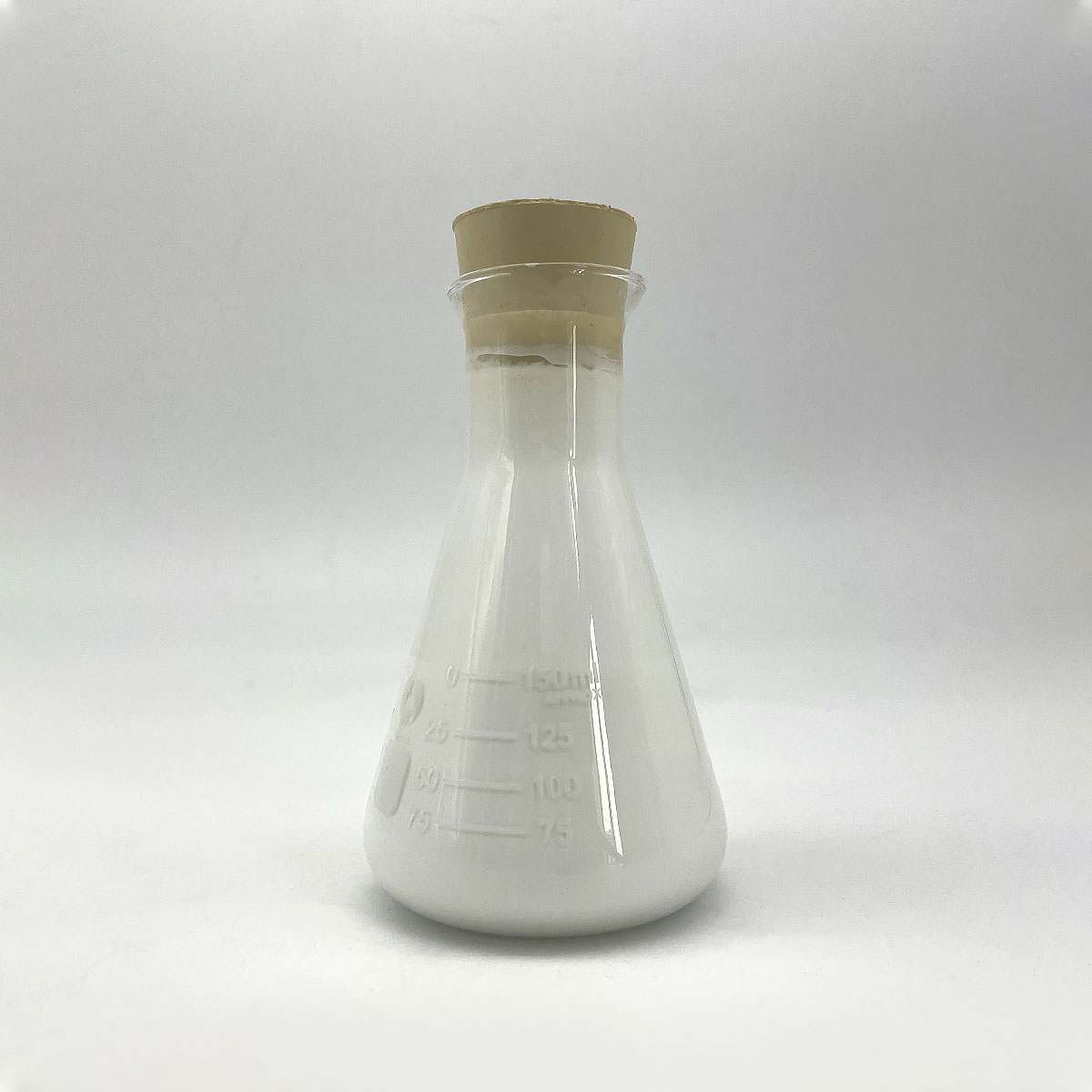

Overview of PTA Hardfacing Welding Laser Cladding HVOF Thermal Spray Tungsten Carbide Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of PTA Hardfacing Welding Laser Cladding HVOF Thermal Spray Tungsten Carbide Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(PTA Hardfacing Welding Laser Cladding HVOF Thermal Spray Tungsten Carbide Powder)

Parameters of PTA Hardfacing Welding Laser Cladding HVOF Thermal Spray Tungsten Carbide Powder

PTA (Polyetheretherketone) is a high-performance engineering thermoplastic with exceptional mechanical strength and wear resistance. It finds extensive applications in industries such as aerospace, automotive, and manufacturing due to its lightweight, dimensional stability, and chemical resistance. When it comes to hardfacing welding, laser cladding, and thermal spray tungsten carbide (WC) coatings, optimizing the process parameters is crucial for achieving desired results.

Laser cladding involves depositing a layer of tungsten carbide powder onto the PTA substrate using a high-power laser. This method enhances the surface properties by providing a hard, wear-resistant coating. The following are some critical parameters involved in this process:

1. **Laser Power**: The power output significantly affects the melting rate and the depth of the deposited layer. Higher power leads to faster melting and quicker deposition, but may result in a less uniform coating. A balance must be found to ensure adequate fusion without overheating the base material.

2. **Laser Beam Diameter**: The beam width determines the heat input and the size of the melt pool. A smaller diameter provides better control over the coating’s quality but may require longer processing times.

3. **Pulse Frequency**: The number of laser pulses per unit time influences the cooling rate and the microstructure of the deposited layer. Faster cooling can produce a finer grain structure, improving wear resistance.

4. **Powder Characteristics**: The particle size, shape, and composition of the tungsten carbide powder play a significant role. Fine particles provide better flowability and coating density, while larger particles can result in a more rugged surface finish. A suitable blend of particle sizes ensures good bonding with the substrate.

5. **Substrate Preparation**: Proper cleaning and surface roughening of the PTA substrate are essential for adhesion between the base material and the WC coating. Techniques like sandblasting or grit blasting can enhance bonding.

6. **Cladding Speed**: The speed at which the laser moves across the substrate affects the layer thickness and the thermal history. Slower speeds allow for better heat dissipation, reducing thermal stress and minimizing porosity.

7. **Coolant and Protective Gas**: The use of a coolant and protective gas (e.g., argon or nitrogen) is vital to minimize thermal distortion and protect the substrate from excessive heating. The choice and flow rate should be optimized.

8. **Process Control**: Advanced process control systems monitor and adjust parameters in real-time to maintain consistency and minimize defects.

9. **Post-processing**: After cladding, post-processing steps like grinding, polishing, or hardening may be necessary to achieve the desired surface finish and hardness.

In summary, PTA hardfacing welding, laser cladding, and thermal spray tungsten carbide applications involve a series of interrelated parameters that need to be carefully controlled to optimize the coating’s performance on the PTA substrate. By adjusting these factors, engineers can tailor the coating to meet specific application requirements, extending the service life and enhancing the functionality of PTA components.

(PTA Hardfacing Welding Laser Cladding HVOF Thermal Spray Tungsten Carbide Powder)

FAQs of PTA Hardfacing Welding Laser Cladding HVOF Thermal Spray Tungsten Carbide Powder

Inquiry us