Overview of Cobalt Chromium Molybdenum Alloy Powder for 3D Printing Dental

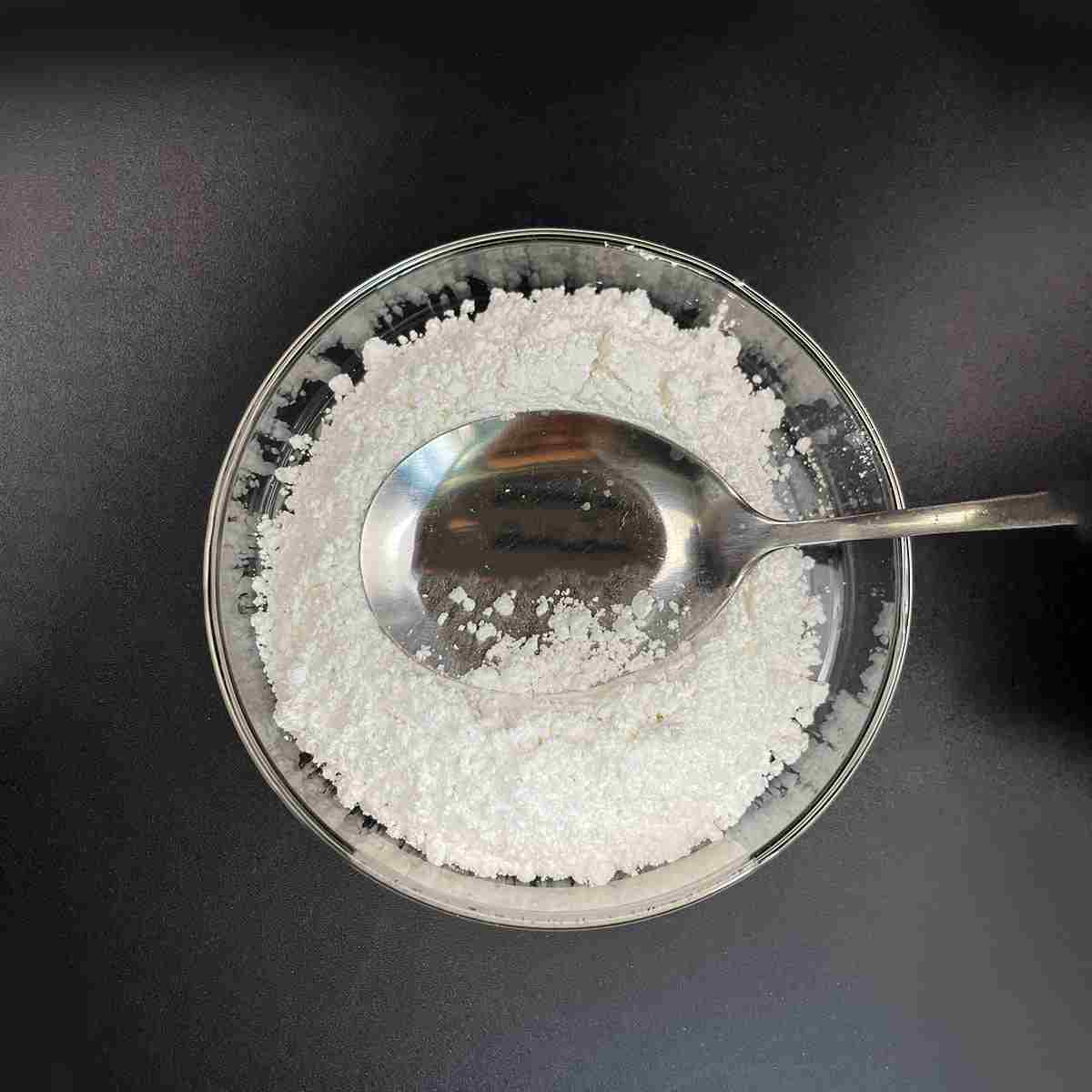

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Cobalt Chromium Molybdenum Alloy Powder for 3D Printing Dental

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Cobalt Chromium Molybdenum Alloy Powder for 3D Printing Dental)

Parameters of Cobalt Chromium Molybdenum Alloy Powder for 3D Printing Dental

Cobalt Chromium Molybdenum (CoCrMo) alloy powder, specifically tailored for 3D printing in dental applications, is a high-performance material that combines the benefits of these three elements to create strong, durable, and biocompatible structures for various dental prosthetics. This advanced technology has revolutionized the way dental professionals fabricate restorations, implants, and orthodontic appliances.

Cobalt Chromium, or Co-Cr, is the primary component of the alloy, known for its excellent strength, wear resistance, and corrosion resistance. It boasts a high melting point, ensuring that the printed parts maintain their integrity under heavy loads and prolonged use. The material’s biocompatibility makes it suitable for direct contact with oral tissues, reducing the risk of allergic reactions or inflammation.

Molybdenum (Mo), on the other hand, enhances the mechanical properties of the CoCrMo blend. It improves the alloy’s toughness, creep resistance, and resistance to stress corrosion, which translates to better longevity and durability of the printed dental components. This element also contributes to the smooth surface finish and improved aesthetics, making the final product more pleasing to both patients and dental professionals.

The 3D printing process using CoCrMo alloy powder typically involves additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). These methods enable the creation of intricate geometries and precise layer-by-layer deposition, ensuring a high level of accuracy and customization for each dental case. The powder particles, usually in a spherical or sub-micron form, are precisely directed onto a build platform, where they fuse together under intense heat and energy, forming the desired part.

One of the critical aspects of CoCrMo 3D printing in dentistry is its ability to achieve a near-net-shape fabrication, reducing waste and minimizing the need for additional post-processing steps. This results in cost savings and shortened production times, ultimately benefiting both the dental practice and patients.

When it comes to the specific parameters for 3D printing CoCrMo dental materials, these include:

1. Particle size: The ideal particle size ranges from 25-50 microns, ensuring optimal fusion during the printing process and achieving a uniform microstructure.

2. Layer thickness: A typical layer thickness of 10-30 microns is used, providing adequate resolution while maintaining structural integrity.

3. Laser power and speed: Depending on the equipment, laser power may vary between 100-400 watts, with scanning speeds of around 500-1000 mm/s, to achieve a balance between quality and efficiency.

4. Build orientation: To minimize stress and ensure proper bonding between layers, parts are often printed with a specific orientation, like a “build-up direction” parallel to the gingival margin.

5. Post-processing: After printing, parts may require grinding, polishing, and firing to achieve the final shape and improve surface finish, as well as to remove any remaining unmelted powder.

In conclusion, Cobalt Chromium Molybdenum alloy powder for 3D printing in dental applications offers a versatile and technologically advanced solution for creating customized restorative solutions. Its unique combination of properties, coupled with the precision of 3D printing, promises improved patient outcomes, reduced costs, and enhanced workflow efficiency for dental practitioners.

(Cobalt Chromium Molybdenum Alloy Powder for 3D Printing Dental)

FAQs of Cobalt Chromium Molybdenum Alloy Powder for 3D Printing Dental

Inquiry us