Overview of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

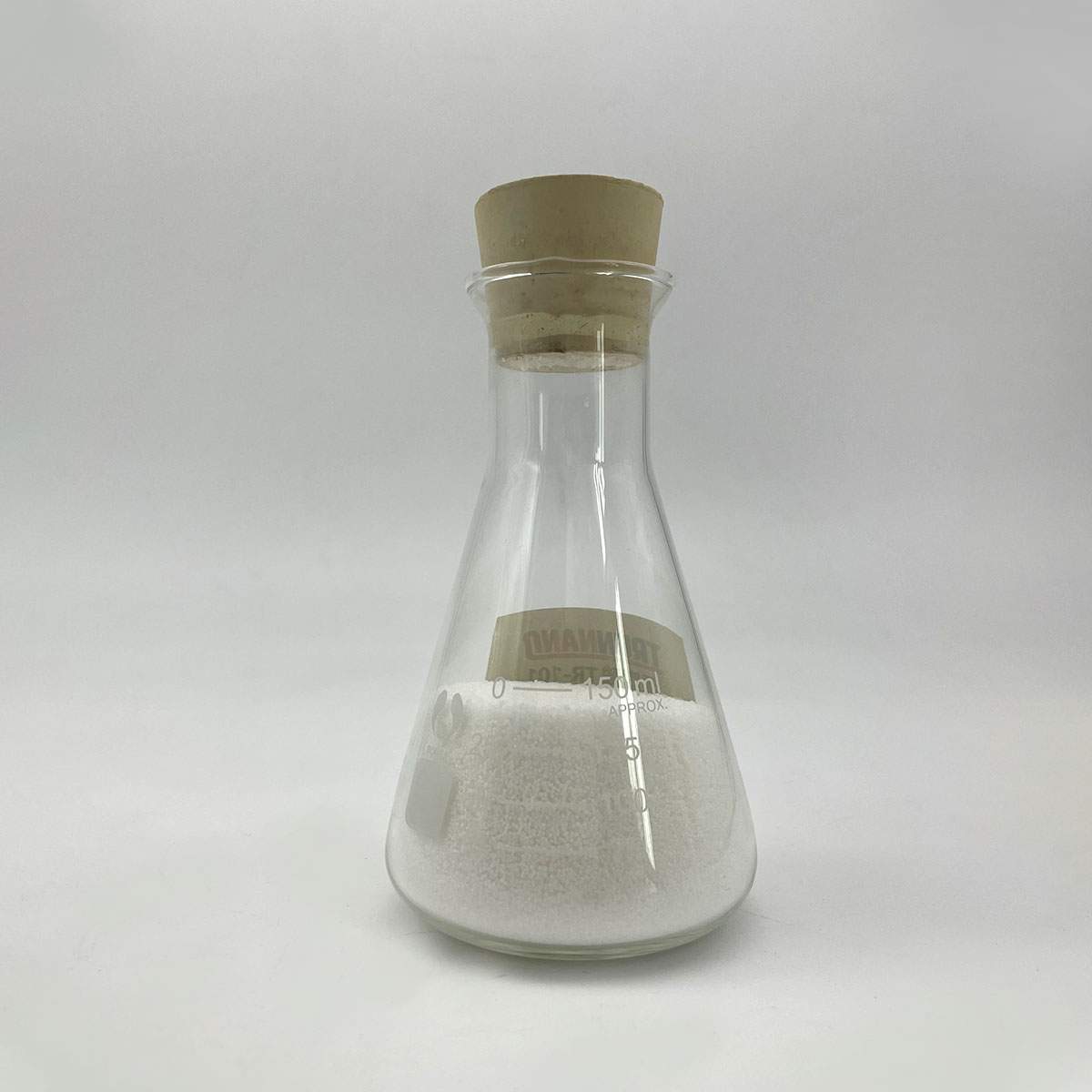

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes)

Parameters of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

Title: Comprehensive Overview of Wolfram Carbide Cast Tungsten Carbide Welding Wire and Electrodes

Tungsten carbide, a high-performance material known for its exceptional hardness, wear resistance, and thermal stability, is widely used in various industrial applications, including welding. Wolfram carbide cast tungsten carbide welding wire and electrodes are specifically designed to provide efficient and durable welding solutions. Here’s an in-depth look at the key parameters of these materials without specific formatting:

1. Composition:

Wolfram carbide cast tungsten carbide welding wire typically consists of tungsten (WC), carbon (C), and sometimes additional elements like cobalt (Co), molybdenum (Mo), and rhenium (Re) to enhance properties like toughness, wear resistance, and creep strength. The exact composition may vary depending on the intended application and the manufacturer.

2. Grades:

There are different grades of tungsten carbide welding wires available, such as WC75/25 (75% tungsten, 25% carbon), WC80/20, or WC90/10, which denote the tungsten to carbon ratio. Higher tungsten content results in higher melting points and harder welds, while lower carbon content provides better machinability and arc stability.

3. Size and Shape:

Welding wires come in various sizes, ranging from 0.8mm to 3.2mm in diameter, suitable for different welding processes like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), or PTA (Plasma Transferred Arc). The wires can be round, flat, or hollow core, depending on the application requirements.

4. Iron Powder Welding Rods:

Iron powder tungsten carbide rods, often used for submerged arc welding (SMAW), contain tungsten carbide particles dispersed within an iron matrix. These rods offer excellent heat transfer, low dilution, and improved mechanical properties in the weld. Their dimensions can vary, with typical diameters ranging from 1.6mm to 3.2mm.

5. Copper-Nickel Welding Electrodes:

Copper-nickel tungsten carbide electrodes, also known as cupola brazing rods, are used for brazing and surfacing applications. They consist of tungsten carbide particles mixed with a copper-nickel alloy. The electrode size varies, usually between 3mm and 12mm in diameter, with a length of 300mm to 600mm.

6. Properties:

– High melting point: Tungsten carbide welding materials have a high resistance to heat, enabling them to withstand intense temperatures during welding.

– Excellent wear resistance: The material’s hardness and abrasion resistance prevent excessive wear on tools and equipment.

– Low thermal conductivity: This helps retain heat in the welding zone, improving the quality of the weld.

– Good chemical inertness: Tungsten carbide is resistant to corrosion and oxidation, making it suitable for various environments.

7. Welding Processes:

These materials are compatible with various welding techniques, including MIG, TIG, SAW, and brazing, depending on the wire or rod type.

In conclusion, Wolfram carbide cast tungsten carbide welding wire and electrodes are designed to deliver superior performance in demanding applications due to their unique combination of properties. Their tailored compositions and diverse forms cater to the needs of various industries, ensuring reliable and efficient welding outcomes. Understanding these parameters is crucial for selecting the right material for a specific welding project.

(Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes)

FAQs of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

Inquiry us