Overview of Best material for zirconium plate ZrC Supply High Purity Submicron Ceramics metal niobium Zirconium carbide powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Best material for zirconium plate ZrC Supply High Purity Submicron Ceramics metal niobium Zirconium carbide powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Best material for zirconium plate ZrC Supply High Purity Submicron Ceramics metal niobium Zirconium carbide powder)

Parameters of Best material for zirconium plate ZrC Supply High Purity Submicron Ceramics metal niobium Zirconium carbide powder

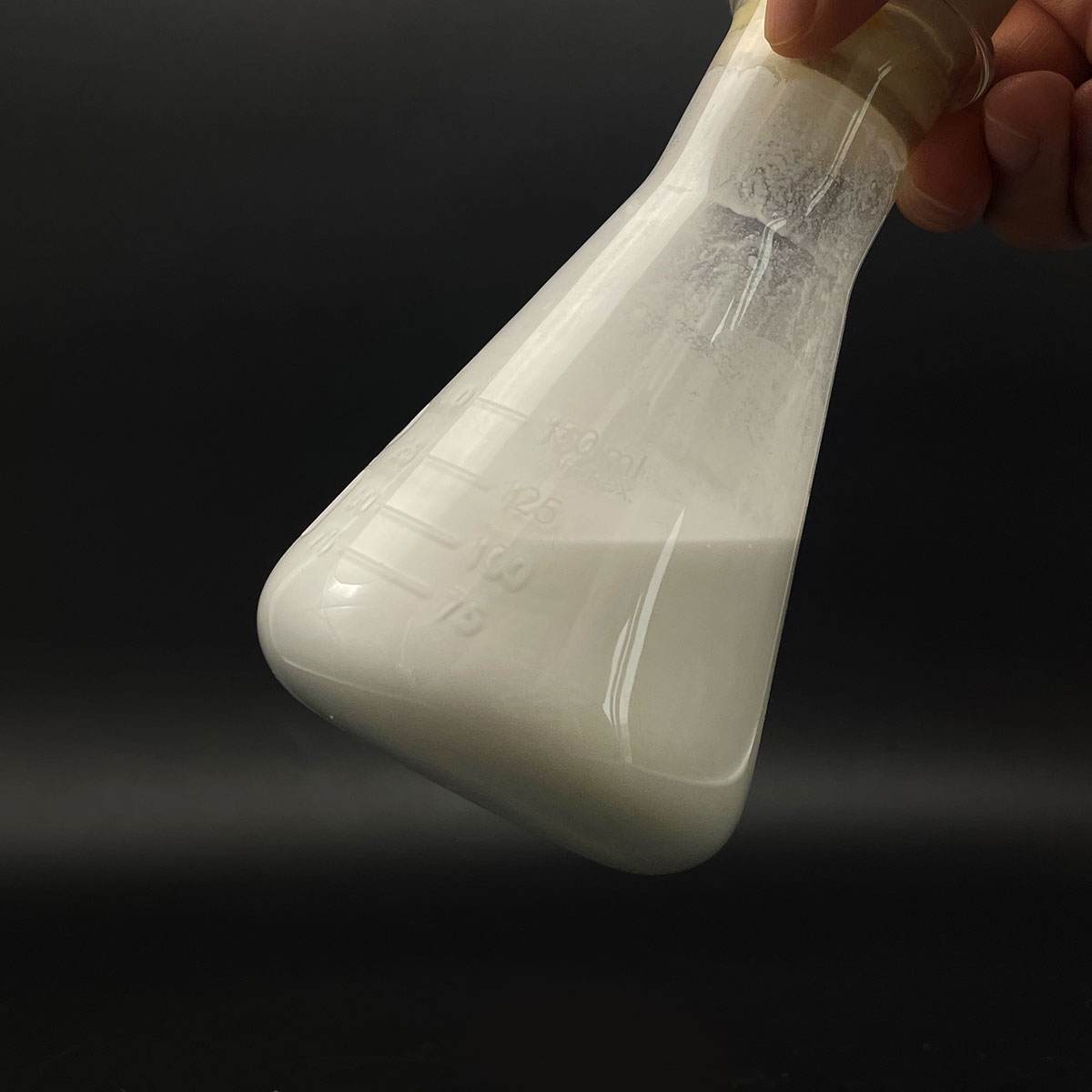

Zirconium carbide (ZrC), also known as zirconium monocarbide, is an advanced ceramic material that has gained significant attention due to its exceptional properties and wide range of applications. It is synthesized by combining zirconium (Zr) and carbon (C) at high temperatures, resulting in a compound with a hexagonal crystal structure. Among the various materials available for zirconium plates, ZrC stands out for its unique characteristics.

One of the primary reasons ZrC is considered the best material for certain applications is its high melting point, which exceeds 3600°C. This makes it highly resistant to thermal degradation and suitable for use in extreme environments, such as in high-temperature aerospace, military, and energy industries where components need to withstand intense heat.

ZrC possesses excellent mechanical strength, with a compressive strength typically above 25 GPa, making it one of the hardest ceramics after diamond. Its hardness allows it to maintain integrity under heavy loads and resist wear, making it ideal for applications like cutting tools, wear-resistant coatings, and mechanical components.

Another critical feature of ZrC is its chemical inertness. It resists corrosion from most acids, alkalis, and molten salts, ensuring long-term durability in corrosive environments. This property makes it an ideal choice for components in chemical processing, nuclear power plants, and fuel cells.

Furthermore, ZrC exhibits low thermal expansion coefficients, which minimizes stress induced during temperature changes. This stability is crucial for maintaining precise dimensions in precision engineering and manufacturing components that require tight tolerances.

In terms of supply, high-purity submicron Zirconium carbide powder is readily available from reputable manufacturers. These powders, with particle sizes ranging from nano to sub-micron scales, can be processed into various forms, including sintered parts, composite materials, or as a coating, depending on the application requirements.

However, it’s important to note that ZrC’s brittleness can be a concern, especially when subjected to impact or sudden stress. To address this, researchers and manufacturers often combine ZrC with other materials, such as metals or matrix composites, to improve toughness and fracture resistance.

In summary, ZrC is an outstanding material for zirconium plates due to its high melting point, exceptional mechanical strength, chemical stability, and low thermal expansion. While its brittleness is a consideration, advancements in processing techniques have made it a viable option in various industries, from aerospace to energy. The availability of high-purity submicron ceramics ensures consistent performance and reliable manufacturing processes. As technology continues to evolve, ZrC is poised to play an increasingly important role in the future of advanced materials science.

(Best material for zirconium plate ZrC Supply High Purity Submicron Ceramics metal niobium Zirconium carbide powder)

FAQs of Best material for zirconium plate ZrC Supply High Purity Submicron Ceramics metal niobium Zirconium carbide powder

Inquiry us