Overview of High-quality Ronsco Ph Metal Nickel Chromium Molybdenum 625 Nickel-based Alloy W.nr 2.4375 Nickel Alloy Plate/Sheet

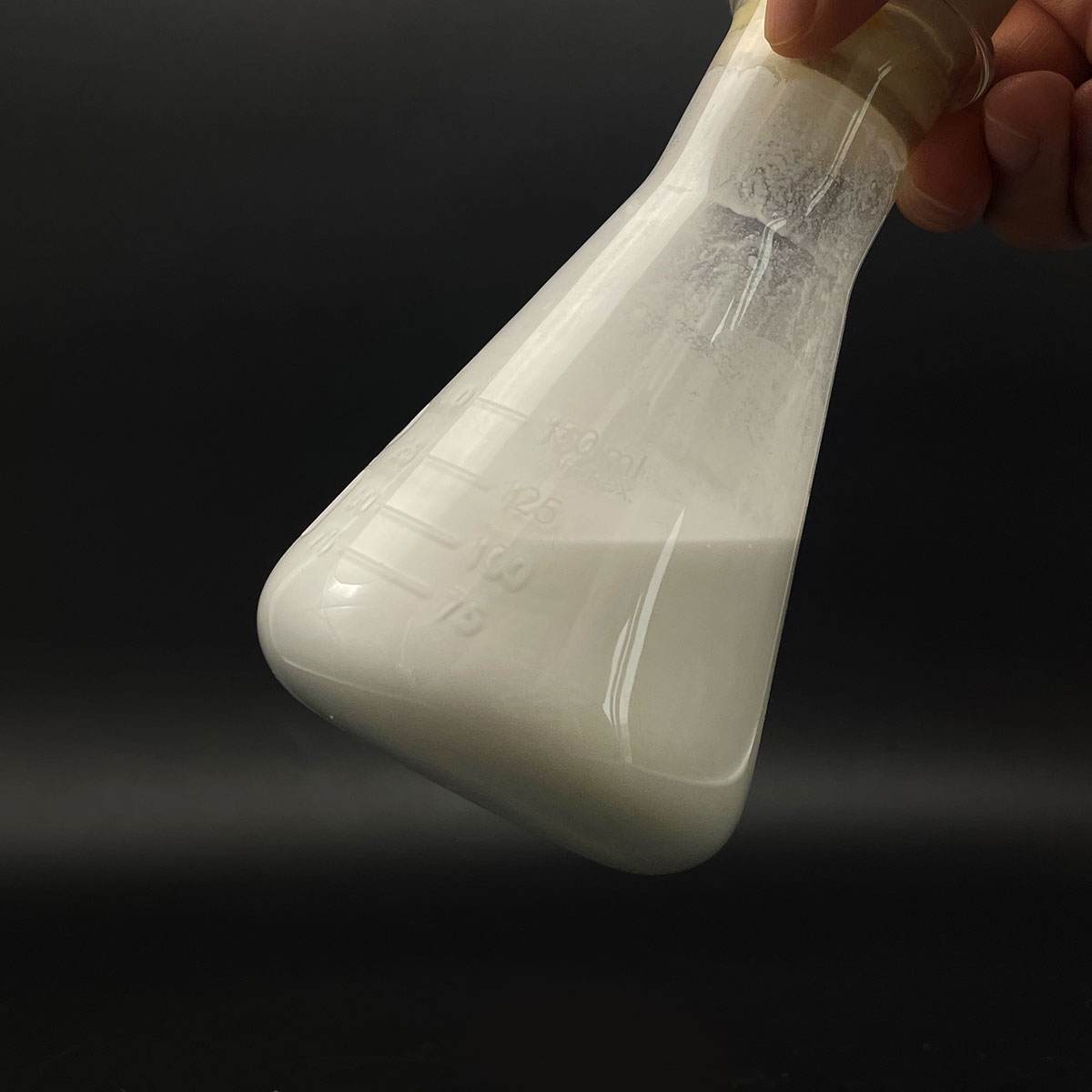

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High-quality Ronsco Ph Metal Nickel Chromium Molybdenum 625 Nickel-based Alloy W.nr 2.4375 Nickel Alloy Plate/Sheet

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High-quality Ronsco Ph Metal Nickel Chromium Molybdenum 625 Nickel-based Alloy W.nr 2.4375 Nickel Alloy Plate/Sheet)

Parameters of High-quality Ronsco Ph Metal Nickel Chromium Molybdenum 625 Nickel-based Alloy W.nr 2.4375 Nickel Alloy Plate/Sheet

Ronscos’ high-quality Ph Metal Nickel Chromium Molybdenum 625 (NiCrMo 625) Nickel-based alloy, also known as Wrought Nickel-Chromium-Molybdenum 2.4375 or UNS N0625, is a premium engineering material that boasts exceptional performance in demanding environments. This versatile alloy is specifically designed to withstand extreme temperatures, corrosion resistance, and mechanical stress, making it an indispensable choice for various industrial applications.

Nickel-Chromium-Molybdenum 625 is characterized by its superior combination of properties. It consists primarily of around 55% nickel, 22% chromium, 12% molybdenum, and trace amounts of other elements like iron, carbon, and silicon. The presence of these elements endows the alloy with remarkable features such as:

1. High Temperature Stability: NiCrMo 625 maintains its strength and ductility up to 1300°C (2372°F), which is crucial for applications involving continuous exposure to elevated temperatures.

2. Corrosion Resistance: This alloy exhibits excellent resistance to a wide range of aggressive chemicals, including hydrochloric acid, sulfuric acid, and seawater, making it ideal for use in marine, chemical processing, and petrochemical industries.

3. Creep Resistance: It has low creep rates even under prolonged high stress conditions, ensuring structural integrity over extended periods.

4. Oxidation Resistance: NiCrMo 625 forms a protective oxide layer on its surface, preventing further corrosion and extending its service life.

5. Pitting and Stress Corrosion cracking Resistance: Its composition helps to mitigate the risk of pitting and stress corrosion cracking, which are common failure modes in certain chloride-rich environments.

6. Weldability: Despite its high strength, NiCrMo 625 is relatively easy to weld, allowing for efficient fabrication without compromising integrity.

7. Mechanical Properties: The alloy offers a balance between strength, toughness, and ductility, making it suitable for both pressure vessels and structural components.

Applications of NiCrMo 625 include:

– Heat Exchangers: In power generation, petrochemicals, and aerospace industries, where high temperature and corrosion resistance are critical.

– Pumps and Valves: These components often operate in harsh environments, where NiCrMo 625’s durability is essential.

– Chemical Process Equipment: The alloy is used in tanks, reactors, and pipelines for handling corrosive chemicals.

– Offshore and Subsea Engineering: It is employed in deep-sea exploration and drilling equipment due to its resistance to seawater and corrosion.

– Aerospace: NiCrMo 625 finds application in high-temperature engine components, such as nozzles and compressor blades.

In summary, Ronscos’ Ph Metal Nickel Chromium Molybdenum 625 Nickel-based alloy is a top-of-the-line material, delivering exceptional performance in challenging conditions. Its unique combination of properties makes it an indispensable material for engineers and manufacturers seeking reliable, long-lasting solutions in various industries.

(High-quality Ronsco Ph Metal Nickel Chromium Molybdenum 625 Nickel-based Alloy W.nr 2.4375 Nickel Alloy Plate/Sheet)

FAQs of High-quality Ronsco Ph Metal Nickel Chromium Molybdenum 625 Nickel-based Alloy W.nr 2.4375 Nickel Alloy Plate/Sheet

Inquiry us