Overview of sullpy LVDA titanium powder nickel powder metal microporous powder sintered filter element

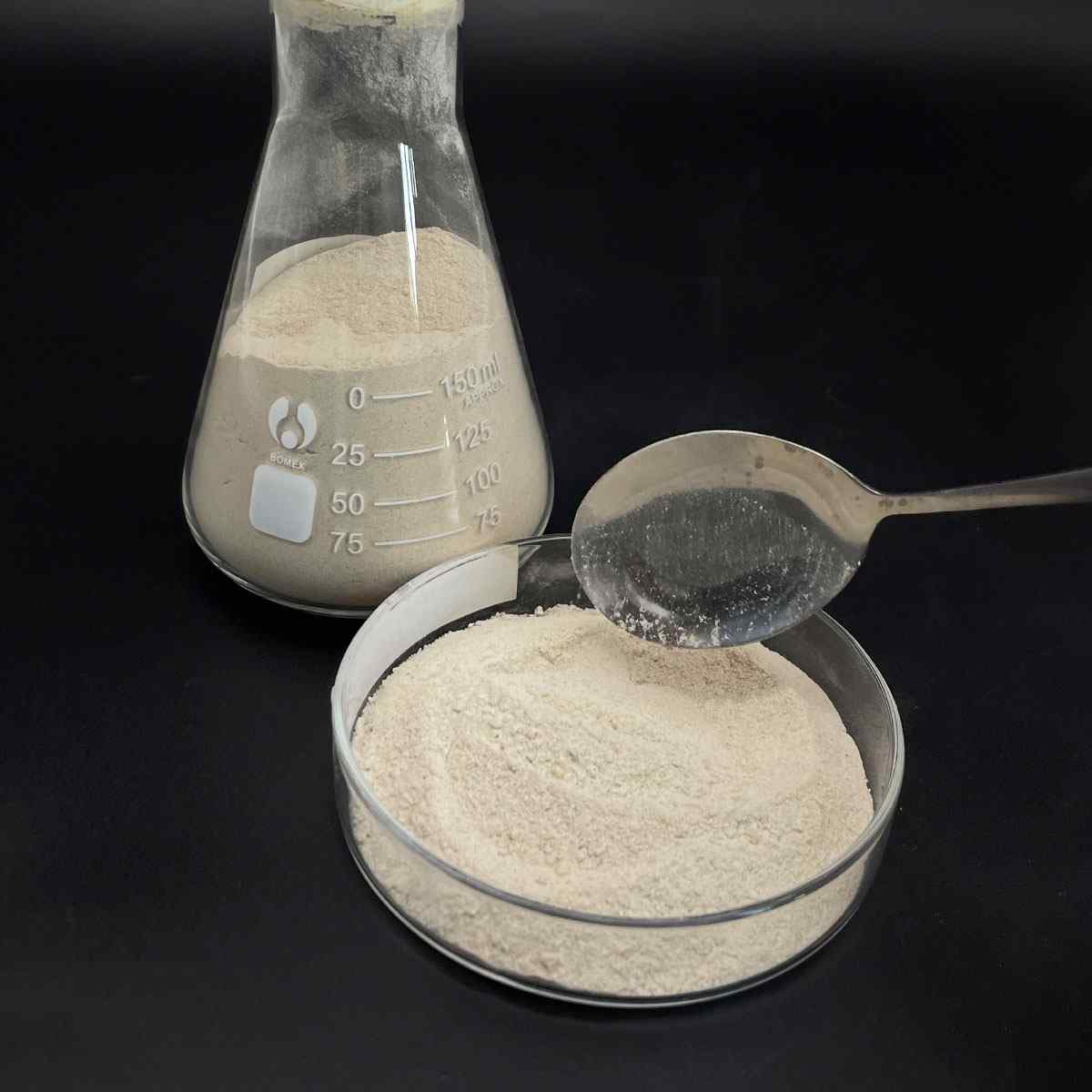

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of sullpy LVDA titanium powder nickel powder metal microporous powder sintered filter element

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(sullpy LVDA titanium powder nickel powder metal microporous powder sintered filter element)

Parameters of sullpy LVDA titanium powder nickel powder metal microporous powder sintered filter element

Sintered Filter Elements: A Comprehensive Overview of LVDA Titanium and Nickel Powders

In the realm of industrial filtration technology, sintered filter elements play a vital role in various applications, from aerospace to automotive, pharmaceuticals, and environmental control systems. One such innovative material is the combination of LVDA (Laminated Varying Density) titanium and nickel powders, which offer exceptional performance, durability, and adaptability. This text aims to provide an in-depth look at the key parameters of these microporous filters without adhering to a specific format.

LVDA Titanium Powder:

Titanium, known for its high strength-to-weight ratio and excellent corrosion resistance, is often employed in sintered filter elements. The LVDA process involves layering titanium powders with varying particle sizes, creating a porous structure that enhances mechanical strength and surface area. Key parameters for LVDA titanium powder include:

1. Particle Size Distribution: The uniformity of particle size directly impacts the porosity and flow characteristics of the final product. Smaller particles contribute to higher surface area, while larger ones ensure structural integrity.

2. Porosity: The percentage of void space within the titanium matrix is crucial for efficient filtration and gas flow. LVDA processing allows for controlled porosity, optimizing performance in specific applications.

3. Density Gradient: The varying density in LVDA design results in improved mechanical properties, as the denser layers provide structural support, while the less dense layers facilitate gas passage.

4. Thermal Stability: Titanium’s high melting point ensures the stability of the sintered element under elevated temperatures, essential for high-temperature applications.

LVDA Nickel Powder:

Nickel, another popular choice for sintered filters, is renowned for its high conductivity, magnetic properties, and resistance to oxidation. LVDA nickel powder filter elements exhibit:

1. Composition: Nickel alloys like Ni-800 or Ni-based superalloys are commonly used, offering excellent thermal and mechanical properties.

2. Microstructure: The layered microstructure of LVDA nickel powder enables a balance between strength and permeability, enhancing filter performance.

3. Corrosion Resistance: Nickel’s inherent resistance to corrosion makes it suitable for harsh environments, minimizing fouling and extending filter life.

4. Surface Finish: The sintering process results in a smooth surface, which reduces fouling and improves cleaning efficiency.

Sintered Filter Element Parameters:

When combined, titanium and nickel powders create a composite material with enhanced properties. Key parameters for the sintered filter elements include:

1. Filter Efficiency: The ability to remove contaminants from the flow, typically measured in terms of pressure drop and particle retention.

2. Service Life: The duration the filter can operate before requiring maintenance or replacement, influenced by particle loading, temperature, and service conditions.

3. Compatibility: Suitability for specific gases, fluids, or chemicals, ensuring minimal interaction and maintaining optimal performance.

4. Thermal Conductivity: Combined titanium and nickel elements exhibit improved heat dissipation, reducing the risk of overheating.

5. Mechanical Strength: The overall rigidity and resilience of the filter element, allowing it to withstand pressure fluctuations and handling.

In conclusion, LVDA titanium and nickel powder sintered filter elements offer a unique blend of properties that cater to a wide range of applications. Their tailored composition, microstructure, and sintering process enable superior filtration performance, durability, and adaptability. Understanding these parameters is essential for engineers and technicians seeking to optimize their filtration systems in various industries.

(sullpy LVDA titanium powder nickel powder metal microporous powder sintered filter element)

FAQs of sullpy LVDA titanium powder nickel powder metal microporous powder sintered filter element

Inquiry us