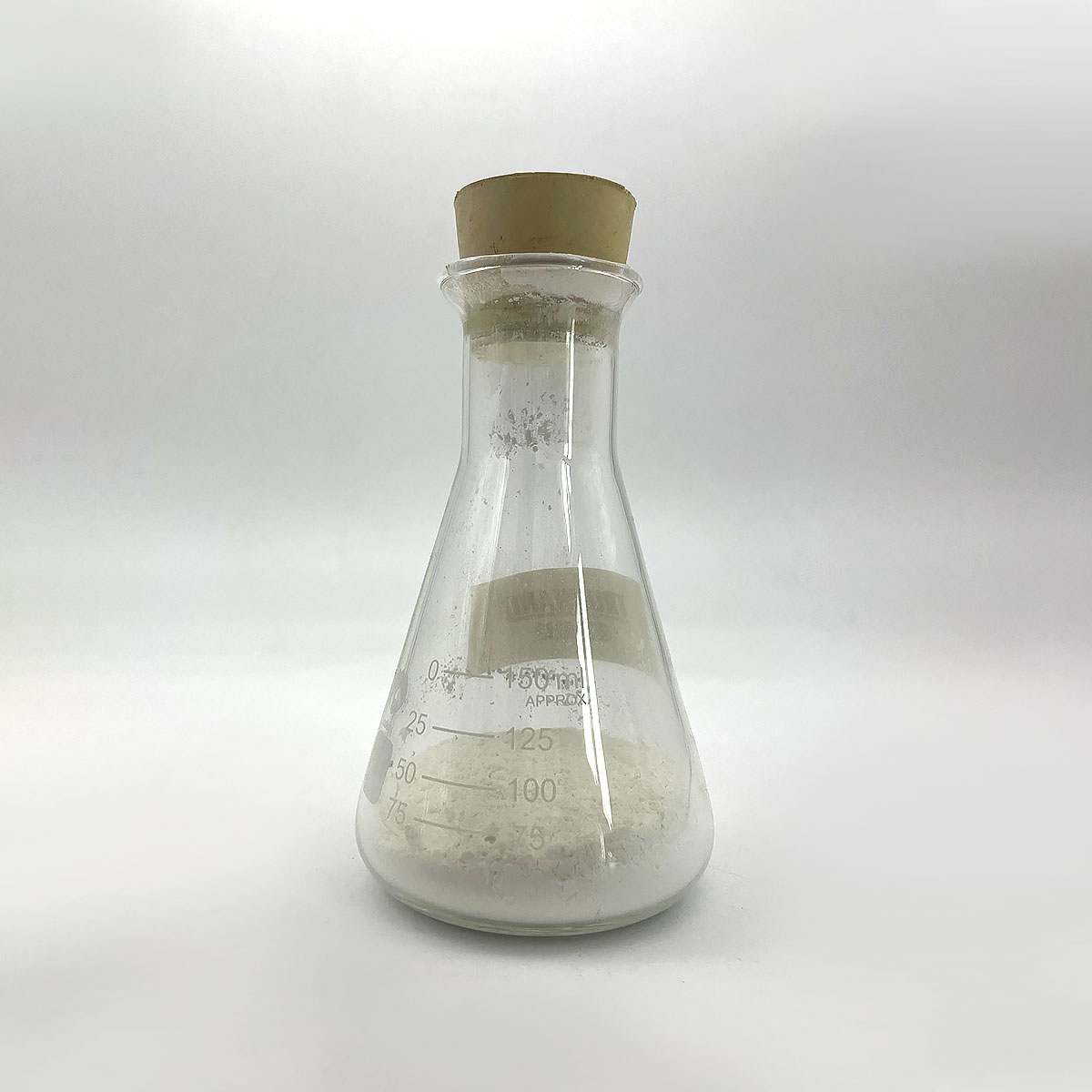

Overview of Tungsten Carbide Powder/WC powder for casting

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Tungsten Carbide Powder/WC powder for casting

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Tungsten Carbide Powder/WC powder for casting)

Parameters of Tungsten Carbide Powder/WC powder for casting

Tungsten Carbide Powder, also known as WC powder, is a high-performance material that finds extensive applications in various industries due to its exceptional properties, including extreme hardness, wear resistance, and thermal stability. This particular form of the material is primarily used in metal casting processes, where it serves as a key component for producing tungsten carbide-based components such as cutting tools, wear-resistant coatings, and industrial machinery parts.

The casting process involving tungsten carbide powder typically involves a powder metallurgy technique, which encompasses several critical parameters to ensure optimal results:

1. Particle Size Distribution: WC powder is available in different particle sizes, ranging from sub-micron to coarse. The choice depends on the desired mechanical properties and the ability to achieve uniform distribution during the casting process. Fine particles promote better flowability and packing density, while larger ones may offer better strength and toughness.

2. Purity: A high purity level (usually above 95%) is essential for achieving the desired performance. Impurities can affect the hardness, wear resistance, and overall quality of the final product. Therefore, rigorous purification techniques are employed to minimize contamination.

3. Sinterability: WC powder’s sinterability refers to its ability to bond together when subjected to heat and pressure. It is influenced by factors such as the binder content, particle shape, and the sintering temperature. The right balance is crucial to obtain a strong, dense structure with minimal porosity.

4. Binder Content: WC powders are often mixed with binders like cobalt, iron, or titanium to facilitate consolidation during the casting process. The binder’s type, amount, and composition significantly impact the green strength, sintering behavior, and the final microstructure of the cast part.

5. Green Compaction: The compacting process, where the powder is pressed into a pre-defined shape, influences the density and porosity of the mold. High compaction pressures and proper die design are necessary to achieve a dense green body, which translates to better mechanical properties after sintering.

6. Sintering Parameters: Sintering temperatures, holding times, and heating rates play a vital role in the densification and grain growth of the WC matrix. The goal is to obtain a fine-grained structure that enhances hardness and wear resistance. The choice of atmosphere (air, vacuum, or inert gas) can also impact the final properties.

7. Post-Sintering Treatment: After sintering, the part may undergo additional treatments like heat treatment or surface modification to optimize its properties further. This could involve tempering to increase toughness or coating with other materials for improved wear resistance.

In conclusion, tungsten carbide powder for casting is a versatile material that demands careful consideration of various parameters to produce high-quality components. By optimizing these aspects, manufacturers can harness the full potential of WC and create products that excel in demanding environments where wear, hardness, and durability are paramount.

(Tungsten Carbide Powder/WC powder for casting)

FAQs of Tungsten Carbide Powder/WC powder for casting

Inquiry us