Overview of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

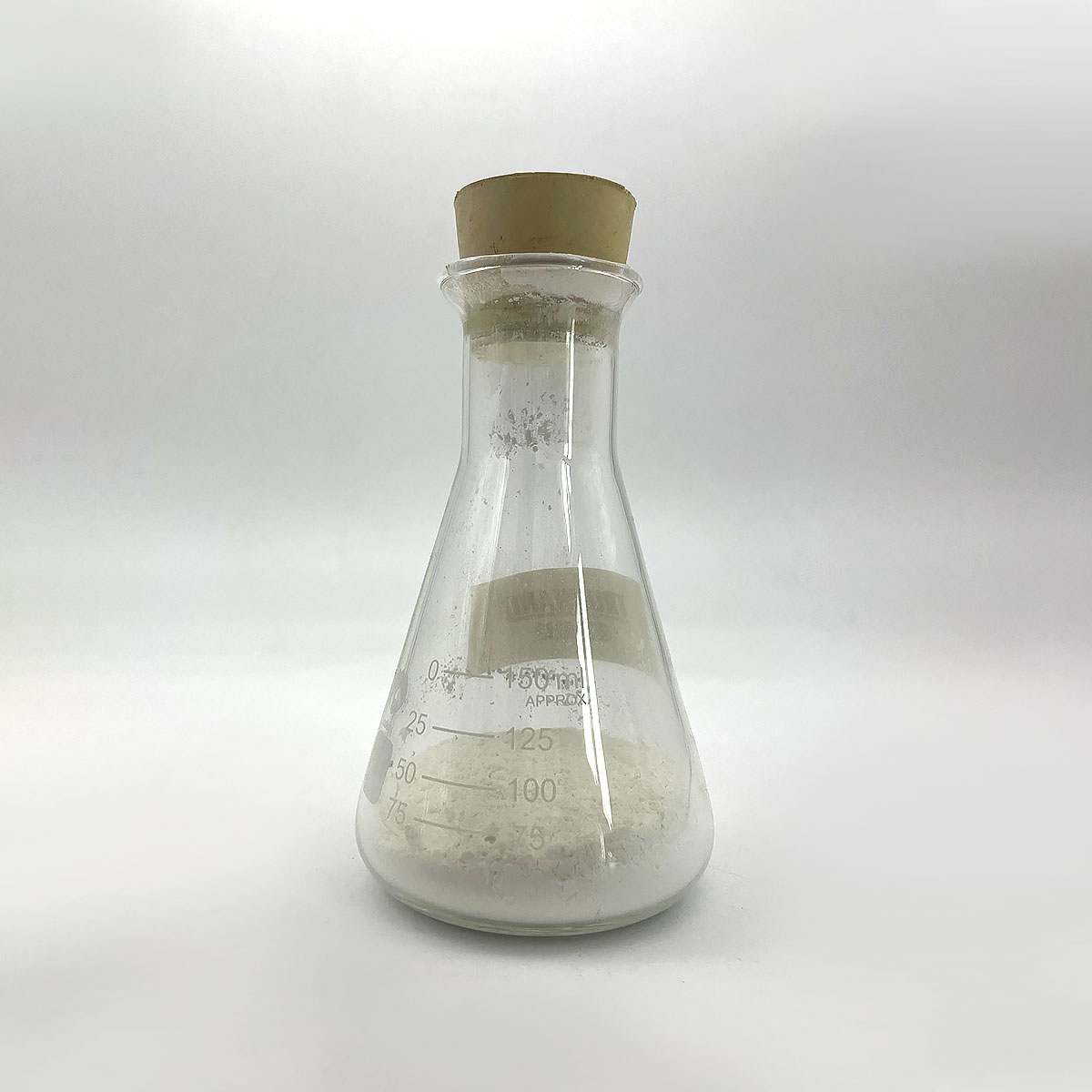

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes)

Parameters of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

Wolfram Carbide Cast Tungsten Carbide Welding Wire and Iron Powder Welding Rods: A Comprehensive Overview

Tungsten carbide, known for its exceptional hardness, wear resistance, and high-temperature stability, is a popular choice in welding applications. The combination of tungsten carbide with other materials like iron powder or copper-nickel alloys creates specialized welding electrodes that offer unique advantages in various industrial sectors. This article delves into the key parameters and characteristics of Wolfram Carbide cast tungsten carbide welding wire and iron powder welding rods, as well as copper-nickel welding electrodes.

1. Tungsten Carbide Composition:

Wolfram carbide welding wires typically consist of tungsten (WC) as the primary component, which ranges from 90% to 95%. The remaining percentage consists of carbon (C), often in the form of graphite, to enhance the material’s hardness and wear resistance. Some grades may also include small amounts of cobalt (Co) or molybdenum (Mo) to improve machinability and weldability.

2. Cast Process:

Cast tungsten carbide welding wire is produced by melting tungsten carbide particles and then casting them into a desired shape, such as a wire. This process allows for a uniform distribution of elements within the material, ensuring consistent performance across the entire electrode.

3. Iron Powder Welding Rods:

Iron powder welding rods, when combined with tungsten carbide, provide an excellent combination of strength and ductility. The iron powder acts as a filler material, enhancing the weld pool’s flowability and reducing porosity. These rods usually contain around 70-80% tungsten carbide and 20-30% iron powder. They are suitable for welding hard-to-weld materials like stainless steel, high-strength steel, and even some non-ferrous metals.

4. Copper-Nickel Welding Electrodes:

Copper-nickel welding electrodes, often referred to as cupronickel electrodes, are made by blending tungsten carbide with copper and nickel. This mixture provides excellent arc stability, low spatter, and good wetting properties. The copper content helps maintain a higher electrical conductivity, while nickel improves corrosion resistance. These electrodes are ideal for applications involving marine environments, chemical processing, and high-temperature service.

5. Parameters:

– Diameter: Welding wires and rods come in various sizes, ranging from 0.5mm to 4.0mm, depending on the specific application and required penetration.

– Hardness: The hardness of tungsten carbide can vary, but it’s typically around HRC 80-92, making it suitable for demanding welding tasks.

– Melting Point: Tungsten carbide has a high melting point (3692°C), which ensures stable welding even under extreme conditions.

– Arc Characteristics: The electrode’s composition affects the arc’s stability, arc length, and energy output, with tungsten carbide providing a strong, stable arc.

– Weld Pool Properties: The addition of iron powder or copper-nickel enhances the weld pool’s ability to fill and produce a strong bond.

In conclusion, Wolfram carbide cast tungsten carbide welding wire and iron powder welding rods, along with copper-nickel electrodes, offer exceptional performance in demanding welding applications. Their unique compositions, combined with the casting process, result in robust and efficient welding solutions for industries requiring high strength, wear resistance, and corrosion resistance. Understanding these parameters is crucial for selecting the right welding material for specific projects and ensuring optimal welding outcomes.

(Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes)

FAQs of Wolfram Carbide cast Tungsten carbide welding wire iron powder welding rods copper nickel welding electrodes

Inquiry us