Overview of 3d Metal Printing Cobalt Chromium Molybdenum Powder Cocrmo Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 3d Metal Printing Cobalt Chromium Molybdenum Powder Cocrmo Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

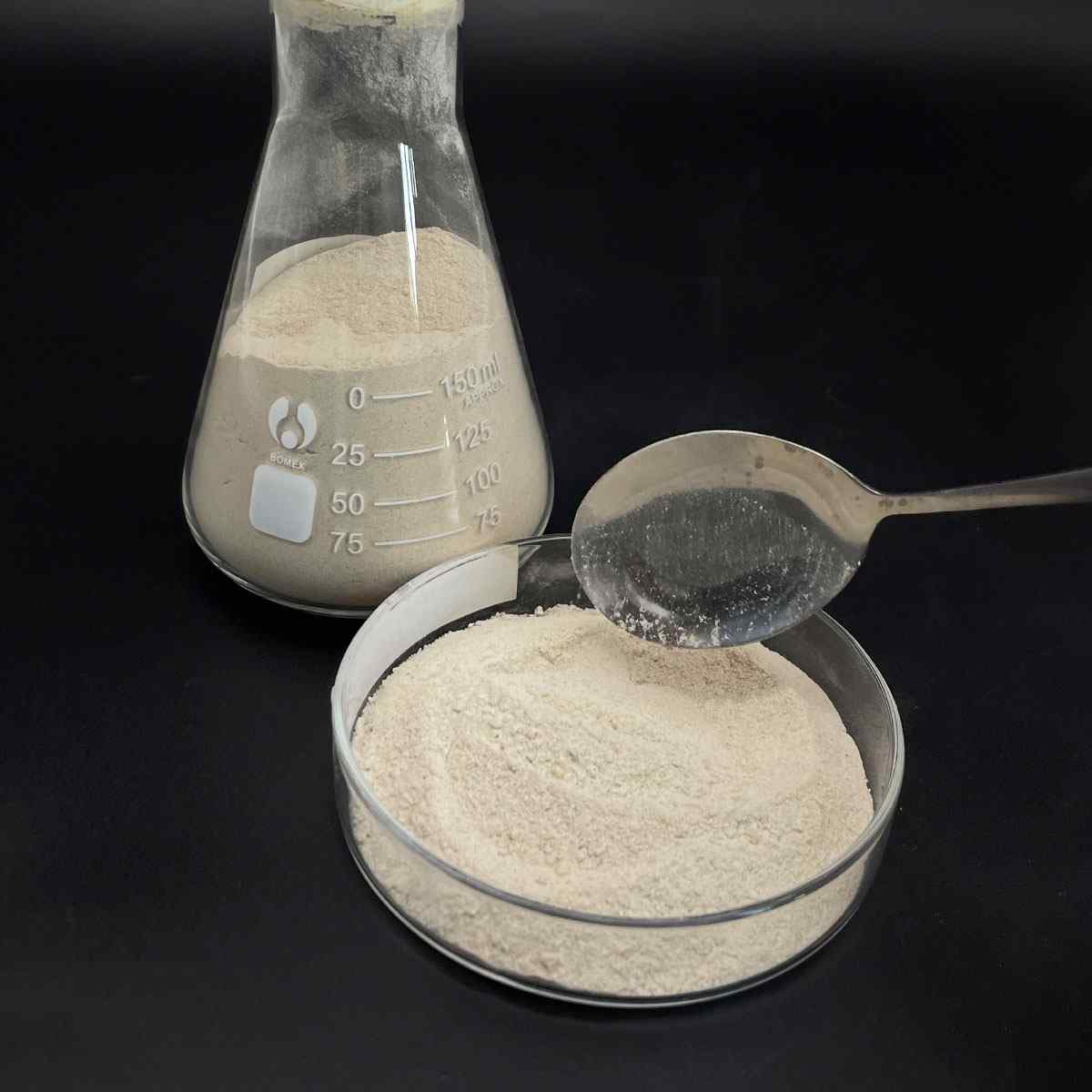

(3d Metal Printing Cobalt Chromium Molybdenum Powder Cocrmo Powder)

Parameters of 3d Metal Printing Cobalt Chromium Molybdenum Powder Cocrmo Powder

Three-dimensional metal printing, particularly using cobalt-chromium-molybdenum (CoCrMo) powder, is a cutting-edge manufacturing technique that has revolutionized the way we create intricate and durable components in various industries. CoCrMo powder, a blend of cobalt, chromium, and molybdenum, offers unique properties that make it an ideal choice for this process.

Cobalt-Chromium-Molybdenum (CoCrMo) Powder Parameters:

1. Composition: The primary constituents of CoCrMo powder are cobalt (Co), which provides strength and ductility, chromium (Cr), responsible for wear resistance and corrosion protection, and molybdenum (Mo), enhancing high-temperature stability and wear resistance. The typical ratio can vary from 60-70% cobalt, 20-25% chromium, and 5-15% molybdenum, although custom compositions can be tailored to specific application requirements.

2. Particle Size: The particle size distribution is a crucial factor affecting the printability and mechanical properties of the final product. CoCrMo powders typically have a narrow size range, with particles ranging from 45 microns to 100 microns or even finer. This controlled particle size ensures better flow during the printing process and improved part density.

3. Sinterability: CoCrMo powders exhibit excellent sinterability, meaning they can bond well when subjected to heat during the consolidation process. This allows for the creation of strong, dense structures with minimal porosity, essential for load-bearing applications.

4. Melting Point: With a melting point around 2,300°C, CoCrMo powder can withstand high temperatures without degrading, making it suitable for applications where thermal stability is critical, such as aerospace, automotive, and biomedical sectors.

5. Microstructure: The printed CoCrMo parts exhibit a fine-grained microstructure, which contributes to its superior strength and toughness. This microstructure can be controlled by adjusting the printing parameters, ensuring optimal performance in demanding environments.

6. Processing Techniques: Commonly used for 3D metal printing are Laser Metal Deposition (LMD), Electron Beam Melting (EBM), and Directed Energy Deposition (DED). These methods allow for layer-by-layer deposition of the CoCrMo powder, creating complex geometries and intricate features.

7. Post-Processing: After printing, the part undergoes heat treatment, such as annealing or sintering, to consolidate the powder and refine the microstructure. This step ensures dimensional accuracy, improved mechanical properties, and enhanced surface finish.

8. Applications: CoCrMo 3D printed components find applications in orthopedic implants, dental prosthetics, turbine blades, engine components, and aerospace structures due to their wear-resistant, corrosion-resistant, and biocompatible nature.

In conclusion, CoCrMo powder’s unique combination of properties makes it a popular choice for 3D metal printing. By carefully controlling the composition, particle size, and processing techniques, manufacturers can create high-quality, customized parts with exceptional performance in demanding environments. As technology advances, the potential for CoCrMo in 3D printing continues to expand, unlocking new possibilities across various industries.

(3d Metal Printing Cobalt Chromium Molybdenum Powder Cocrmo Powder)

FAQs of 3d Metal Printing Cobalt Chromium Molybdenum Powder Cocrmo Powder

Inquiry us