Overview of The platinum coating Titanium Expanded Flatten and annealed mesh

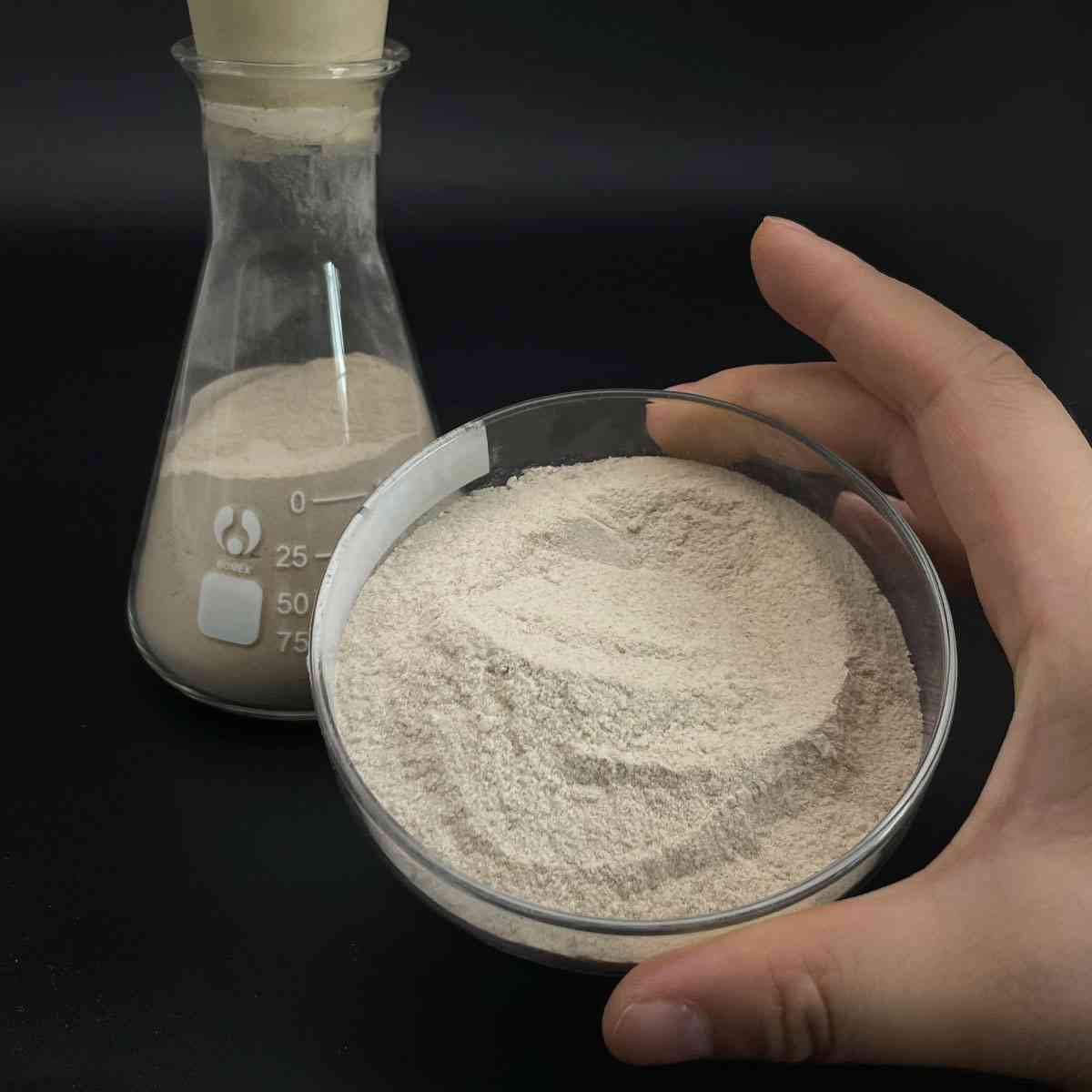

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of The platinum coating Titanium Expanded Flatten and annealed mesh

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(The platinum coating Titanium Expanded Flatten and annealed mesh)

Parameters of The platinum coating Titanium Expanded Flatten and annealed mesh

Title: Technical Specifications of Platinum-Coated Titanium Expanded and Annealed Mesh

Introduction:

Titanium Expanded Flat and Annealed Mesh, with its inherent strength and corrosion resistance, is a high-performance material that finds extensive applications in various industries, including aerospace, medical, and filtration. The addition of a platinum coating further enhances its properties, providing exceptional durability and conductivity. This technical overview will delve into the key parameters of this platinum-coated titanium mesh.

1. Material Composition:

The base material is Grade 2 or Grade 5 titanium, known for its lightweight, high strength-to-weight ratio, and biocompatibility. It consists of approximately 99.5% pure titanium, ensuring the mesh’s integrity and performance.

2. Coating Process:

The platinum coating is applied through an electroplating technique, which deposits a thin layer of pure platinum onto the titanium surface. This process ensures a uniform and consistent thickness, typically ranging from 0.5 to 5 microns, depending on the specific application requirements.

3. Mesh Construction:

The expanded titanium mesh is initially fabricated by stretching and rolling the raw titanium sheets to create a fine, open structure. The process results in a porous and flexible material with high surface area, allowing for efficient heat transfer and gas flow.

4. Annealing:

After expansion, the mesh undergoes annealing, which is a controlled heating and cooling process. This step strengthens the material, reduces internal stresses, and improves the overall mechanical properties. The annealing temperature is usually between 800°C to 1000°C, ensuring optimal grain structure for enhanced durability.

5. Dimensions and Tolerance:

The platinum-coated titanium expanded mesh can be customized in various sizes and shapes, including rectangular, circular, or hexagonal patterns. The dimensions are specified according to industry standards, with tolerances of ±0.1mm for width, length, and thickness to maintain precision and consistency.

6. Surface Finish:

The annealed mesh features a smooth and shiny surface due to the platinum coating. The finish is often mirror-like, providing excellent reflectivity and resistance to corrosion and tarnish.

7. Electrical Conductivity:

The platinum coating significantly enhances the electrical conductivity of the titanium mesh, making it suitable for applications requiring high conductivity, such as in electronic components or as a heat exchanger.

8. Chemical Resistance:

The combination of titanium and platinum makes the mesh highly resistant to most acids, alkalis, and salt solutions, ensuring long-term performance in harsh environments.

9. Environmental Impact:

The use of platinum-coated titanium mesh promotes sustainability, as both materials are recyclable and have low environmental footprints. The platinum layer also contributes to the mesh’s resistance to degradation, reducing waste generation.

10. Applications:

This advanced material finds applications in areas like chemical processing, fuel cells, catalytic converters, medical implants, and aerospace components due to its unique properties, including thermal stability, corrosion resistance, and high electrical conductivity.

In conclusion, the platinum-coated titanium expanded and annealed mesh is a premium material designed for demanding applications. Its precise specifications ensure optimal performance, while the platinum coating adds valuable properties like conductivity and durability. By understanding these parameters, engineers and manufacturers can select the most appropriate mesh for their projects.

(The platinum coating Titanium Expanded Flatten and annealed mesh)

FAQs of The platinum coating Titanium Expanded Flatten and annealed mesh

Inquiry us