Overview of 60-300 Mesh, 2-10 Um Molybdenum Carbide Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 60-300 Mesh, 2-10 Um Molybdenum Carbide Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

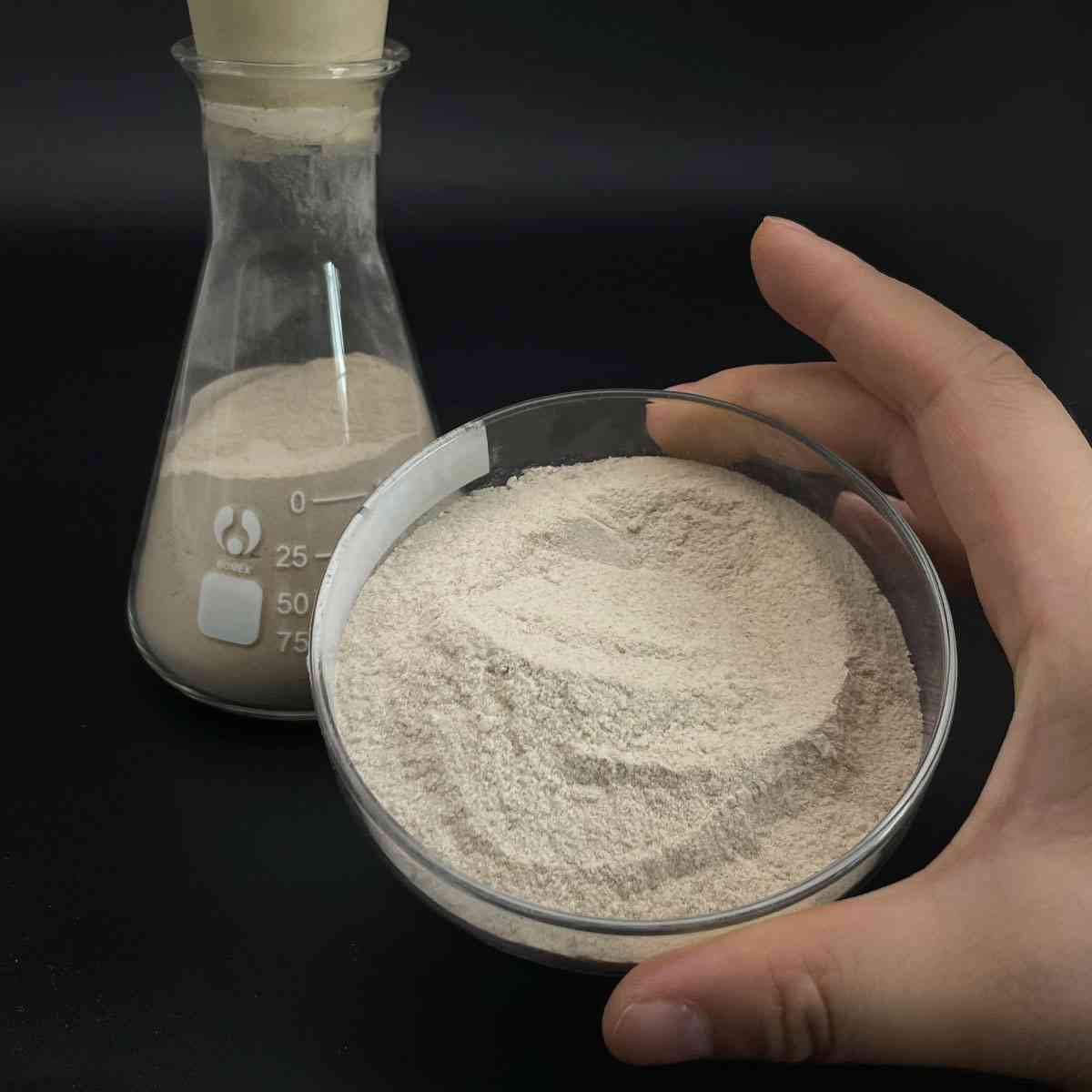

(60-300 Mesh, 2-10 Um Molybdenum Carbide Powder)

Parameters of 60-300 Mesh, 2-10 Um Molybdenum Carbide Powder

Molybdenum carbide (MoC) powder, with particle sizes ranging from 60 to 300 mesh and an average diameter of 2 to 10 micrometers, is a high-performance material known for its exceptional strength, wear resistance, and thermal stability. This particular grade of powder is commonly used in various industrial applications due to its unique combination of properties.

The 60 mesh size indicates that the particles have an average diameter of approximately 45 micrometers, while the 300 mesh corresponds to a smaller particle size of about 74 micrometers. The narrow size distribution ensures a consistent material flow and better packing density, which is crucial for achieving optimal performance in processes like sintering or consolidation.

Molybdenum carbide possesses a high melting point, around 2890°C, making it suitable for applications where elevated temperatures are involved. It has an extremely low coefficient of friction, reducing wear and tear on mechanical components, particularly in sliding or rubbing surfaces. This property makes it ideal for use in bearings, cutting tools, and wear-resistant coatings.

The 2-10 micron particle size range offers versatility in manufacturing. Smaller particles can result in higher surface area, facilitating better bonding during compaction or sintering, while larger particles provide better mechanical stability and resistance to deformation. This characteristic allows for tailoring the powder’s properties to suit specific application requirements.

In terms of chemical stability, molybdenum carbide is resistant to acids and alkalis, as well as corrosion, making it suitable for harsh environments. Its hardness, measured on the Mohs scale, is typically around 8.5 to 9.5, indicating its durability and ability to maintain shape under pressure.

Processing molybdenum carbide powder often involves techniques like ball milling, attrition milling, or gas atomization to achieve the desired particle size and morphology. Post-processing treatments, such as annealing or sintering, further enhance its mechanical properties and ensure a homogeneous structure.

In conclusion, the 60-300 mesh, 2-10 micron molybdenum carbide powder is a premium material choice for industries like aerospace, automotive, and manufacturing, where high wear resistance, thermal stability, and precise control over particle size are essential. Its versatile nature and exceptional properties make it an indispensable component in various engineering applications, from cutting tools to wear-resistant coatings, where reliability and efficiency are paramount.

(60-300 Mesh, 2-10 Um Molybdenum Carbide Powder)

FAQs of 60-300 Mesh, 2-10 Um Molybdenum Carbide Powder

Inquiry us