Overview of Nano molybdenum powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Nano molybdenum powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

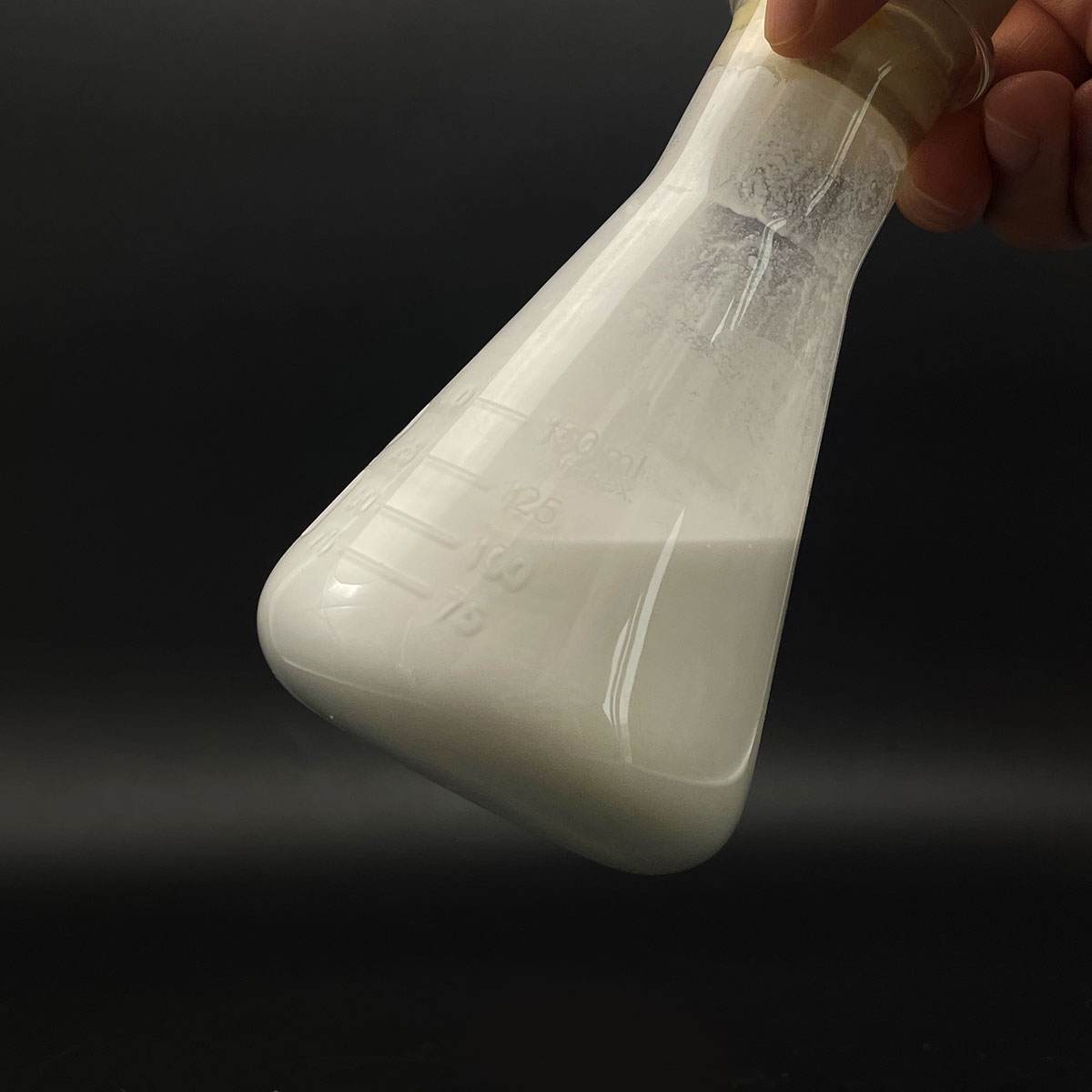

(Nano molybdenum powder )

Parameters of Nano molybdenum powder

Molybdenum, a chemical element with the symbol Mo and atomic number 42, is a hard, silvery-gray metal known for its exceptional strength, durability, and resistance to corrosion. Nanomolybdenum powder, specifically, refers to the extremely fine particles of molybdenum that have been reduced to dimensions on the nanoscale – typically ranging from 1 to 100 nanometers in size.

The unique properties of nano molybdenum powder stem from its extraordinary surface area-to-volume ratio, which increases significantly as it transitions to the nanometer scale. This results in enhanced mechanical, thermal, and electrical properties compared to its bulk form. Some key parameters of nano molybdenum powder include:

1. Grain Size: The particle size distribution is crucial in determining the material’s properties. A narrow size distribution ensures better consistency and performance. High-quality nano molybdenum powders often exhibit a uniform particle size, leading to improved dispersion and processing characteristics.

2. Purity: The purity of the nano molybdenum powder affects its chemical stability and reactivity. High-purity nano molybdenum typically contains less than 1% impurities, ensuring minimal contamination during applications.

3. Surface Area: The high surface area of nano molybdenum allows for increased interaction with other materials, enhancing its catalytic and adsorption capabilities. It also contributes to better mechanical bonding when used in composite materials.

4. Strength and Hardness: At the nanoscale, molybdenum exhibits exceptional strength and hardness, making it suitable for applications requiring wear resistance and high load-bearing capacity. These properties make nano molybdenum an attractive choice for lubricants, coatings, and structural components.

5. Thermal Conductivity: Nano molybdenum has excellent thermal conductivity, which makes it useful in heat sink applications and electronic devices where efficient heat dissipation is essential.

6. Corrosion Resistance: Molybdenum is inherently resistant to corrosion, and this property is further enhanced at the nanoscale. Nano molybdenum powders can be used to create protective coatings or as a component in corrosion-resistant alloys.

7. Electrical Conductivity: Although not as conductive as metals like copper or silver, nano molybdenum still possesses decent electrical conductivity, making it applicable in certain electronic and electrochemical applications.

8. Dispersion and Processability: The small particle size of nano molybdenum powder facilitates easy mixing and integration into various matrices, including polymers, ceramics, and metals. This allows for the development of novel composite materials with tailored properties.

In conclusion, nano molybdenum powder offers a range of unique properties due to its nanoscale dimensions, making it versatile in numerous industrial applications. From aerospace to automotive, electronics, and energy sectors, this advanced material finds uses in wear-resistant coatings, high-performance alloys, and even in the development of next-generation catalysts and sensors. As research and technology continue to advance, the potential applications of nano molybdenum will only expand.

(Nano molybdenum powder )

FAQs of Nano molybdenum powder

Inquiry us