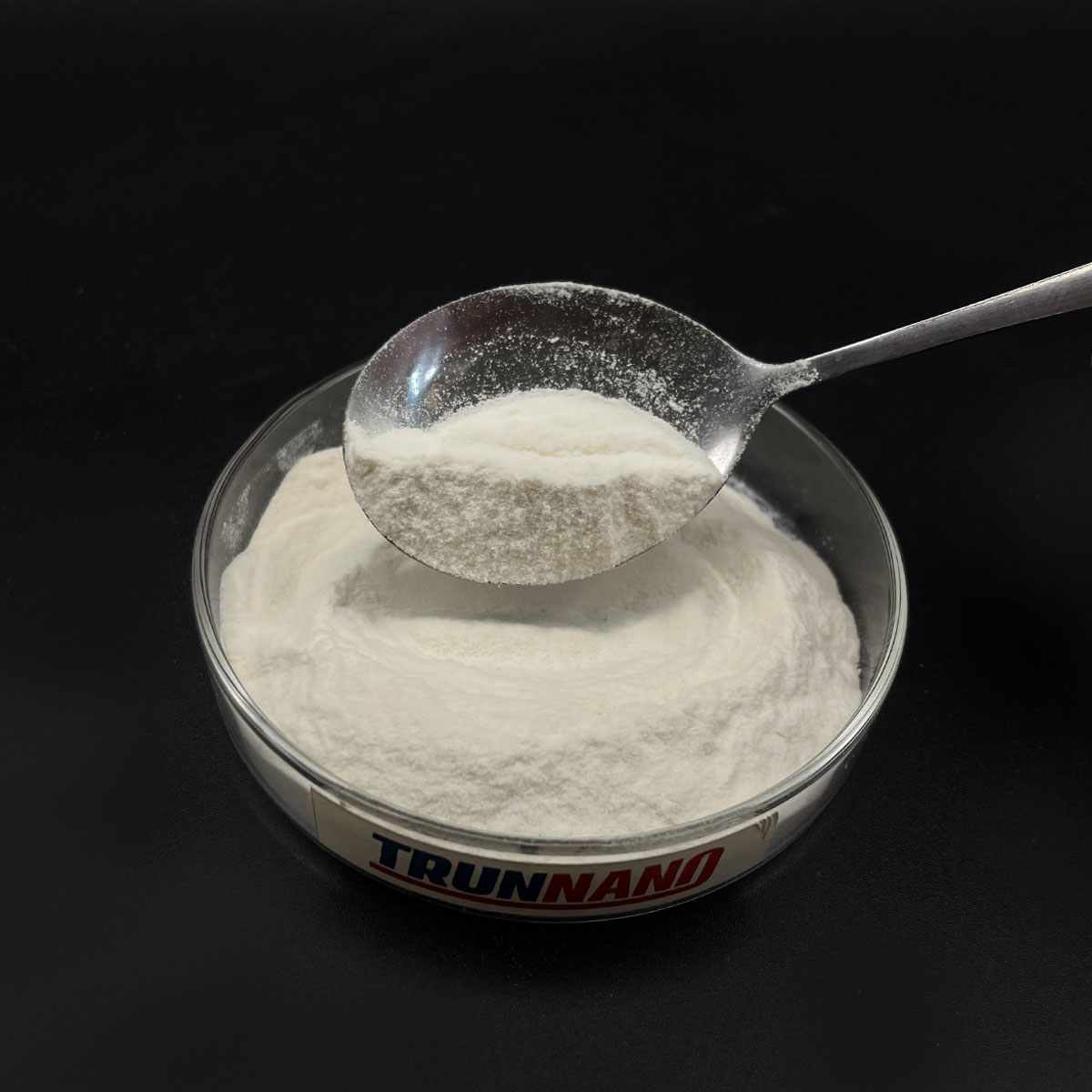

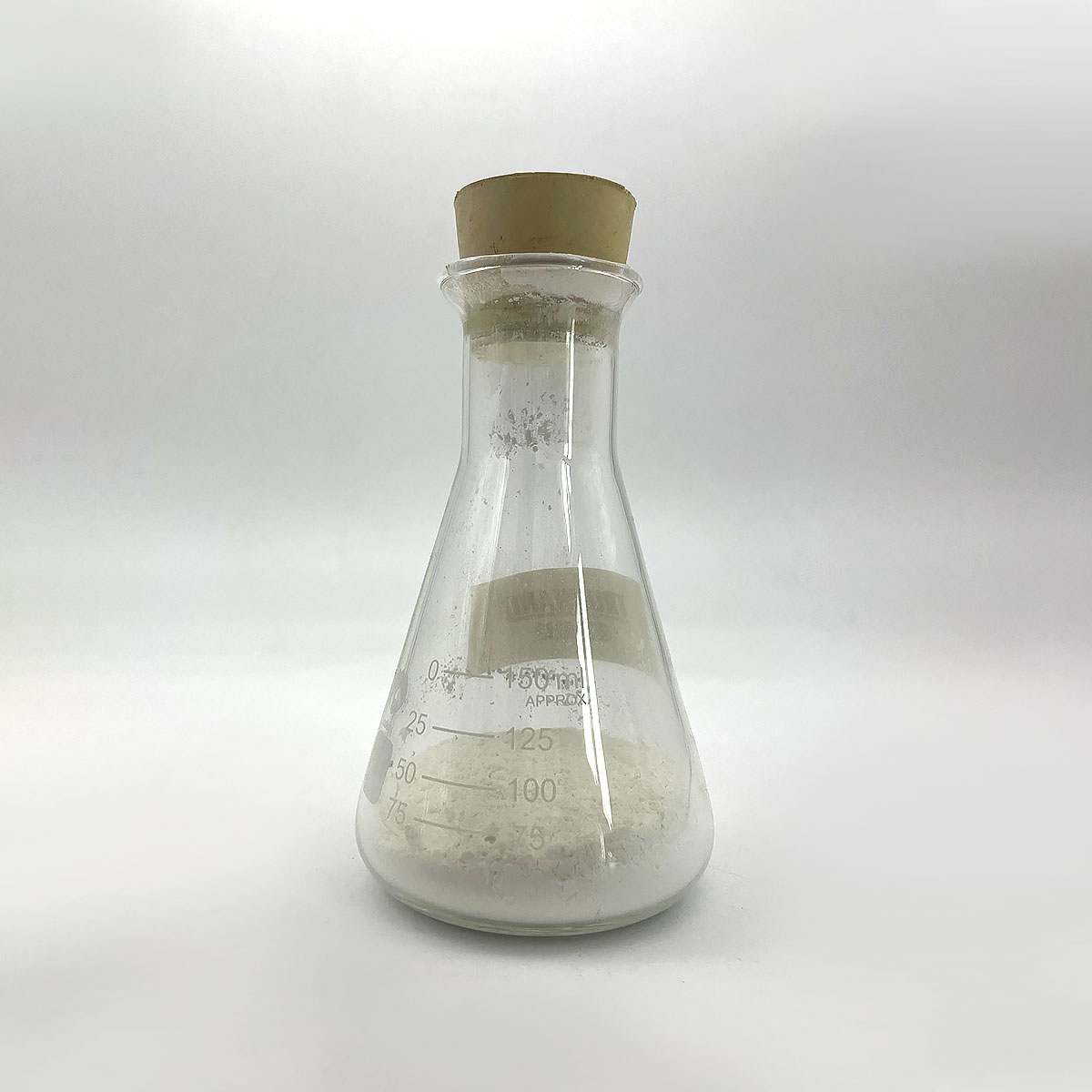

Overview of Solid State Battery Consumables LLZTO Conductive Ceramic Power Lithium Lanthanum Zirconium Tantalum Oxygen Solid Electrolyte

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Solid State Battery Consumables LLZTO Conductive Ceramic Power Lithium Lanthanum Zirconium Tantalum Oxygen Solid Electrolyte

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Solid State Battery Consumables LLZTO Conductive Ceramic Power Lithium Lanthanum Zirconium Tantalum Oxygen Solid Electrolyte)

Parameters of Solid State Battery Consumables LLZTO Conductive Ceramic Power Lithium Lanthanum Zirconium Tantalum Oxygen Solid Electrolyte

A solid-state battery, also known as a lithium-ion ceramic battery or all-solid-state battery, is an advanced energy storage device that utilizes a solid electrolyte instead of the conventional liquid or gel electrolytes found in lithium-ion batteries. The key component in these batteries is the LLZTO (Lithium-Lanthanum-Zirconium-Tantalum-Oxygen) conductive ceramic power material, which plays a pivotal role in their performance.

LLZTO, short for Lithium-Lanthanum Zirconium Titanate Oxide, is a complex ceramic compound primarily composed of lithium, lanthanum, zirconium, tantalum, and oxygen. It forms a perovskite structure, which is known for its excellent ionic conductivity and high thermal stability. This structure allows for efficient lithium-ion transport without the risk of dendrite growth, which is a common issue in conventional lithium-ion batteries.

The solid electrolyte in LLZTO-based batteries offers several advantages over conventional designs. Firstly, it eliminates the flammability and safety concerns associated with liquid electrolytes, as ceramics are inherently non-flammable. Secondly, solid electrolytes have higher operating temperatures, enabling faster charging and discharging rates without compromising cell life. Thirdly, they can potentially offer better cycle life due to the absence of degradation caused by dendrite formation.

