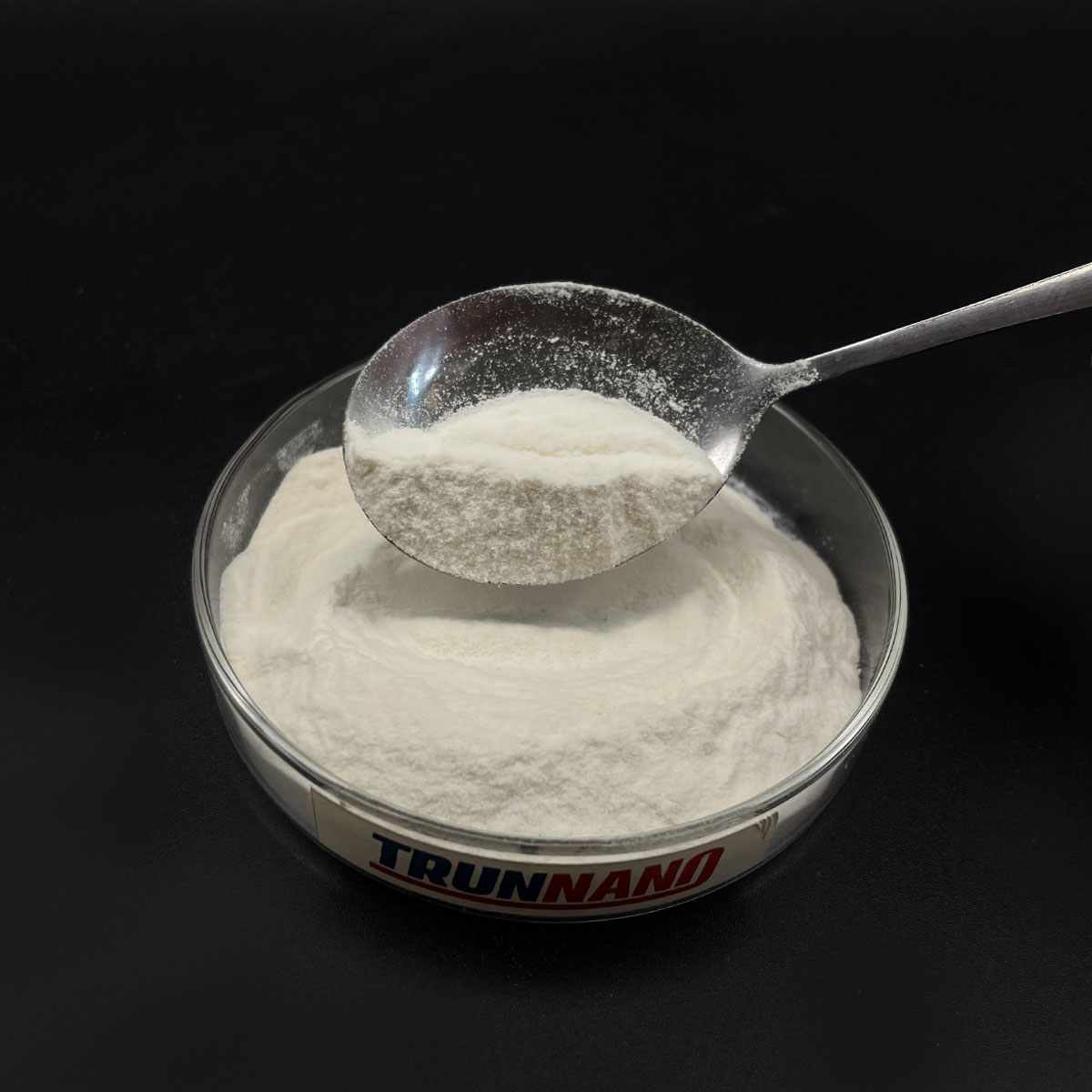

Overview of Metal Ta Powder Tantalum powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Metal Ta Powder Tantalum powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Metal Ta Powder Tantalum powder)

Parameters of Metal Ta Powder Tantalum powder

Metal tantalum, also known as tantalum powder, is a high-performance material with exceptional properties that make it indispensable in various industries. Tantalum, with the chemical symbol Ta, is a rare, lustrous transition metal found in the periodic table’s 7th group. It is characterized by its strong resistance to corrosion, heat, and wear, making it ideal for demanding applications.

Tantalum powder, which is produced by grinding or milling tantalum ingots into fine particles, boasts a unique combination of attributes. The particle size can vary significantly, from submicron to micron levels, depending on the specific application requirements. The purity of tantalum powder is typically greater than 99.5%, ensuring minimal impurities that could affect performance.

One of the most striking features of tantalum powder is its exceptional strength-to-weight ratio. It has a high melting point, around 3,287 degrees Celsius (6,231 degrees Fahrenheit), which makes it an excellent conductor of heat and electricity, even at elevated temperatures. This property makes it suitable for use in high-temperature components like aerospace engines, electronics, and chemical processing equipment.

Tantalum’s inherent corrosion resistance, both in air and aqueous environments, is another key advantage. It forms a protective oxide layer upon exposure to oxygen, which prevents further corrosion, making it ideal for use in harsh conditions, such as nuclear reactors and fuel cells. This durability extends to chemical compatibility with a wide range of acids and alkalis, ensuring long-term service life.

In the field of electronics, tantalum capacitors are commonly used due to their stability and reliability over a wide temperature range. The metal tantalum powder is pressed or sintered into thin films to create these capacitors, which are crucial in electronic devices for filtering and energy storage.

Furthermore, tantalum is employed in medical applications, where it is used in orthopedic implants and dental prosthetics. Its biocompatibility and resistance to corrosion make it a favorable choice for implants that require long-term performance without causing adverse reactions.

Tantalum powder also finds applications in the semiconductor industry, where it serves as a substrate for growing thin films of other materials. Its smooth surface and low thermal expansion coefficient make it suitable for precision microelectronics manufacturing.

Lastly, tantalum’s unique magnetic properties, although weak, make it suitable for some magnetic components, particularly in microwave and radio frequency devices.

In summary, tantalum powder is a versatile material with outstanding properties that set it apart from other metals. Its high strength, heat resistance, corrosion resistance, and unique characteristics make it an essential component in numerous industries, including aerospace, electronics, healthcare, and semiconductor technology. As researchers continue to explore new applications, the demand for tantalum powder is expected to grow, reflecting its enduring value in modern technology.

(Metal Ta Powder Tantalum powder)

FAQs of Metal Ta Powder Tantalum powder

Inquiry us