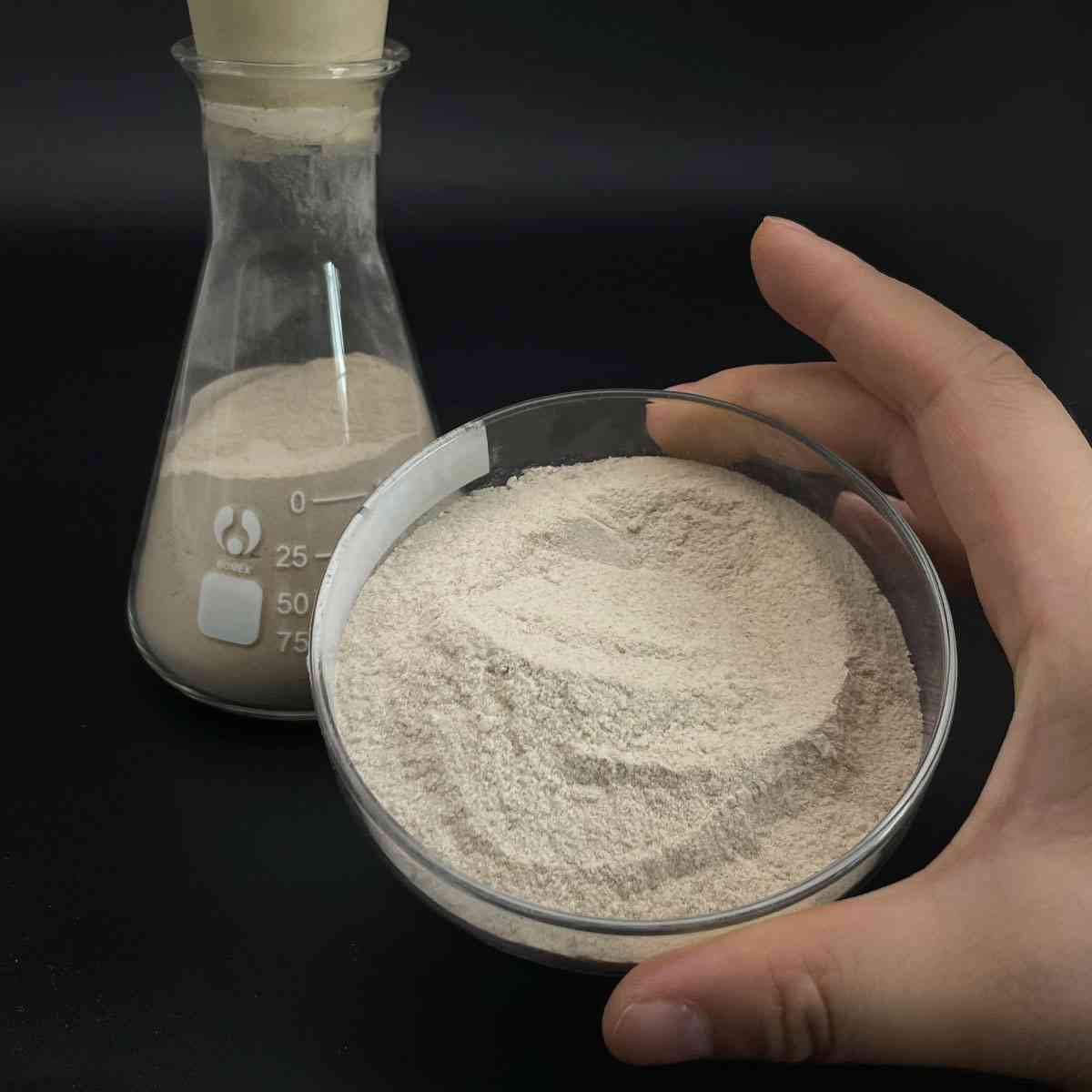

Overview of 99.9% Molybdenum Disulfide Powder 200nm Good Conductivity Nano powder MoS2 For Lubricant

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 99.9% Molybdenum Disulfide Powder 200nm Good Conductivity Nano powder MoS2 For Lubricant

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(99.9% Molybdenum Disulfide Powder 200nm Good Conductivity Nano powder MoS2 For Lubricant)

Parameters of 99.9% Molybdenum Disulfide Powder 200nm Good Conductivity Nano powder MoS2 For Lubricant

Molybdenum disulfide (MoS2), with a purity level of 99.9%, is a highly sought-after nanomaterial due to its exceptional properties, particularly in the form of 200 nanometer-sized particles. These nano-sized MoS2 powders exhibit remarkable conductivity, which makes them an ideal component for various applications, including lubricants.

Good conductivity is a key feature of this MoS2 powder, as it facilitates efficient heat transfer and electrical current flow. At the nanoscale, the large surface area to volume ratio enhances the material’s inherent ability to conduct electricity, making it suitable for use in electronic devices and energy storage systems where high conductivity is crucial for performance.

In the context of lubricants, MoS2 nanoparticles play a transformative role. They act as a superior lubricant additive, reducing friction and wear between moving parts. The ultrafine particles can form a protective film on metal surfaces, minimizing contact and preventing abrasive damage. This results in improved efficiency, extended equipment lifespan, and reduced maintenance costs.

Moreover, the 200nm particle size ensures that the MoS2 is evenly dispersed within the lubricant, providing consistent and uniform protection. Smaller particles tend to penetrate deeper into the surface grooves, providing better coverage and lubrication under extreme conditions. This is particularly beneficial in industries such as automotive, aerospace, and manufacturing, where reliability and efficiency are paramount.

The lubricant parameter for this MoS2 powder also includes excellent anti-wear properties, reducing the formation of abrasive debris that could cause system degradation. It exhibits good thermal stability, allowing it to maintain its lubricating properties even under high temperatures, which is essential for applications involving machinery operating at elevated temperatures.

Furthermore, molybdenum disulfide is known for its chemical inertness, ensuring compatibility with a wide range of materials. Its non-reactive nature prevents corrosion and protects surfaces from chemical attack, contributing to longer-lasting lubrication and improved overall system performance.

In summary, the 99.9% pure MoS2 powder with a particle size of 200nm is a high-performance material due to its exceptional conductivity, superior lubrication capabilities, and durable properties. It offers a significant advantage in enhancing the efficiency and longevity of lubricants across various industries, making it a valuable addition to modern technologies and processes. Its unique characteristics make it a standout choice for demanding applications where reliability and performance are non-negotiable.

(99.9% Molybdenum Disulfide Powder 200nm Good Conductivity Nano powder MoS2 For Lubricant)

FAQs of 99.9% Molybdenum Disulfide Powder 200nm Good Conductivity Nano powder MoS2 For Lubricant

Inquiry us