Overview of Spherical Niobium C103 Alloy Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Spherical Niobium C103 Alloy Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

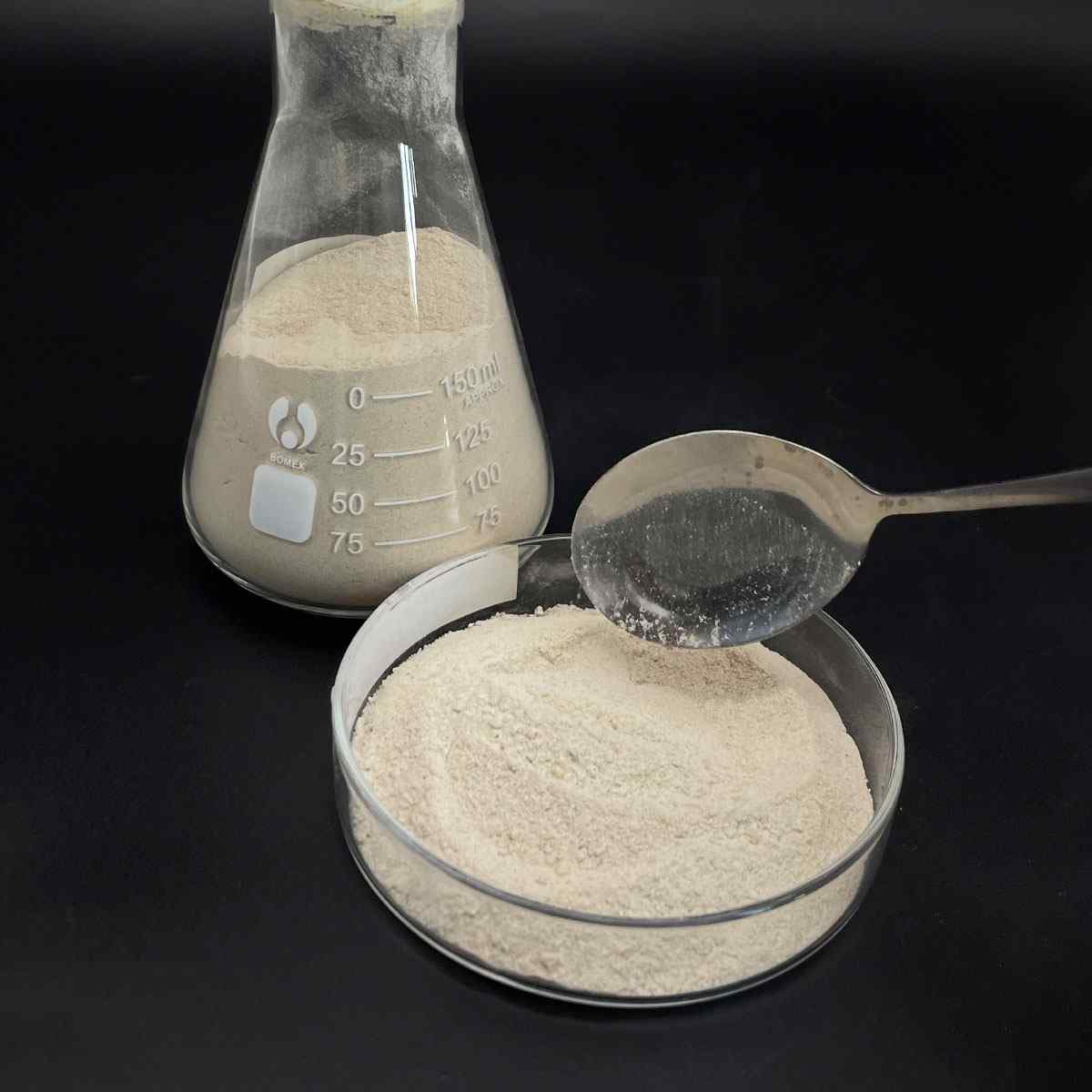

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

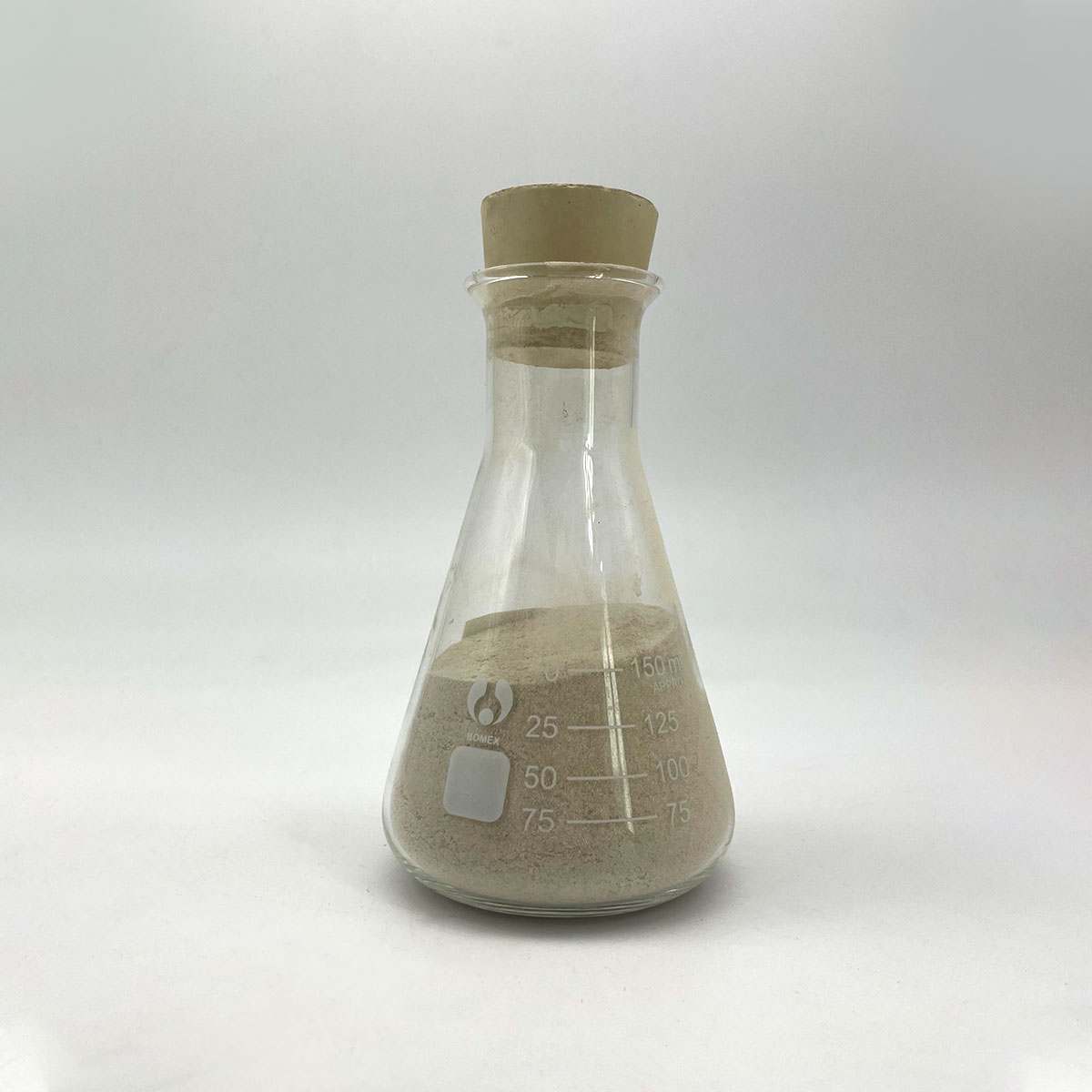

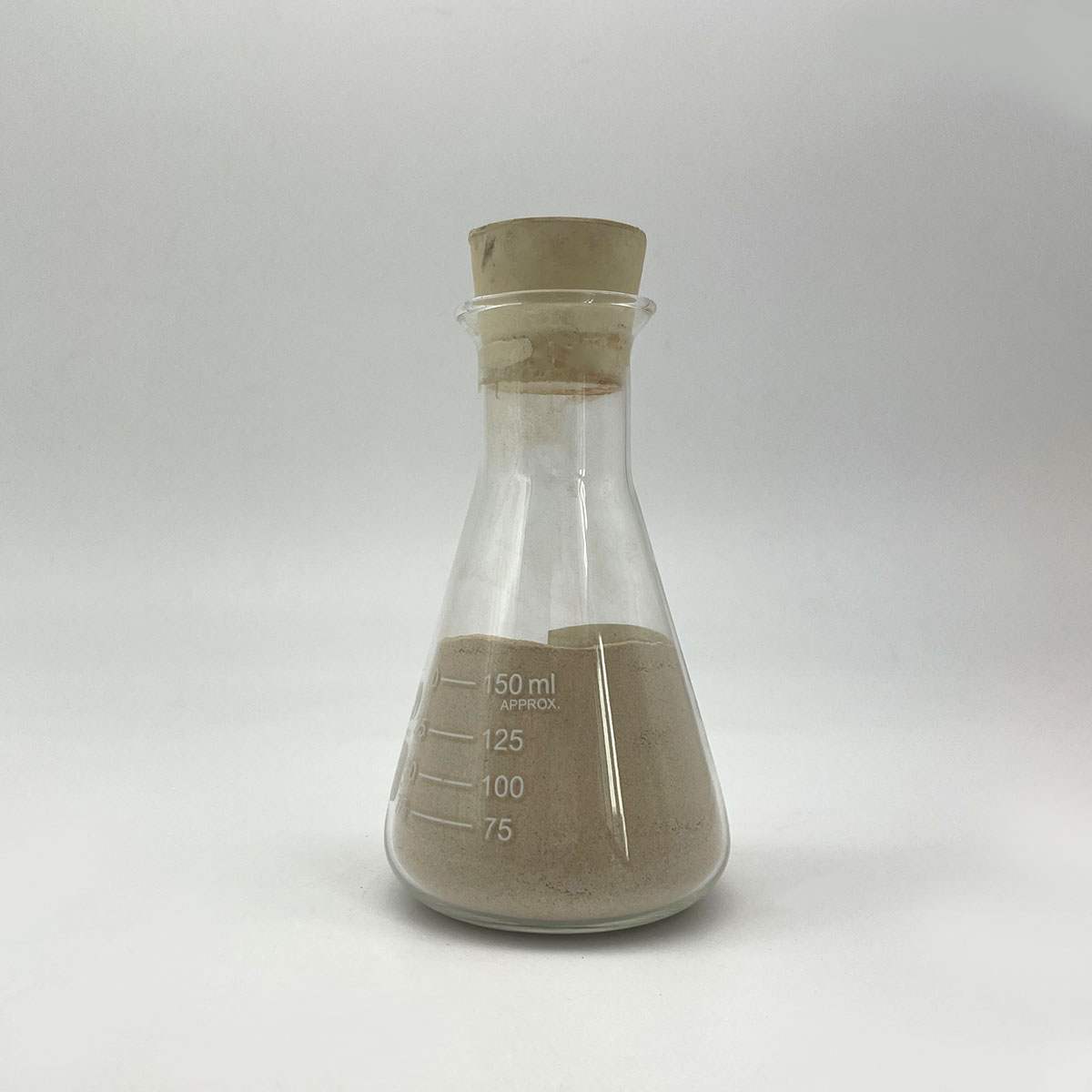

(Spherical Niobium C103 Alloy Powder)

Parameters of Spherical Niobium C103 Alloy Powder

Spherical Niobium C103 alloy powder is a high-performance material that finds extensive applications in various industries, particularly in the fields of superconductivity, aerospace, and advanced manufacturing. This unique powder form is characterized by its exceptional properties, which make it stand out from conventional materials.

Niobium C103 (NbC103) is a composite material composed of niobium (Nb), a rare-earth element known for its strong magnetic and thermal conductivity, and carbon (C), providing structural reinforcement and enhancing mechanical strength. The spherical shape of the particles is crucial, as it offers several advantages over other particle geometries. Spherical particles have a more uniform distribution in the final product, leading to improved flowability and reduced agglomeration during processing, resulting in better density and homogeneity.

