pool control, and bond strength. A typical range for HVOF and HVAF applications is between 45 microns and 125 microns, with a narrow distribution for consistent results.

2. Purity: High-purity tungsten carbide (98% or above) ensures minimal impurities, which can affect the quality of the deposited layer and its mechanical properties. Impurities may cause porosity, brittleness, or reduced hardness.

3. Hardness: WC powders exhibit a high hardness, typically around 25-30 HRA (Rockwell hardness), making them ideal for creating a hardfacing layer that resists wear and tear. This hardness can be further increased by alloying with other elements like cobalt or iron.

4. Coating Adhesion: The WC powder should have good adhesion to the base metal, ensuring a strong bond between the substrate and the hardfacing layer. This is achieved through careful selection of particle shape and surface roughness, as well as proper preparation of the workpiece.

5. Thermal Conductivity: Tungsten carbide is an excellent conductor of heat, which is essential for efficient heat transfer during the HVOF or HVAF process. This helps maintain the integrity of the powder and the molten pool, resulting in a more uniform and defect-free deposit.

6. Melting Point: With a melting point of approximately 3422°C (6200°F), WC powder can withstand the intense temperatures generated during high-velocity welding processes without degradation.

7. Compatibility: It’s important that the WC powder is compatible with the base metal and the chosen welding gas mixture. Compatibility ensures proper fusion and minimizes spatter or porosity during the hardfacing process.

8. Environmental Considerations: WC powders are generally considered environmentally friendly, as they do not contain harmful substances. However, proper handling and disposal procedures should still be followed to minimize environmental impact.

9. Cost and Availability: While tungsten carbide is a premium material, its benefits in terms of durability and performance often outweigh the initial investment. The availability of WC powders varies depending on the supplier, but advancements in production methods have made it more accessible.

In conclusion, tungsten carbide powder for HVOF and HVAF hardfacing applications is characterized by its high hardness, purity, thermal conductivity, and compatibility with various metal alloys. By optimizing these parameters, engineers and technicians can achieve superior wear resistance and longevity in components subjected to harsh working conditions. As technology continues to evolve, so does the development of WC powders, ensuring better performance and efficiency in modern welding processes.

(WC CO Tungsten carbide powder for HVOF and HVAF hardfacing metal alloy powder iridium hardfacing powder)

FAQs of WC CO Tungsten carbide powder for HVOF and HVAF hardfacing metal alloy powder iridium hardfacing powder

Inquiry us