Overview of Supply Chemical Catalyst Nano Mo particle Molybdenum Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Supply Chemical Catalyst Nano Mo particle Molybdenum Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

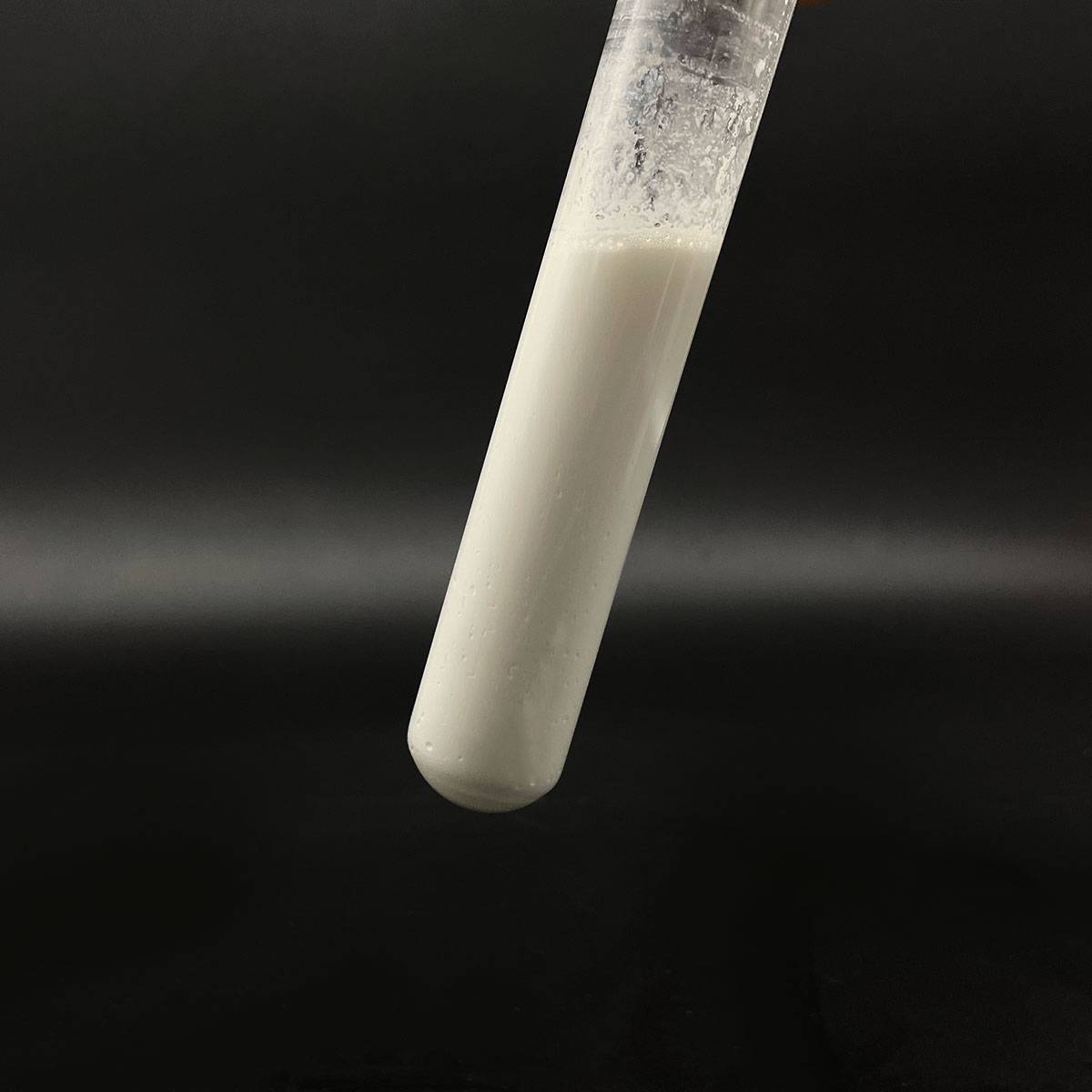

(Supply Chemical Catalyst Nano Mo particle Molybdenum Powder)

Parameters of Supply Chemical Catalyst Nano Mo particle Molybdenum Powder

Chemical Catalyst Nano Mo Particle: A Promising Material for Enhanced Performance

Molybdenum powder, derived from the element molybdenum (Mo), is a highly sought-after material in the realm of chemical catalysts due to its exceptional properties. As a nano-sized catalyst, it exhibits unique characteristics that make it an invaluable component in various industrial applications, from petrochemical processes to environmental remediation.

Nano-molybdenum particles, with their dimensions typically ranging from 1 to 100 nanometers, offer a significantly increased surface area compared to their bulk counterparts. This enhanced surface-to-volume ratio allows for more active sites, enabling the catalyst to interact more efficiently with reactants. The high reactivity and improved selectivity are key factors that contribute to its catalytic prowess.

One of the most notable features of nano Mo particles is their ability to promote redox reactions. They can easily switch between oxidation and reduction states, facilitating crucial chemical transformations. This property makes them ideal for applications such as hydrogenation, where they can lower activation energies, leading to faster reaction rates and improved yield.

In the field of automotive exhaust systems, molybdenum-based catalysts play a vital role in converting harmful pollutants like carbon monoxide and nitrogen oxides into less harmful substances. Nano Mo particles, due to their high catalytic activity, enable these converters to function at lower temperatures, reducing the overall weight and cost of the system.

In the pharmaceutical industry, molybdenum catalysts are employed in the synthesis of complex organic molecules, often acting as promoters or stabilizers in chemical reactions. The small size and high reactivity of nano Mo particles facilitate precise control over reaction pathways, ensuring the production of desired products with minimal side reactions.

Moreover, nano Mo particles find application in water treatment processes, particularly in the removal of heavy metals. Their ability to form stable complexes with contaminants allows for efficient adsorption and subsequent separation, contributing to cleaner water sources.

The stability and durability of nano Mo particles are also worth mentioning. Due to their inherent resistance to deactivation, they can maintain their catalytic efficiency over extended periods, reducing the need for frequent replacement. This aspect is particularly important in industries where catalyst lifetime is a critical factor.

However, the synthesis and handling of nano Mo particles present challenges, including issues related to particle dispersion, aggregation, and potential toxicity. Researchers continually strive to optimize synthesis methods, such as sol-gel, hydrothermal, or chemical vapor deposition, to produce well-dispersed and safe catalysts.

In conclusion, chemical catalyst nano Mo particles hold immense potential in various sectors due to their unique properties, including high reactivity, surface area, and stability. Their ability to enhance chemical reactions and address environmental concerns makes them a valuable addition to the arsenal of catalyst materials. As research continues to advance, we can expect even more innovative applications and improvements in the performance of nano Mo catalysts in the future.

(Supply Chemical Catalyst Nano Mo particle Molybdenum Powder)

FAQs of Supply Chemical Catalyst Nano Mo particle Molybdenum Powder

Inquiry us