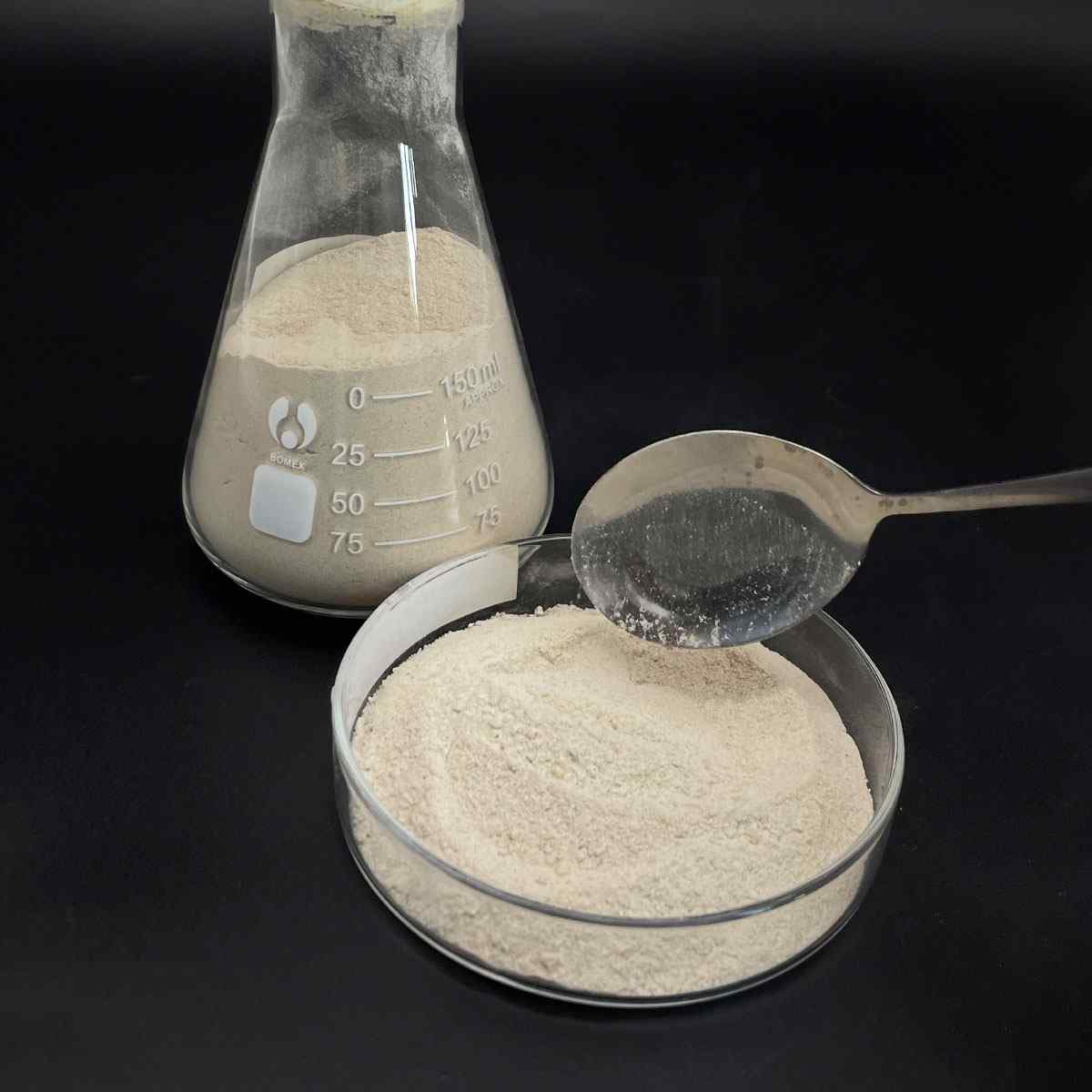

Overview of 3D Printing Powder Pure Niobium Powder 99.8% Nb Powder for

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 3D Printing Powder Pure Niobium Powder 99.8% Nb Powder for

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(3D Printing Powder Pure Niobium Powder 99.8% Nb Powder for )

Parameters of 3D Printing Powder Pure Niobium Powder 99.8% Nb Powder for

3D Printing with Pure Niobium Powder: A High-Purity Solution for Advanced Applications

Niobium, a chemical element with the symbol Nb and atomic number 41, has recently gained significant attention in the realm of 3D printing due to its unique properties. At 99.8% purity, our niobium powder offers exceptional performance for various applications where high strength, corrosion resistance, and superconductivity are critical requirements. This pure form of niobium allows for unparalleled precision and accuracy when used in additive manufacturing processes.

In the world of 3D printing, niobium powder stands out as an unconventional yet promising material. Unlike traditional metals like steel or aluminum, which have been widely adopted, niobium’s low thermal conductivity and high melting point (2750°C) make it ideal for creating components that need to withstand extreme temperatures. It is particularly useful in industries such as aerospace, energy, and medical devices, where parts subjected to cryogenic environments or high-temperature operations are common.

One of the key benefits of using pure niobium powder in 3D printing is its ability to produce intricate geometries with excellent dimensional stability. The powder’s fine particle size ensures a smooth surface finish and minimal porosity, resulting in components with reduced weight and enhanced mechanical integrity. This is particularly advantageous for lightweight designs, such as in the development of satellite components or racing components that need to shave every gram for optimal performance.

Moreover, niobium’s inherent corrosion resistance makes it an attractive choice for applications in marine, chemical, and nuclear industries. Its compatibility with harsh environments means that printed parts can maintain their structural integrity over extended periods, reducing maintenance costs and enhancing safety.

The use of pure niobium powder in 3D printing also opens up possibilities for exploring novel superconducting applications. Niobium alloys exhibit superconductivity below a certain temperature, enabling the creation of electromagnetic devices with zero electrical resistance. This capability could revolutionize areas like power transmission, magnetic levitation systems, and even quantum computing.

However, it’s important to note that 3D printing with pure niobium powder comes with some challenges. The high melting point requires specialized equipment and techniques, often involving selective laser melting (SLM) or electron beam melting (EBM), which can be more complex and time-consuming compared to other metals. Additionally, the cost of the pure niobium powder is higher than conventional options, which may impact the overall economics of the manufacturing process.

In conclusion, pure niobium powder presents a promising alternative for 3D printing, unlocking new opportunities in industries that demand extreme conditions and cutting-edge technology. As research and development continue to refine the processes and optimize the use of this material, we can expect to see a growing array of innovative applications emerge, pushing the boundaries of what’s possible with this extraordinary metal. However, it’s a journey that requires careful consideration of material properties, manufacturing methods, and cost-effectiveness to fully harness the potential of this high-purity niobium powder.

(3D Printing Powder Pure Niobium Powder 99.8% Nb Powder for )

FAQs of 3D Printing Powder Pure Niobium Powder 99.8% Nb Powder for

Inquiry us