Overview of Tantalum powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Tantalum powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

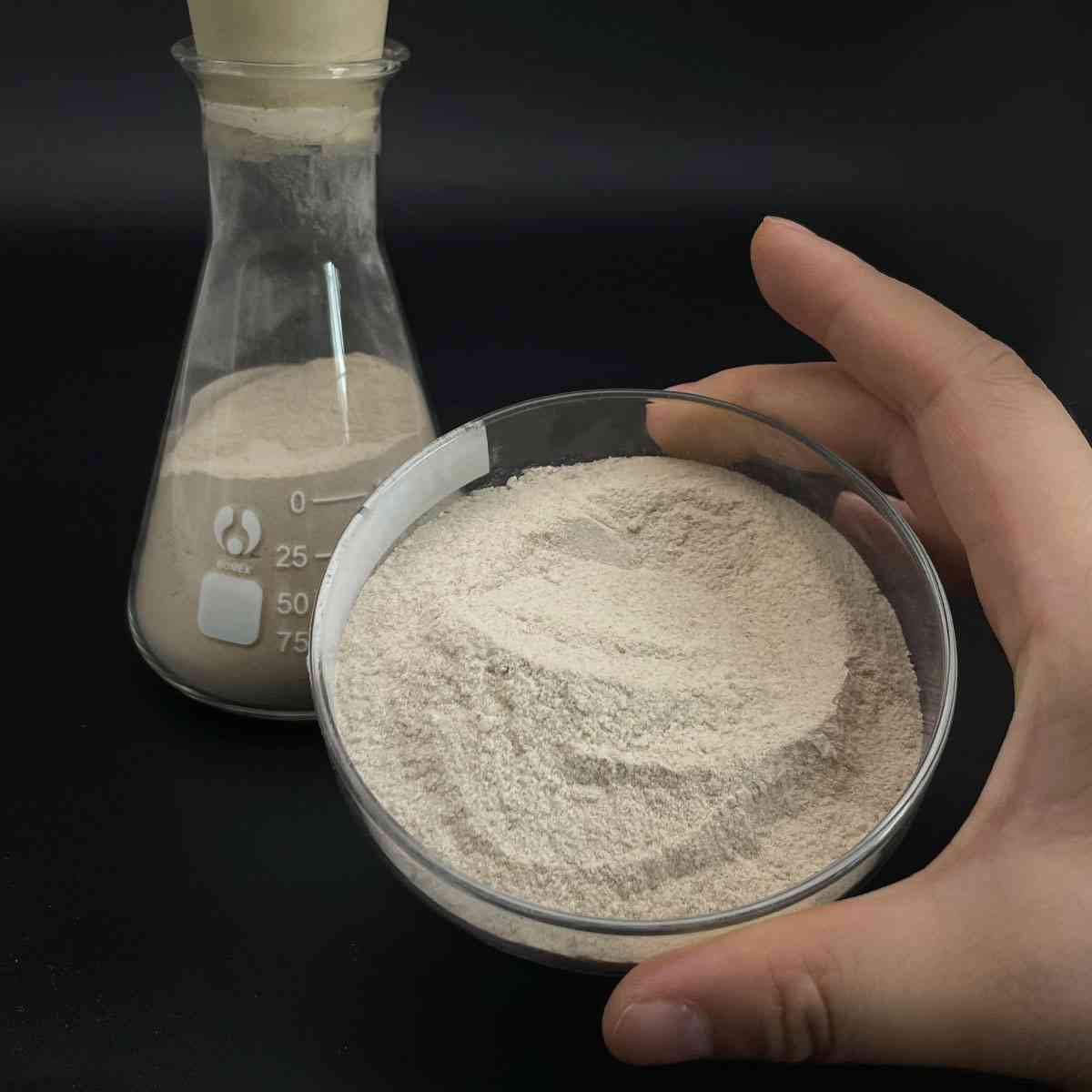

(Tantalum powder)

Parameters of Tantalum powder

Tantalum powder, also known as tantalum metal fines or granules, is a high-performance material with unique properties that make it indispensable in various industries. It is derived from the element tantalum, which is a chemical element with the atomic number 73 and symbol Ta. Tantalum is a rare, lustrous transition metal often referred to as the “noble metal” due to its resistance to corrosion, high melting point, and exceptional strength.

The key parameters of tantalum powder include:

1. Particle Size Distribution: Tantalum powders are available in different particle sizes, ranging from submicron to coarse granules, depending on the intended application. This distribution ensures compatibility with various manufacturing processes like sintering, casting, or as a catalyst support.

2. Purity: Commercially available tantalum powders have a purity level typically above 99.5%, ensuring minimal impurities that could affect performance. Higher purity grades are used in applications where contamination must be strictly controlled.

3. Density: With a density of around 16.65 g/cm³, tantalum powder has a compact structure, which contributes to its high strength and stiffness. This density also impacts the weight of components made from tantalum powder.

4. Melting Point: Tantalum’s melting point is an impressive 3,287°C (5,931°F), making it one of the highest-melting-point elements. This property is crucial for applications that require materials that can withstand extreme temperatures without deforming or losing structural integrity.

5. Chemical Resistance: Tantalum is highly resistant to acids, alkalis, and even molten salts, which makes it ideal for use in harsh chemical environments. This resistance helps prevent corrosion and prolongs the service life of components.

6. Electrical Conductivity: Although not as conductive as copper, tantalum still exhibits good electrical conductivity, making it suitable for applications like capacitors and electronic components where stability and reliability are essential.

7. Thermal Conductivity: Tantalum has excellent thermal conductivity, which facilitates heat dissipation and makes it an attractive material for heat sinks and other thermal management applications.

8. Mechanical Properties: Tantalum powder has high strength, hardness, and toughness, which contribute to its ability to maintain structural integrity under stress. These properties are particularly important in aerospace, automotive, and defense industries.

Applications of Tantalum Powder:

– Electronics: Tantalum capacitors are widely used due to their long-term stability, high capacitance, and low leakage current.

– Aerospace: Tantalum is employed in engine parts, jet engines, and rocket nozzles due to its lightweight and high-temperature resistance.

– Medical Devices: Tantalum is used in implants due to its biocompatibility and non-corrosive nature.

– Chemical Processing: Tantalum’s resistance to corrosion makes it ideal for reactors, pumps, and valves in harsh chemical environments.

– Optical Applications: Tantalum coatings improve the performance of optical components by enhancing reflectivity or reducing absorption.

In summary, tantalum powder is a versatile material characterized by its exceptional properties, such as high purity, durability, and chemical resistance. Its wide range of applications across diverse industries highlights the importance of understanding its key parameters to ensure optimal performance in each specific use case.

(Tantalum powder)

FAQs of Tantalum powder

Inquiry us