The performance parameters of an LLZTO-based solid-state battery include:

1. **Electrical Conductivity**: LLZTO’s high ionic conductivity is crucial for fast charge-discharge cycles. The higher the conductivity, the quicker ions can move through the material, leading to shorter charging times and improved efficiency.

2. **Thermal Stability**: The ceramic nature of LLZTO provides excellent thermal stability, allowing the battery to operate safely over a wide temperature range without significant performance degradation.

3. **Resistance to Dendrite Formation**: The solid electrolyte prevents the formation of metallic lithium dendrites, which can cause internal shorts and safety hazards in traditional batteries. This results in longer cycle life and improved reliability.

4. **Energy Density**: Although initially lower than liquid electrolyte-based batteries, ongoing research is focused on enhancing the energy density of LLZTO solid-state batteries through advancements in ceramic synthesis and composite materials.

5. **Safety**: As mentioned earlier, the absence of flammable liquids makes solid-state batteries safer during charging, discharging, and even in case of accidents.

6. **Compatibility**: Ensuring compatibility between the ceramic electrolyte and the lithium metal anode is a challenge that researchers are actively addressing. Proper interface engineering is essential for stable operation.

In conclusion, the LLZTO conductive ceramic power material is a critical enabler for solid-state batteries, offering enhanced safety, performance, and potential for future energy storage solutions. While there are still challenges to overcome, the promising properties of this material make it a key focus area in the quest for next-generation energy storage technologies.

(Solid State Battery Consumables LLZTO Conductive Ceramic Power Lithium Lanthanum Zirconium Tantalum Oxygen Solid Electrolyte)

FAQs of Solid State Battery Consumables LLZTO Conductive Ceramic Power Lithium Lanthanum Zirconium Tantalum Oxygen Solid Electrolyte

Inquiry us