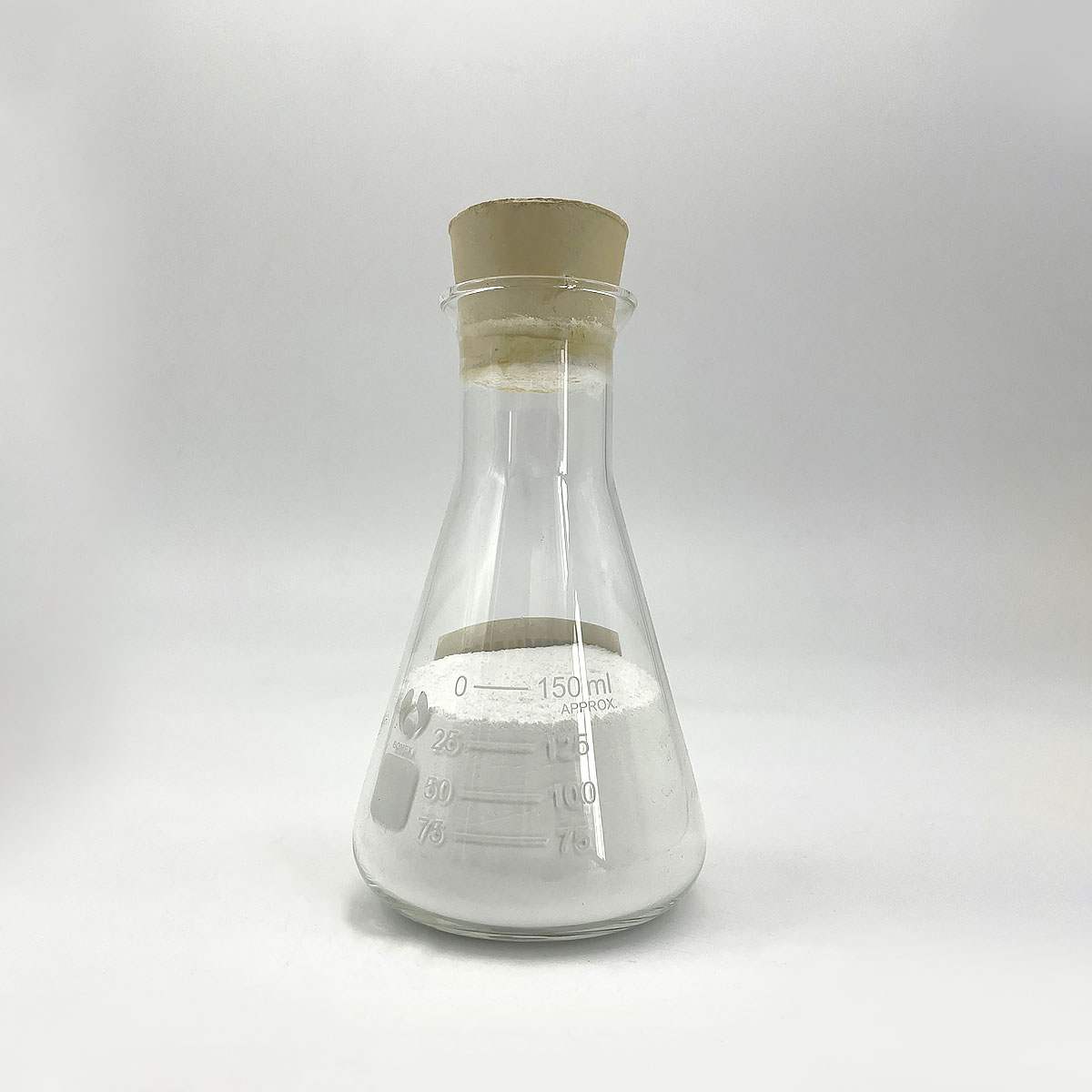

Overview of High Purity 99.9% Nano Molybdenum powder / Molybdenum nanoparticles / Molybdenum powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Purity 99.9% Nano Molybdenum powder / Molybdenum nanoparticles / Molybdenum powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High Purity 99.9% Nano Molybdenum powder / Molybdenum nanoparticles / Molybdenum powder)

Parameters of High Purity 99.9% Nano Molybdenum powder / Molybdenum nanoparticles / Molybdenum powder

Molybdenum, a chemical element with the symbol Mo and atomic number 42, is a crucial component in various industrial applications due to its exceptional properties, particularly high strength, durability, and resistance to corrosion. Our high purity 99.9% nano molybdenum powder, also known as molybdenum nanoparticles or simply molybdenum powder, is a premium material that offers unique benefits compared to its larger particle counterparts.

The nano-sized particles in this product have a diameter ranging from 1 to 100 nanometers, providing a significantly increased surface area-to-volume ratio. This enhanced property allows for improved reactivity, faster diffusion rates, and better mechanical interlocking, making it ideal for applications such as wear-resistant coatings, lubricants, and catalysts.

One of the key features of our molybdenum powder is its exceptional thermal stability, which enables it to maintain its structural integrity under high temperatures. This makes it suitable for use in industries like aerospace, automotive, and power generation, where components are subjected to extreme conditions. Additionally, the high purity level ensures minimal contamination, resulting in improved performance and longer service life.

In the field of electronics and semiconductors, molybdenum is employed as a dopant to enhance the conductivity and stability of materials like tungsten carbide and niobium-titanium alloys. The nano-scale form further enhances these properties by facilitating better control over the microstructure and enhancing the overall performance of electronic devices.

Molybdenum nanoparticles also find applications in biomedicine, where they can be used in targeted drug delivery systems, as well as in tissue engineering scaffolds due to their biocompatibility and osteoinductive properties. Their small size allows for easier penetration into biological tissues, promoting cell growth and regeneration.

In the field of energy storage, molybdenum is a critical component in lithium-ion batteries, where it acts as a cathode material, improving battery capacity and cycle life. The nanostructured form enhances the electrochemical performance by facilitating efficient charge transfer and preventing the formation of large crystals during cycling.

For industrial applications in metal alloys, our molybdenum powder is often used to strengthen and harden steel, making it more resistant to wear and tear. It is also combined with other elements like tungsten or vanadium to create high-strength steels and superalloys used in jet engines and turbine blades.

In summary, our high purity 99.9% nano molybdenum powder is a versatile material with numerous advantages, including superior mechanical properties, enhanced chemical reactivity, and improved performance in various industries. Its unique characteristics make it an essential choice for demanding applications where durability, efficiency, and precision are paramount. With its inherent benefits, we believe it will continue to revolutionize the way industries approach material science and technology.

(High Purity 99.9% Nano Molybdenum powder / Molybdenum nanoparticles / Molybdenum powder)

FAQs of High Purity 99.9% Nano Molybdenum powder / Molybdenum nanoparticles / Molybdenum powder

Inquiry us