The key parameters of this alloy powder are:

1. Particle Size Distribution: The particles in Niobium C103 typically range from 5 to 100 microns, with a narrow size distribution to ensure consistent performance across different applications. The precise control over particle size is essential for achieving optimal sintering characteristics and minimizing defects.

2. Purity: High purity niobium is used to minimize impurities, ensuring the material’s superior superconducting and magnetic properties. The purity level is usually above 99.9% to maintain the desired properties.

3. Crystal Structure: The C103 phase refers to a specific crystal structure where niobium and carbon are intimately bonded. This structure provides excellent mechanical stability and resistance to deformation under stress.

4. Superconducting Properties: Niobium C103 is a type-II superconductor, meaning it can carry large electrical currents without resistance below a critical temperature. Its critical temperature (Tc) is around 9.2 K (-263.9°C), making it suitable for cryogenic applications.

5. Mechanical Strength: The addition of carbon enhances the alloy’s mechanical strength, enabling it to withstand elevated temperatures and pressures without significant degradation. This property is vital for applications like heat exchangers and turbine blades.

6. Sinterability: The spherical shape facilitates better sintering, a process where powders compact into a solid piece. The high degree of sinterability allows for densification and the formation of a strong, homogeneous structure.

7. Thermal Conductivity: Niobium C103 exhibits excellent thermal conductivity, which is crucial for applications where heat transfer is a concern, such as in electronic devices and cooling systems.

8. Chemical Resistance: The material exhibits good chemical stability, making it resistant to corrosion in various environments, a desirable feature for aerospace and nuclear applications.

In conclusion, Niobium C103 alloy powder is a versatile material with a combination of unique properties that make it ideal for demanding applications. Its spherical shape, high purity, and exceptional superconducting and mechanical characteristics make it an attractive choice for industries seeking high-performance materials in cryogenic, high-temperature, and high-stress environments. By understanding and optimizing these parameters, engineers can harness the full potential of this extraordinary material.

(Spherical Niobium C103 Alloy Powder)

FAQs of Spherical Niobium C103 Alloy Powder

Inquiry us